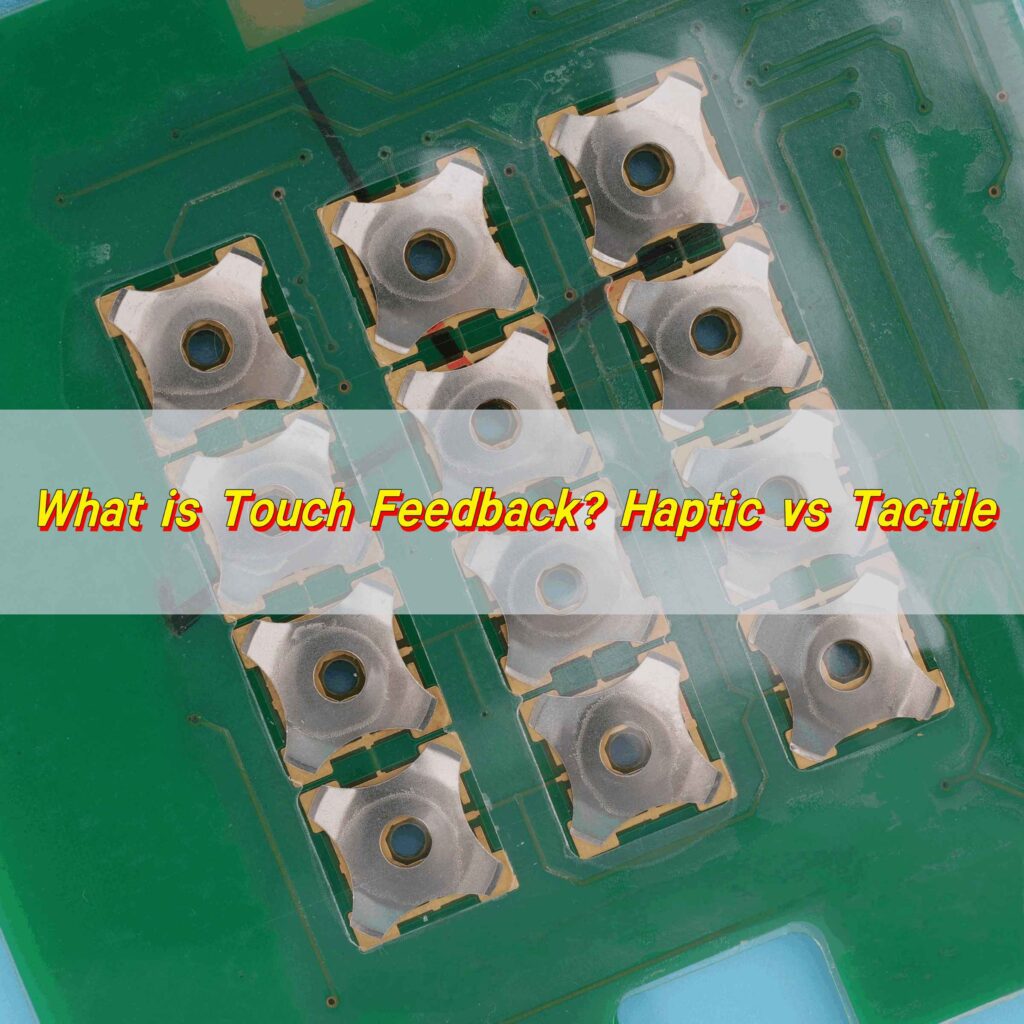

What is Touch Feedback? Touch feedback is a technology that uses vibration, touch and force feedback to transmit tactile information. Touch is the sense of physical stimulation, including pressure, vibration, temperature, etc. Metal dome switches play an important role in this field. They open and close the circuit through the deformation of the metal dome, providing users with clear tactile feedback.

What is haptic feedback?

Haptic feedback refers to the use of force, vibration, or motion to simulate a touch-based response. It creates a more immersive interaction between users and their devices. This type of feedback is common in smartphones, game controllers, and even medical equipment.

