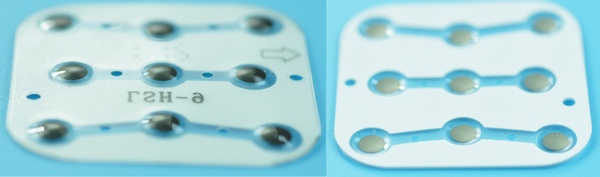

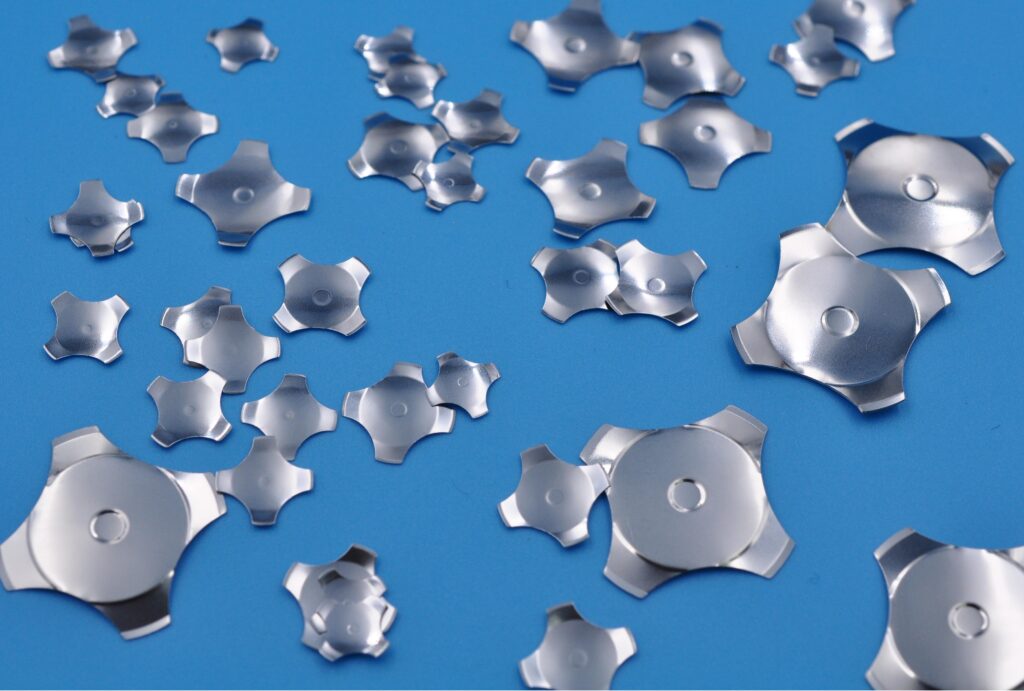

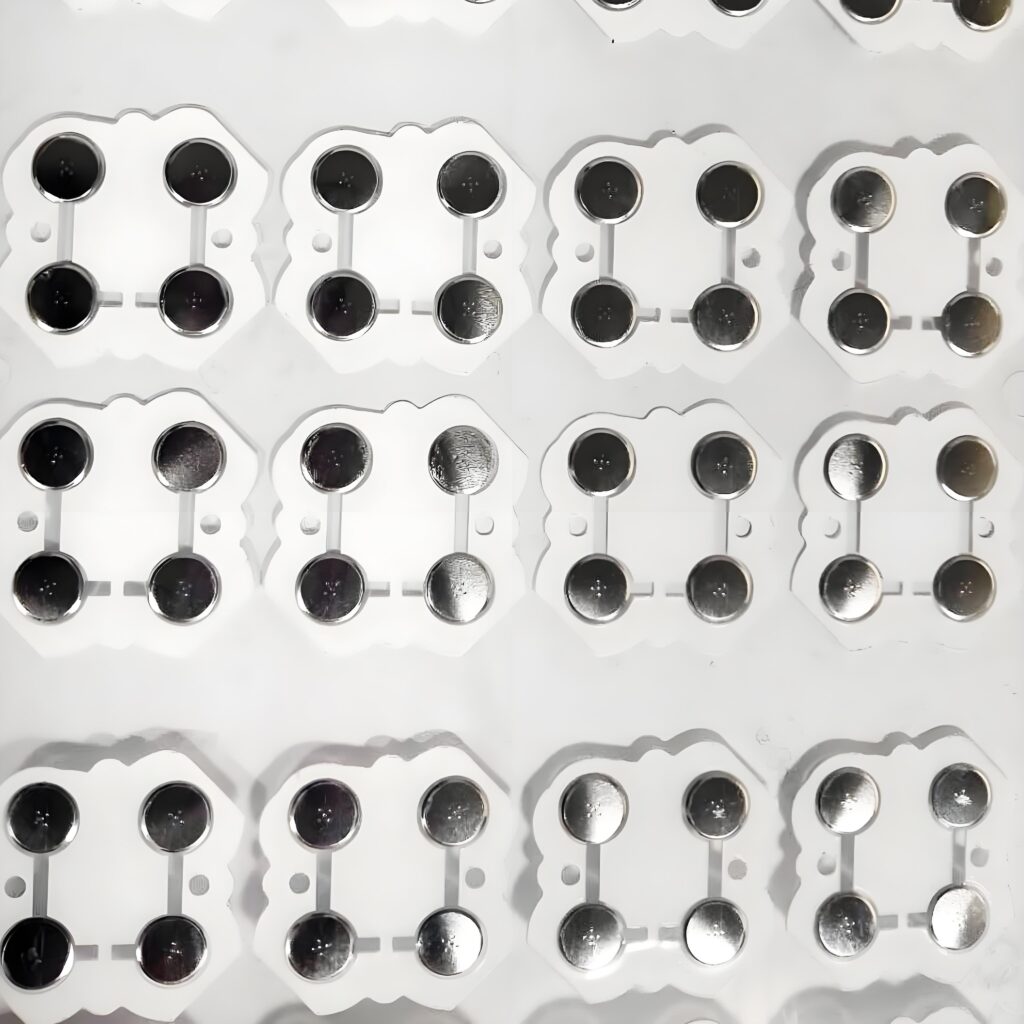

What is a silver switch? The core component of a silver switch is a silver-plated metal spring. Metal dome is usually made of materials with good elasticity and conductivity, such as stainless steel, copper alloy, etc., and then is plated with a layer of silver on its surface. Silver is a metal with excellent electrical conductivity. Plating it on the surface of the metal spring can significantly improve the conductive performance of the switch.