When you type on a touchscreen keyboard, feel a buzz from your smartwatch, or sense a vibration while playing a game, that’s haptic feedback in action. It enhances the experience by making interactions feel real.

One of its key advantages is its ability to simulate textures and resistance. Advanced haptic systems can make digital surfaces feel like rough stone, soft fabric, or even liquid movement. This level of realism has transformed industries like gaming, virtual reality, and automotive controls.

What is tactile feedback?

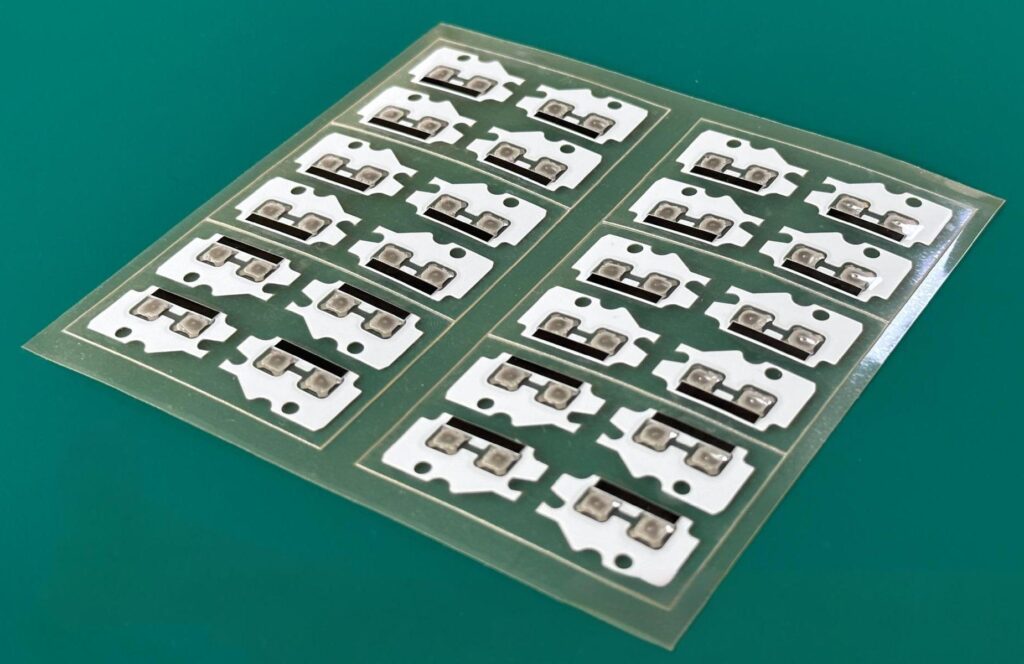

Tactile feedback is the physical sensation you feel when pressing a button, key, or switch. It gives a mechanical response to confirm an action. Unlike haptic feedback, which relies on vibrations or motion, tactile feedback is based on direct physical resistance.

A simple example is a mechanical keyboard. When you press a key, you feel a distinct click or bump. That’s tactile feedback at work. This type of feedback is preferred in applications where precision is essential, such as industrial equipment, medical devices, and control panels.

Another common example is a remote control. Pressing the buttons provides a noticeable response, ensuring the input was registered. This helps users operate devices without looking, improving accuracy and efficiency.

What is the meaning of touch feedback?

Touch feedback is an umbrella term that covers both haptic and tactile responses. It refers to any physical sensation given by a device to confirm an interaction. This feedback is crucial for improving user experience. It makes interactions more intuitive and prevents errors.

For instance, a touchscreen without feedback can feel unresponsive. Users might press a button multiple times, unsure if the action was registered. With touch feedback, a vibration, click, or resistance confirms the input instantly.

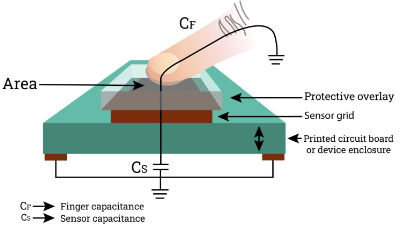

What is haptic feedback on keypress?

Haptic feedback on keypress is the vibration or sensation felt when pressing a virtual keyboard or touchscreen button. It mimics the feeling of pressing a physical key, making digital typing more natural.

Smartphones often use this feature to improve typing accuracy. Without it, typing on a flat screen feels lifeless. The subtle vibrations help users recognize each keystroke, reducing errors and enhancing speed.

Many modern laptops also integrate haptic feedback into touchpads. Instead of traditional mechanical buttons, they use vibrations to simulate a clicking sensation. This provides the same physical confirmation without requiring moving parts.

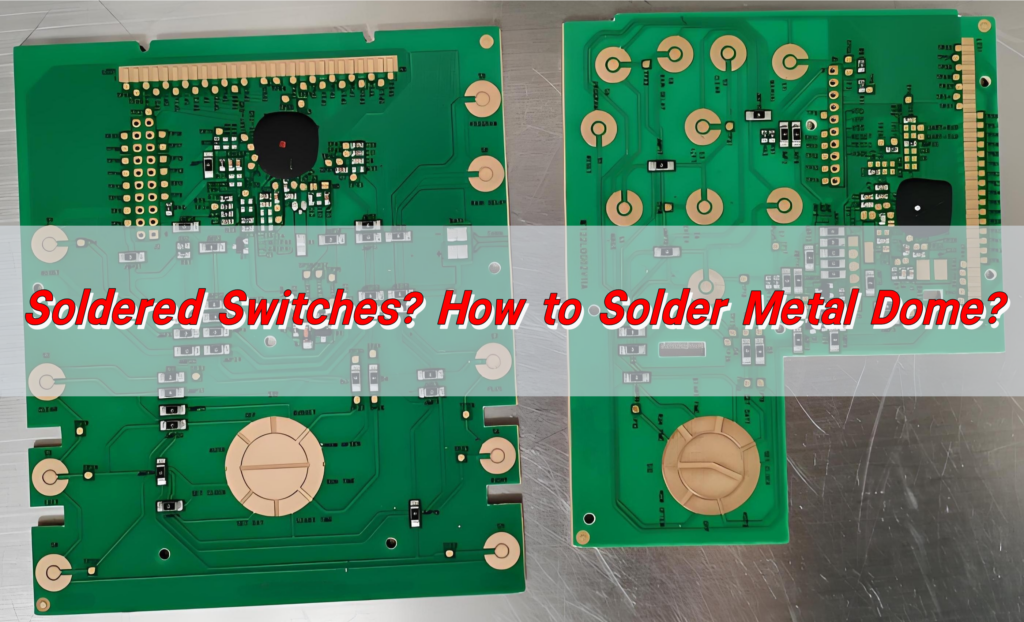

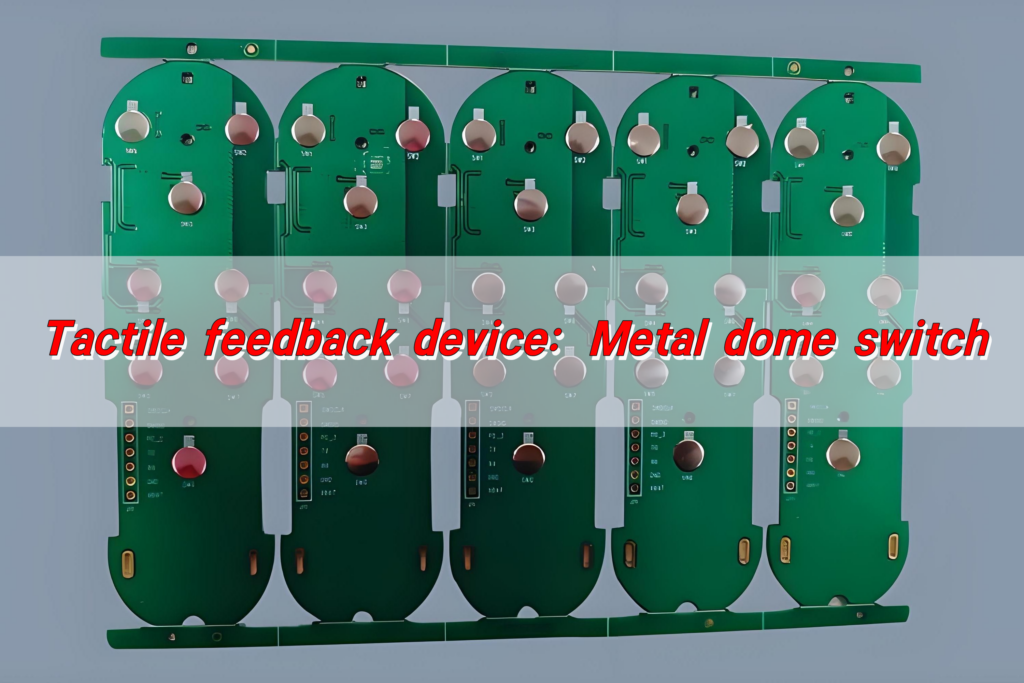

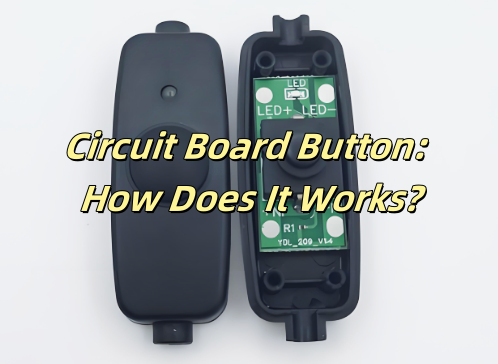