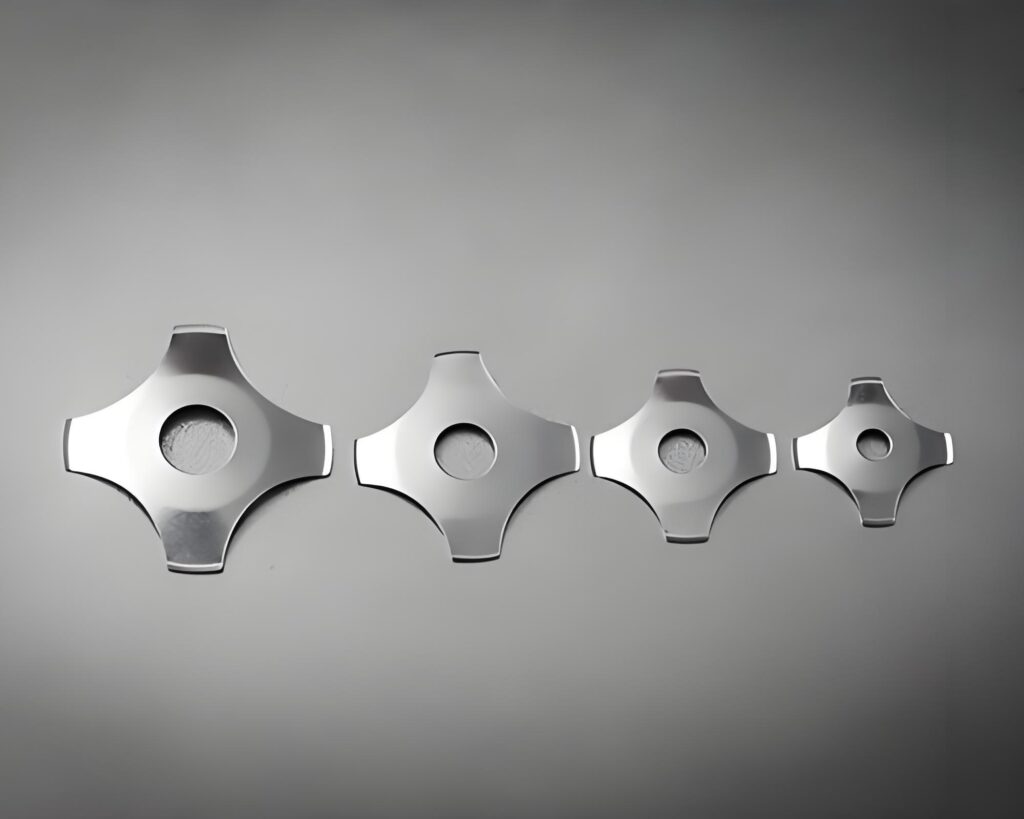

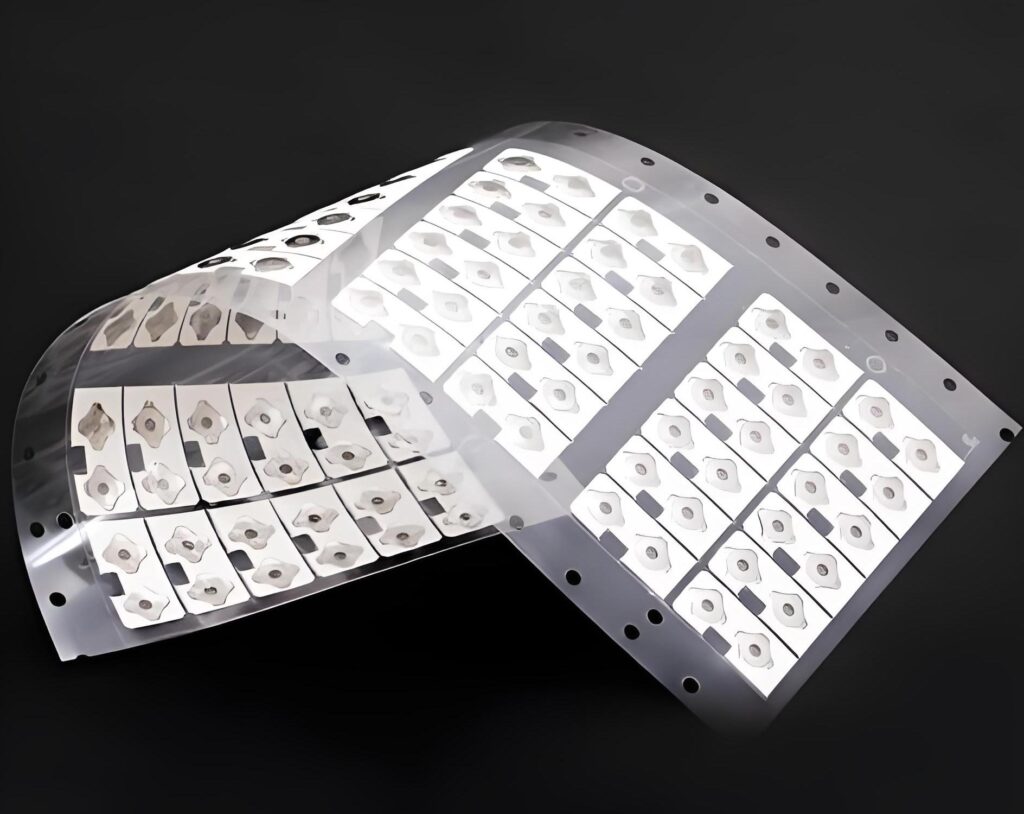

BEST Technology supports the production and design of different types of metal dome switches, using stainless steel 301 or 304 materials for production and supporting tin, gold, silver and other processing processes on the dome to meet actual needs.

What is a silver dome switch?