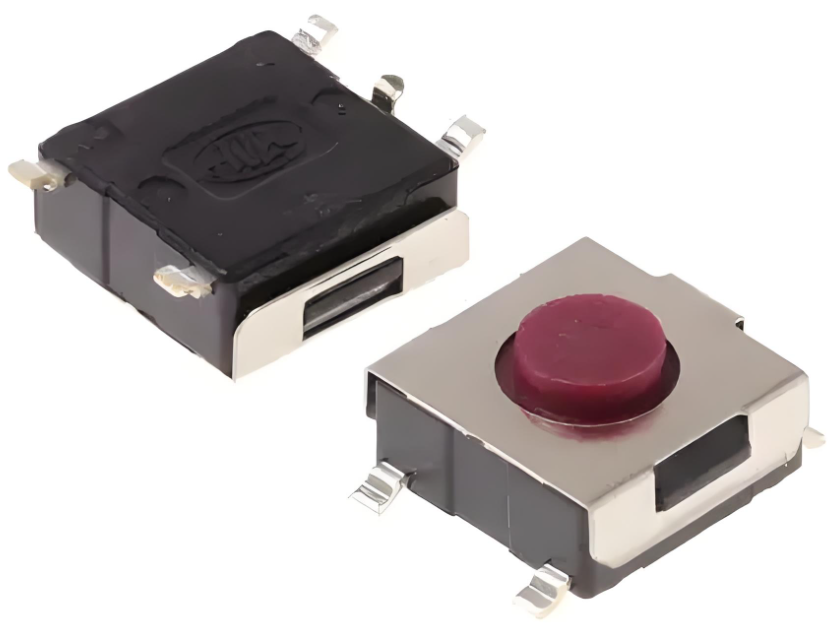

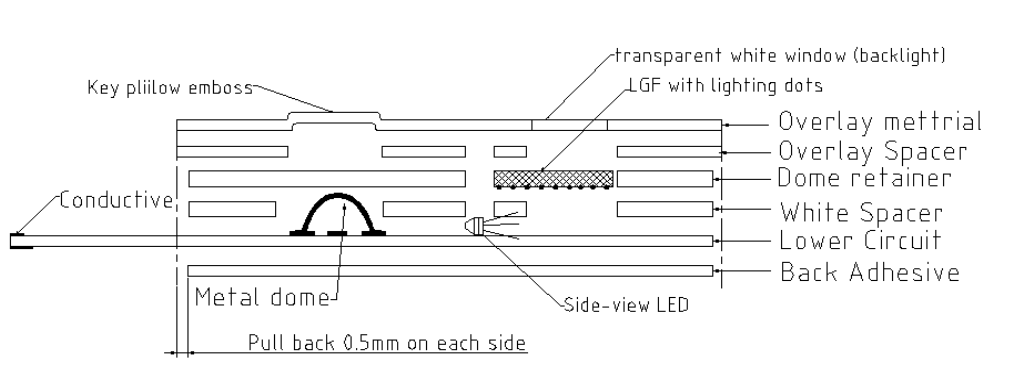

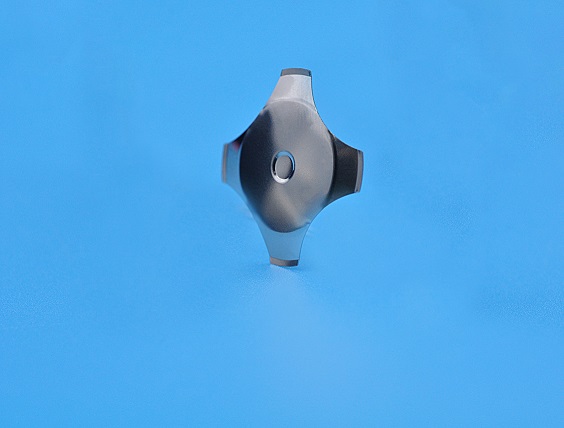

Does the metal dome have tactile feedback?

Yes, metal domes provide excellent tactile feedback. They are widely used in membrane switches, medical devices, and industrial equipment. When pressed, they collapse and then snap back, creating a crisp, responsive feel.

This design ensures a reliable and satisfying click with each press. The strong tactile response improves precision, making metal domes ideal for critical applications. Users can feel each input clearly, reducing the chance of accidental presses.

The durability of metal domes also makes them superior to other types of switches. They maintain their tactile feedback even after millions of cycles, ensuring long-term performance.

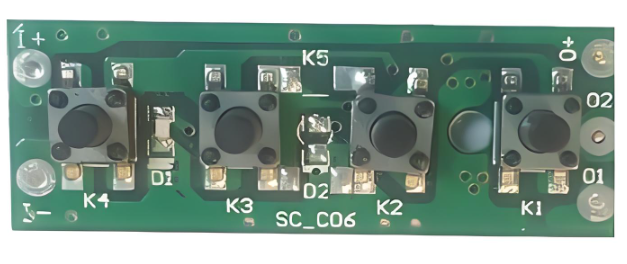

Is the metal dome switch a tactile switch?

Yes, metal dome switches fall under the category of tactile switches. They are designed to give a distinct physical response when pressed. Unlike soft-touch buttons or capacitive touch surfaces, they provide immediate and clear feedback.

This makes them ideal for applications where accuracy is crucial. Medical devices, industrial machines, and aerospace controls rely on these switches for precise operation. The ability to feel each press ensures that inputs are registered correctly.

Metal dome switches are also preferred for their durability. They last much longer than rubber or silicone-based switches, making them a cost-effective choice. Their tactile consistency remains strong even after extensive use.

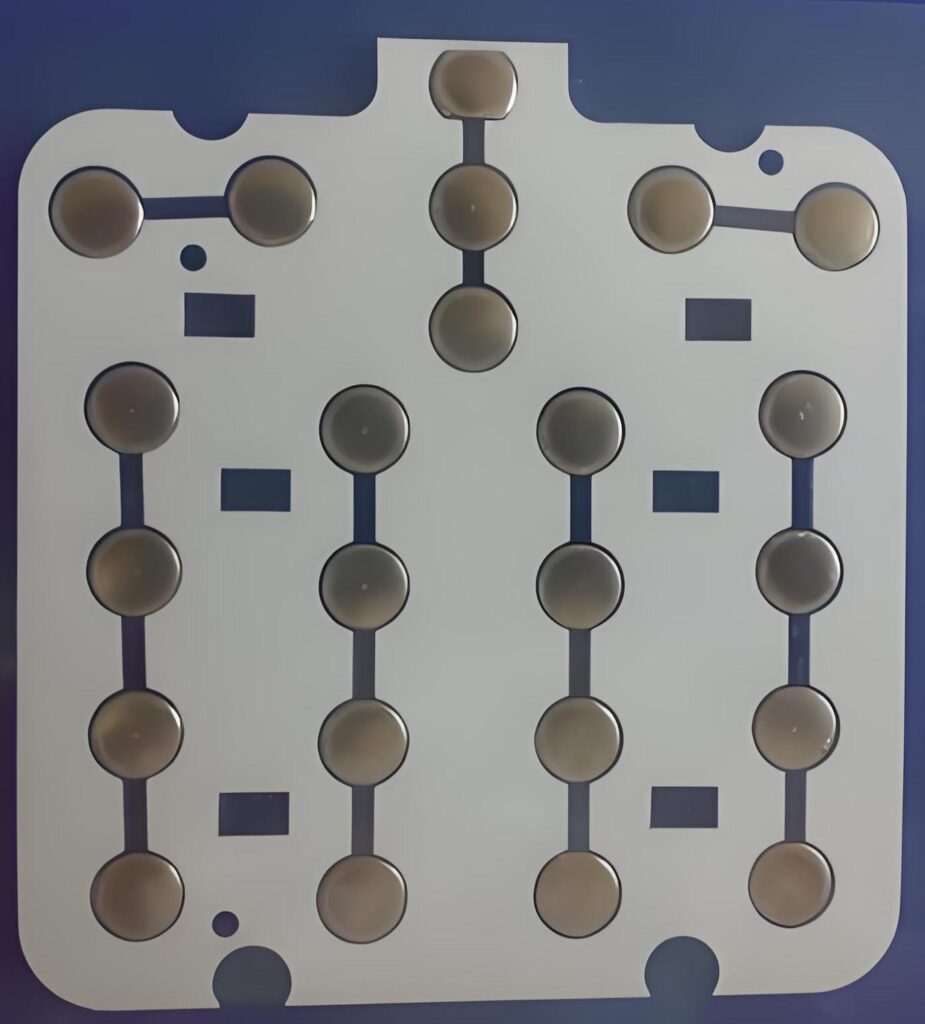

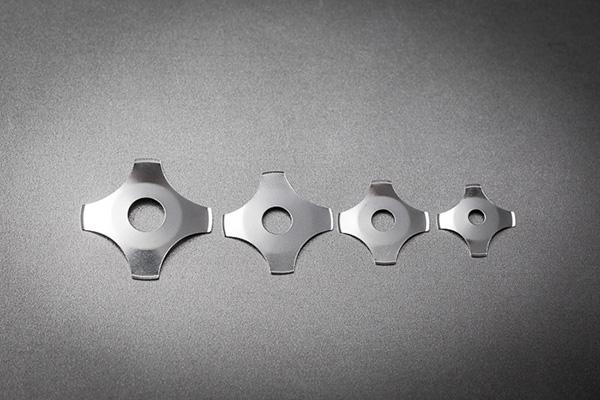

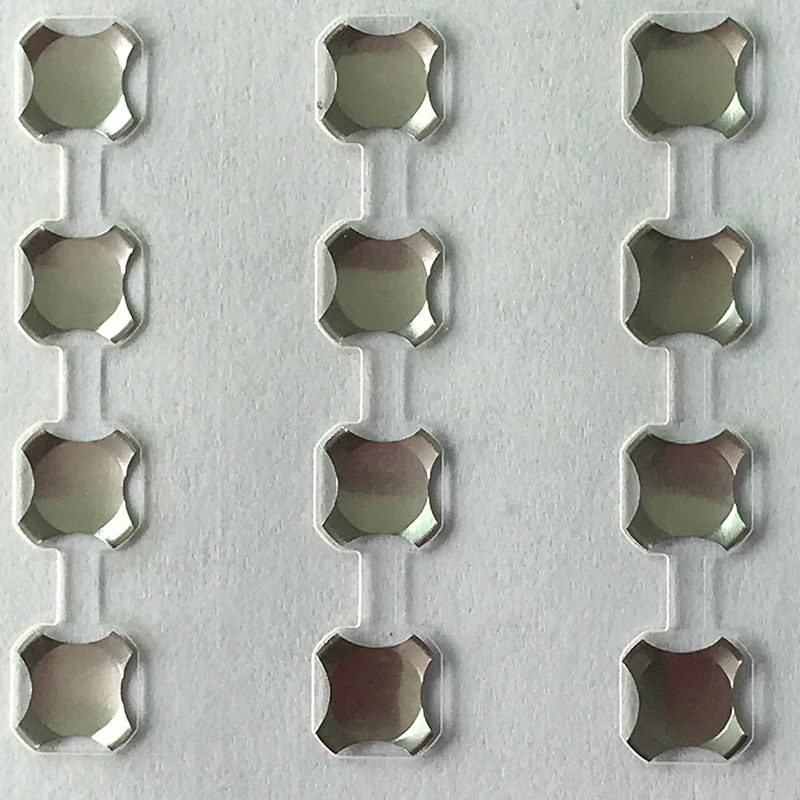

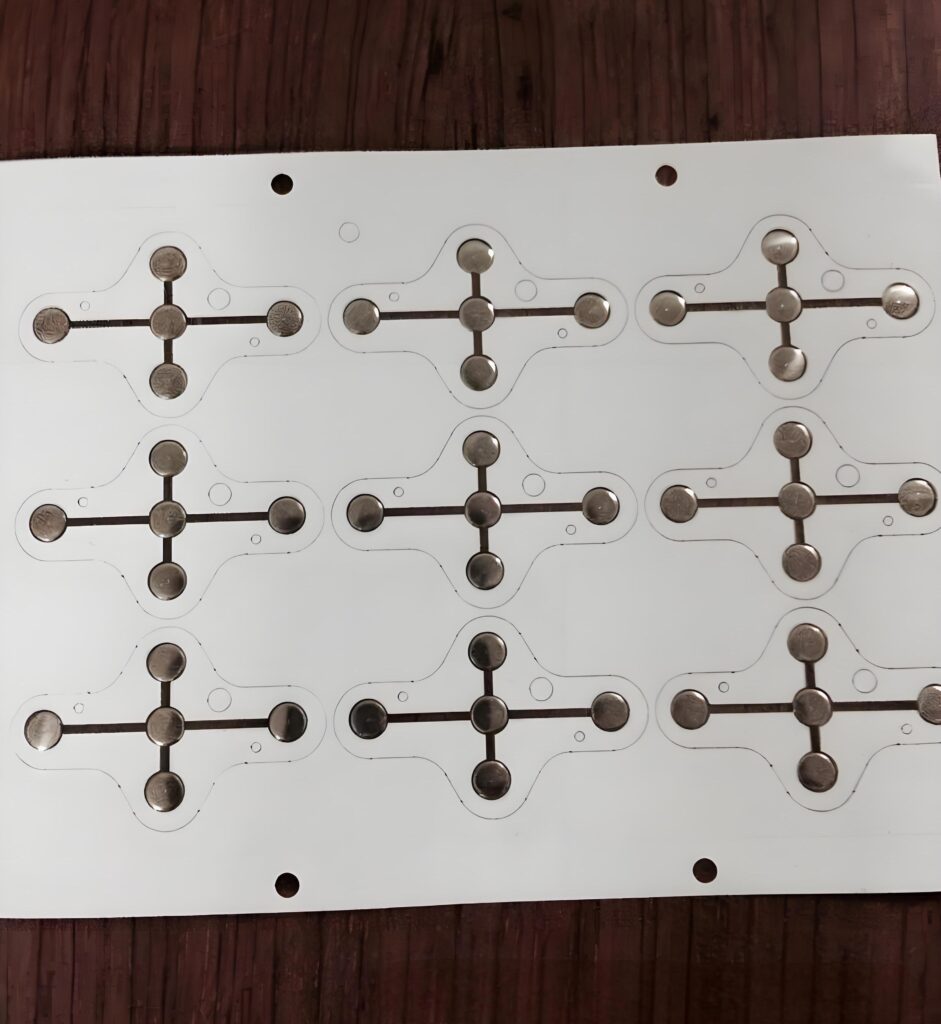

Can the tactile feedback of the metal dome be adjusted?

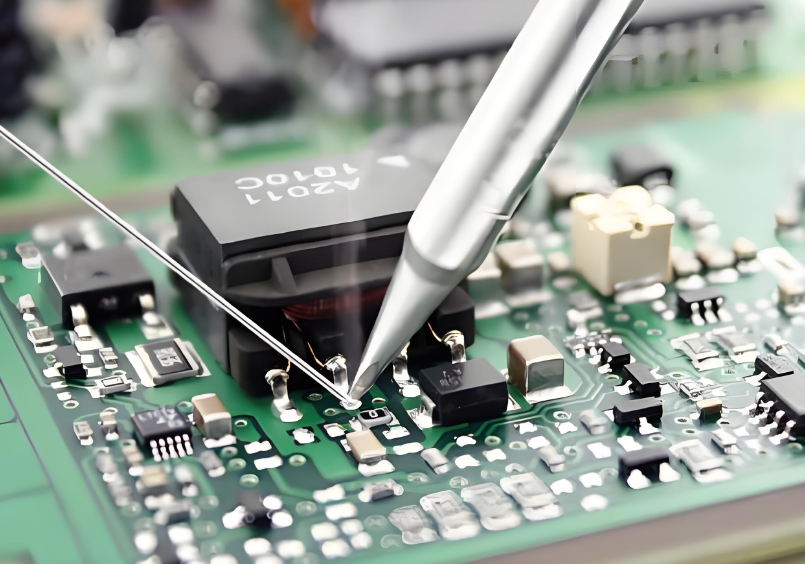

Yes, the tactile feedback of a metal dome can be adjusted based on design requirements. Manufacturers can modify factors such as dome shape, size, and material thickness to change the response.

A stiffer dome requires more force to press, giving a stronger tactile snap. A softer dome provides a lighter, more subtle feedback. Customizing these factors allows for fine-tuned control over how the switch feels.

Some applications require a strong, sharp click to ensure precise operation. Others may need a softer response for user comfort. By adjusting the design, metal domes can be tailored to specific needs.

Is haptics the same as vibration?

Not exactly. While haptic feedback often involves vibration, it is more than just a simple buzzing sensation. Haptics can create complex patterns of movement, pressure, and force to simulate real-world textures and sensations.

Basic vibration alerts in a smartphone are a form of haptic feedback, but advanced haptics go beyond that. High-end gaming controllers, for instance, can simulate the recoil of a gun or the resistance of different surfaces. This adds depth and realism to the experience.

In contrast, a standard vibration motor simply buzzes at a fixed intensity. It does not provide the nuanced feedback that advanced haptics can achieve. This is why high-end devices invest in refined haptic technology to enhance user interaction.

Conclusion:

Touch feedback is a vital part of modern technology, making interactions more intuitive and enjoyable. Haptic feedback uses vibrations and motion to create immersive experiences, while tactile feedback provides physical resistance and clicks.

Metal domes are a perfect example of tactile feedback in action. Their crisp and responsive feel makes them a preferred choice in critical applications. Their durability and adjustability further enhance their appeal. For high-quality metal dome solutions, contact sales@metal-domes.com