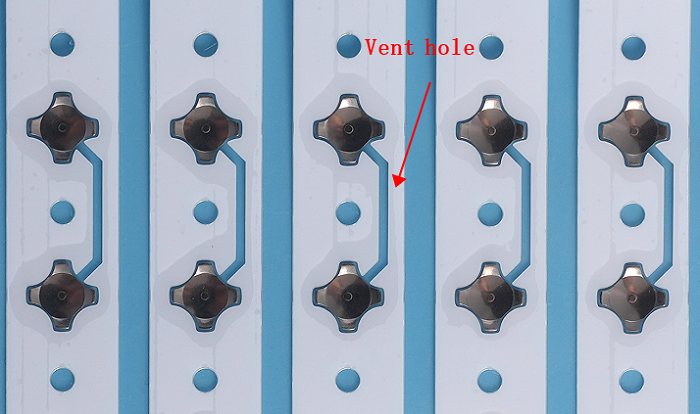

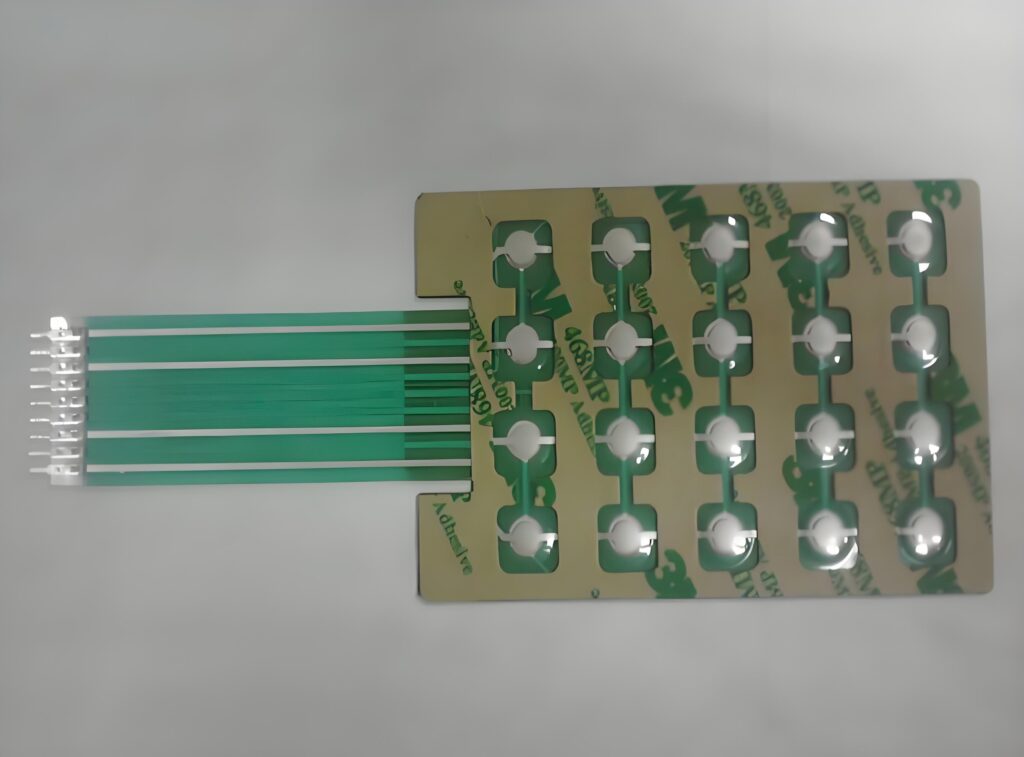

Silver-plated metal dome switch is an electrical device that uses silver-plated metal dome in the switch. This kind of switch usually consists of contact pieces, contacts, spring pieces, etc., among which the metal spring piece is one of the core components of the switch. The metal dome plays the role of conducting and disconnecting circuits in the switch, and its performance directly affects the electrical performance and service life of the switch.

The functions and advantages of silver-plated metal dome:

- Conductive properties: Silver is a good conductive metal with good electrical and thermal conductivity. The silver-plated metal dome can significantly improve the conductive performance of the switch and reduce resistance, thus improving the response speed and stability of the switch.

- Mechanical properties: Silver has good mechanical properties and corrosion resistance, which can enhance the durability and stability of the dome and extend the service life of the switch.

- Appearance quality: The silver plating layer can reflect light, giving the switch better visual effects and aesthetics.

Application scenarios of silver-plated metal dome switches:

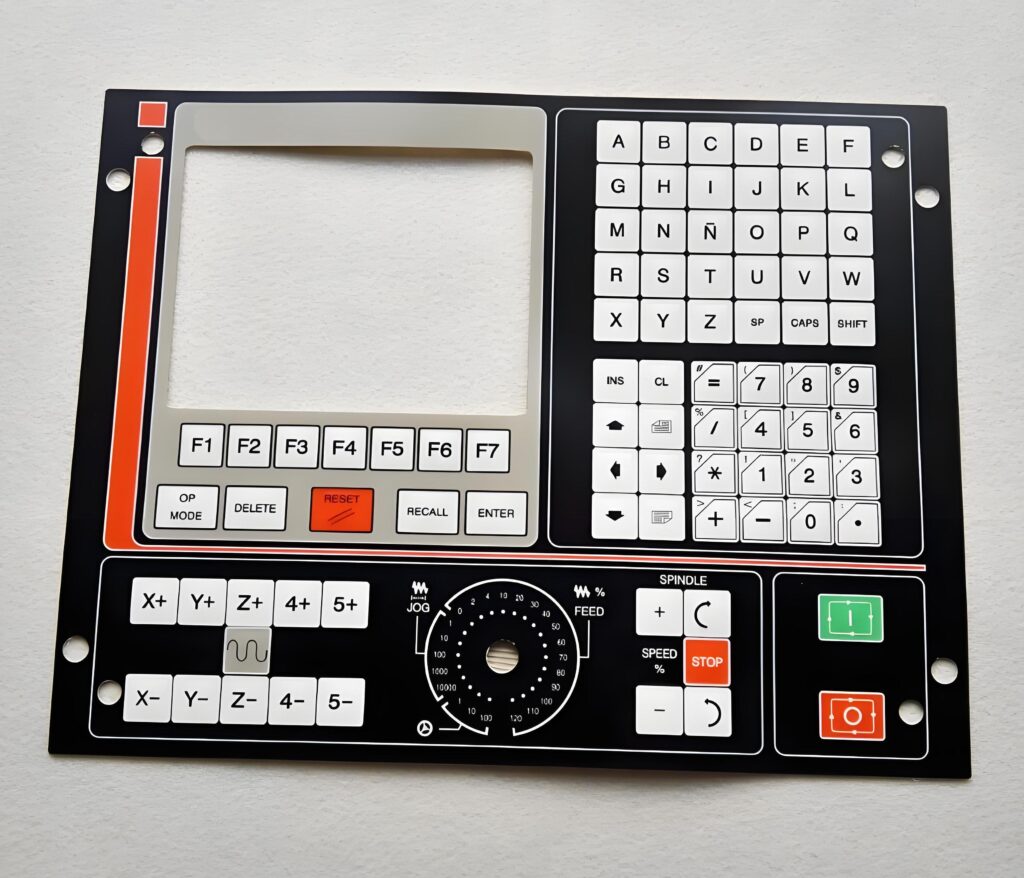

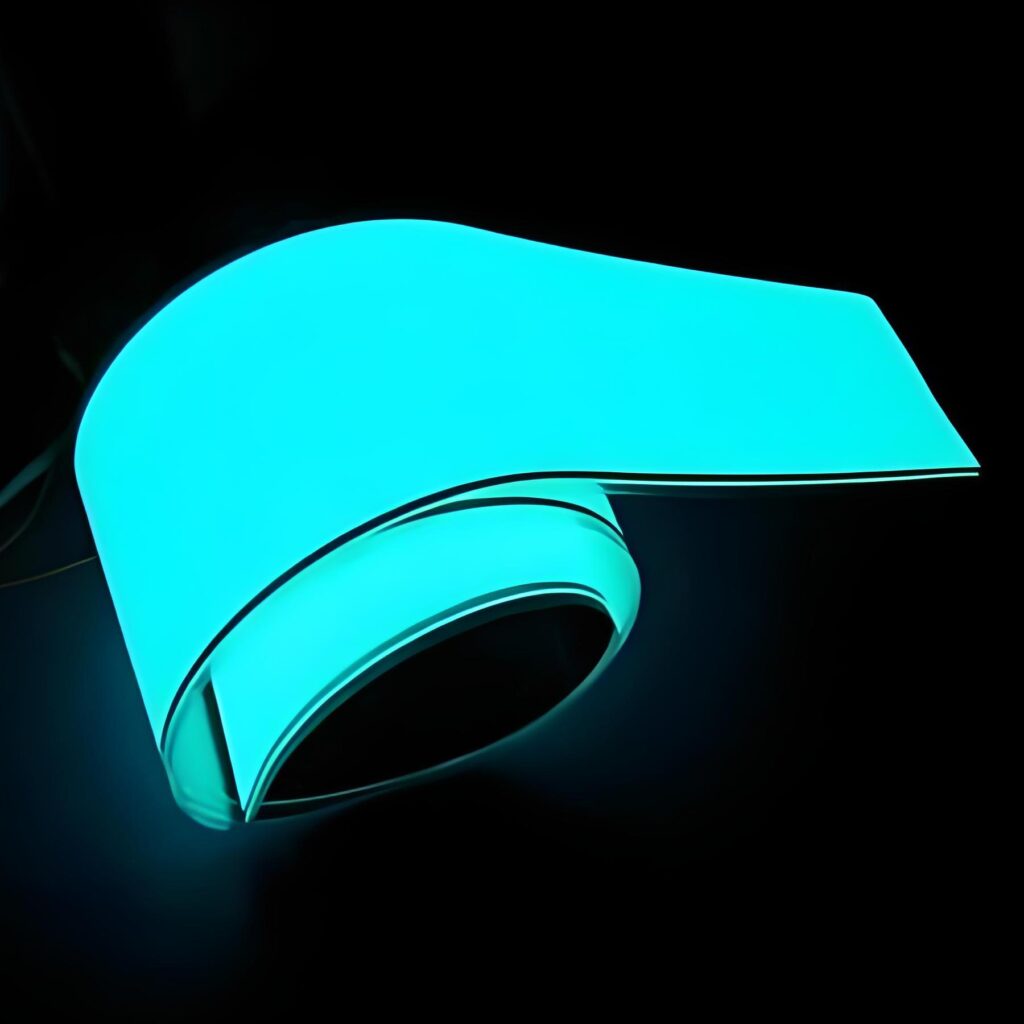

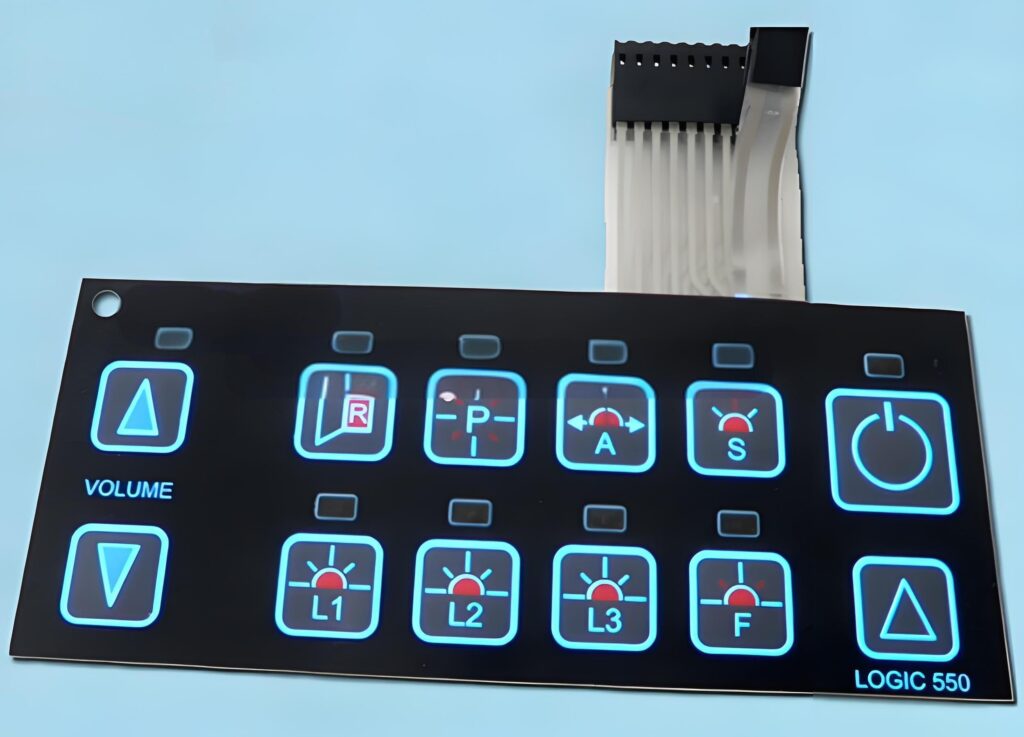

Silver-plated metal dome switches are widely used in various electrical equipment, such as lamps, household appliances, industrial equipment, etc. Due to its excellent electrical conductivity and mechanical properties, silver-plated metal dome switches are particularly suitable for applications that require high strength conductivity and high durability.

Manufacturing process of silver-plated metal dome switch:

There are many methods of silver plating, the commonly used ones include electroplating, chemical plating and hot plating. Among them, electroplating is one of the most commonly used methods. By placing an object in an electrolyte and connecting the object to a power source through a capacitor, electrons deposit a layer of metal on the surface of the object to form a metal film.

To sum up, silver-plated metal dome switches have been widely used in various electrical equipment due to their excellent electrical conductivity, mechanical properties and aesthetics.

What materials does the dome switch consist of?

The main materials of dome switches include stainless steel 301 or 304. These materials have the characteristics of ultra-thin (0.05mm-0.1mm thickness) and ultra-thick (generally higher hardness), and are usually used to make button springs and metal springs.

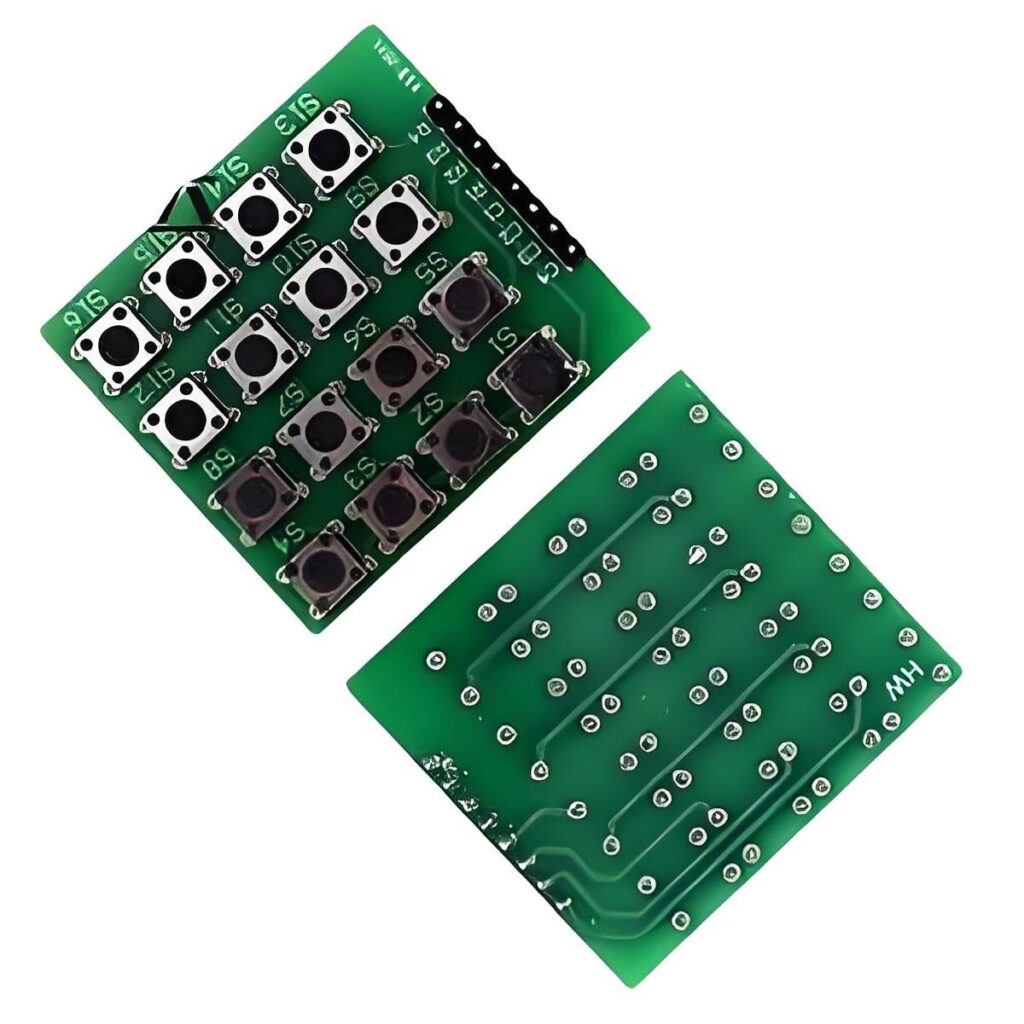

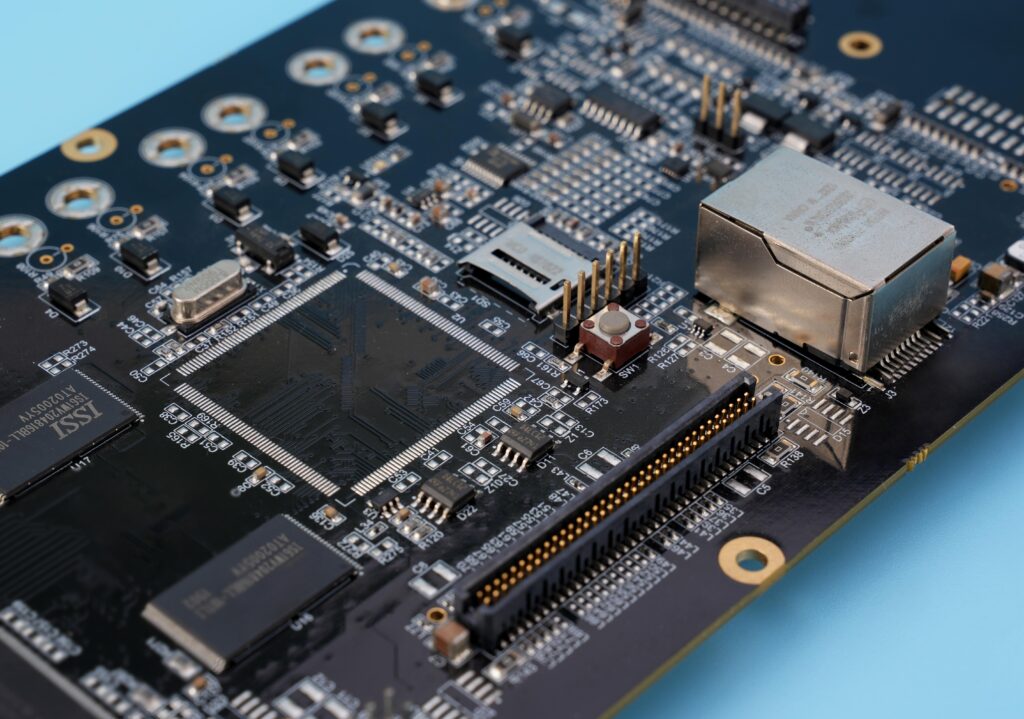

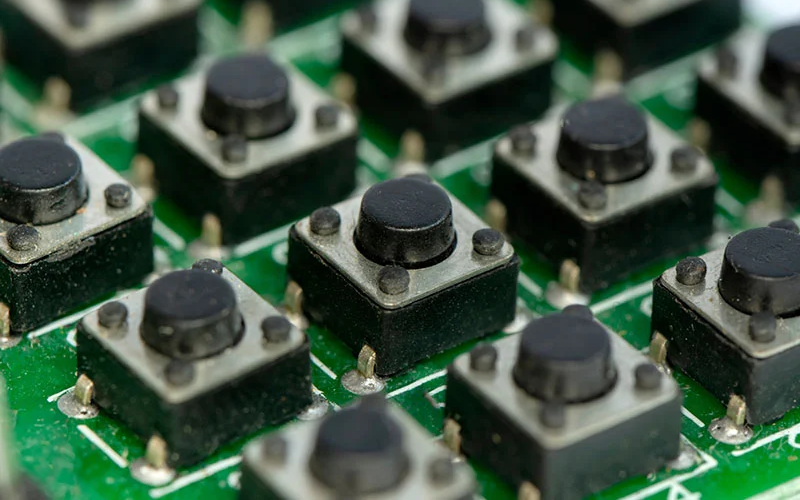

The working principle of the dome switch is to press to make the center point of the dome concave and contact the circuit on the PCB (Printed Circuit Board), thus forming a loop, allowing current to pass through, and making the product work normally.

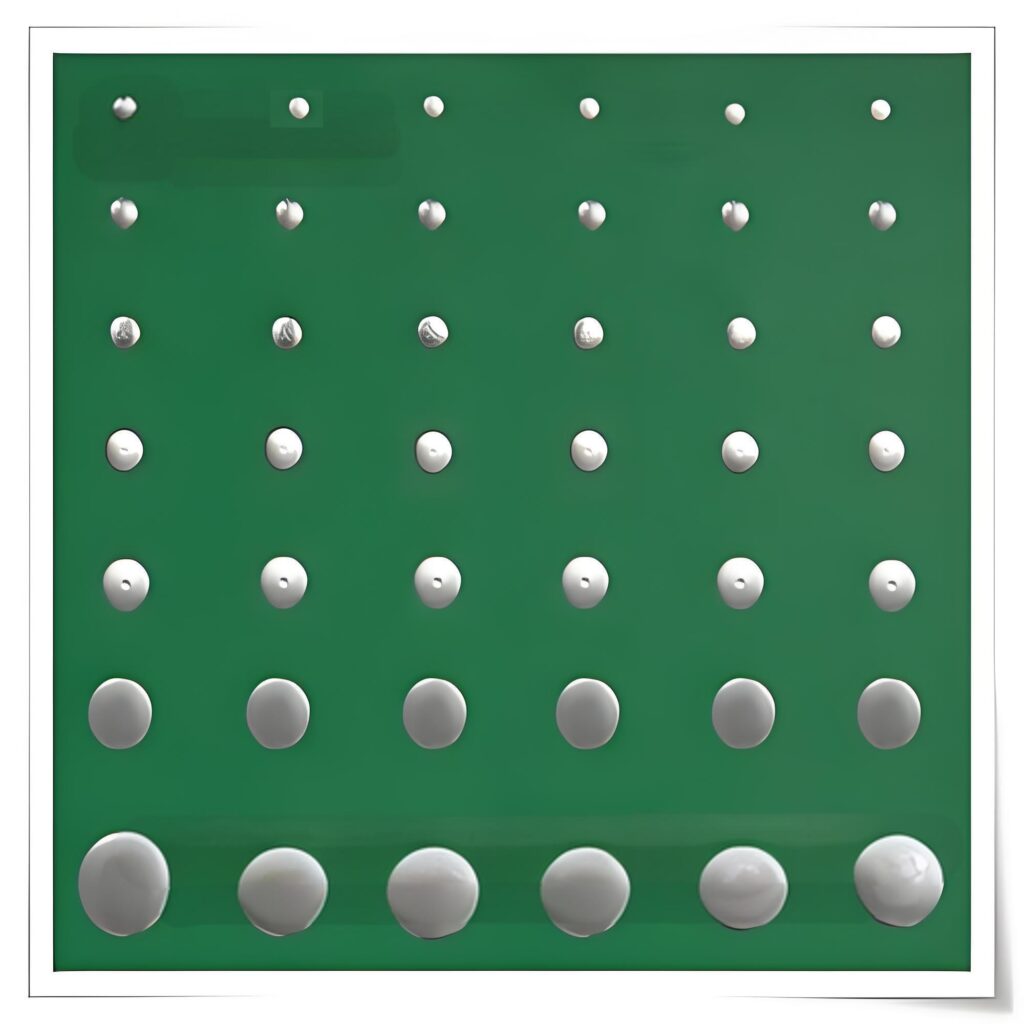

Dome switches are widely used in membrane switches, contact switches, PCB boards, FPC boards, medical equipment and other products. Common metal dome shapes include circles, crosses, triangles, ovals, etc. These shapes of dome are suitable for different application scenarios and needs.

Can the dome switch be silvered?

The dome switch can be silver-plated. Silver plating is an electrochemical process that mainly uses the principle of electrolysis to deposit a layer of silver on the surface of the dome switch. Put the dome switch into the plating tank, and by controlling parameters such as current density, plating time, temperature, etc., the thickness and quality of the silver plating layer can be accurately controlled.

Silver is a very conductive metal and has a very low resistivity. Silver plating on the dome switch can significantly reduce the contact resistance between the dome and the contact point.

Silver plating can form a protective film on the surface of the dome to prevent the dome from being eroded by external environmental factors (such as oxygen, moisture, corrosive gases, etc.). In some harsh working environments, silver-plated dome switches can better maintain their performance.

The surface of the silver-plated dome switch is brighter and more beautiful, which has certain advantages in some electronic equipment with high appearance requirements (such as consumer electronics products). In addition, the silver plating can also improve the solderability of the dome switch.

What are silver switches good for?

The switch made of silver-plated metal spring has the following main uses and advantages:

1. Improve electrical conductivity: Silver is a good conductive metal with good electrical and thermal conductivity. It can effectively improve the electrical conductivity and mechanical properties of the switch, ensuring the stability and reliability of the switch in various electrical applications.

2. Enhance mechanical properties and corrosion resistance: Silver has good mechanical properties and corrosion resistance. The silver-plated metal dome can withstand greater pressure and wear, extending the service life of the switch.

3. Improve appearance quality: The silver-plated surface can reflect light, giving the switch a better visual effect, better aesthetics and decoration.

4. Wide range of applications: Silver-plated metal dome is widely used in various electronic devices. It has small size, long life, flexible operation, stable and reliable performance, and is suitable for operating signal input of various electronic devices.

In summary, switches made of silver-plated metal dome have significantly improved electrical conductivity, mechanical properties, corrosion resistance and appearance quality, and are widely used in various electronic devices to meet the needs of different application scenarios. .

What are the characteristics of silver switches?

The main features of silver-plated metal dome switches include good electrical conductivity, strong oxidation resistance, long service life and low resistance.

Silver-plated metal dome switches have very good electrical conductivity because silver is an excellent conductor and can provide stable current transmission. In addition, the silver plating layer can effectively prevent the metal dome from oxidation and extend the service life of the switch. The silver plating layer can also reduce resistance and improve the response speed and stability of the switch.

Due to its excellent electrical conductivity and anti-oxidation capabilities, silver-plated metal dome switches are often used in situations where high-quality electrical conductivity is required, such as precision instruments, aviation instruments and other fields. These fields have high requirements on the stability and reliability of switches, and silver-plated metal dome switches can meet these needs.

Compared with galvanized switches, silver-plated metal dome switches have more advantages in conductive performance and anti-oxidation, but the price may be higher. Although galvanized switches also have good corrosion resistance, their conductive properties and anti-oxidation capabilities are not as good as silver-plated switches.

In summary, silver-plated metal dome switches are suitable for high-end electrical appliance manufacturing fields that require high conductive properties due to their excellent conductive properties, anti-oxidation capabilities and long life.

In short, as an important electronic component, silver dome switches play an important role in electronic equipment and systems due to their good conductivity, reliable elastic recovery, corrosion resistance and oxidation resistance.