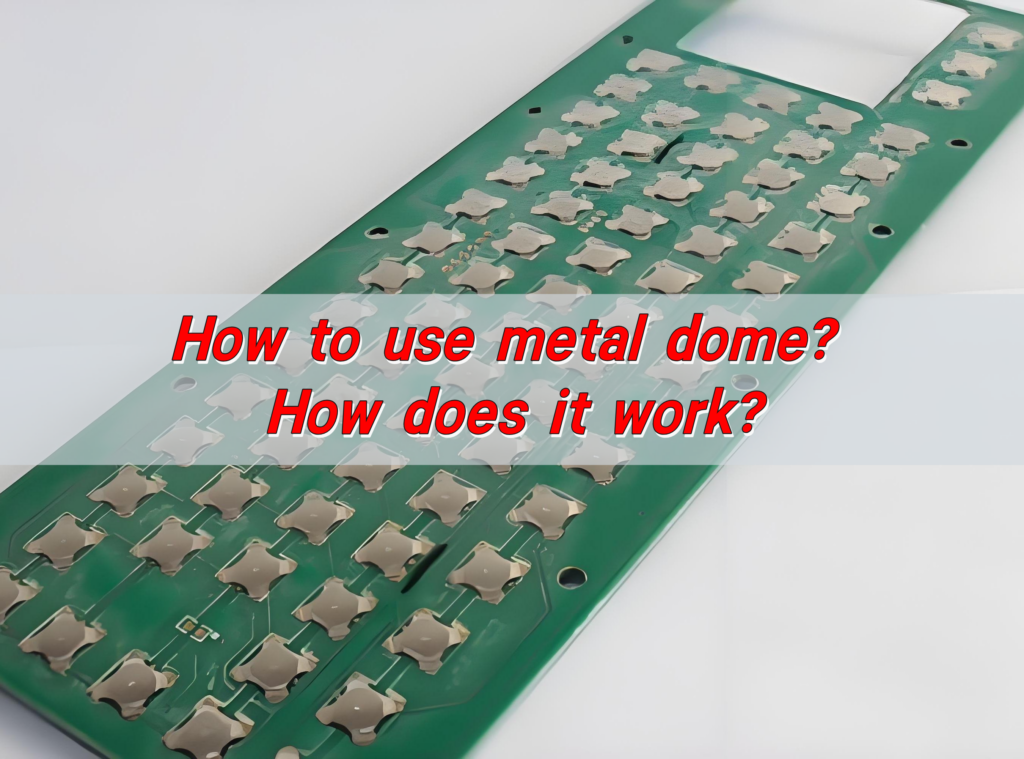

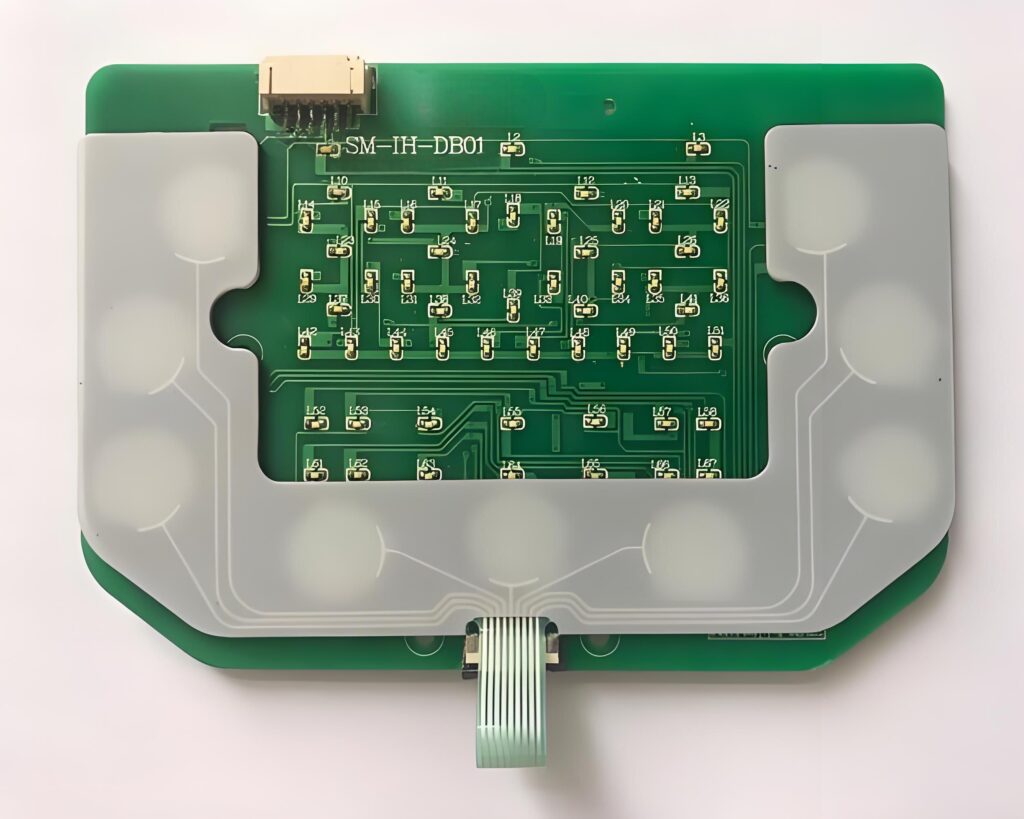

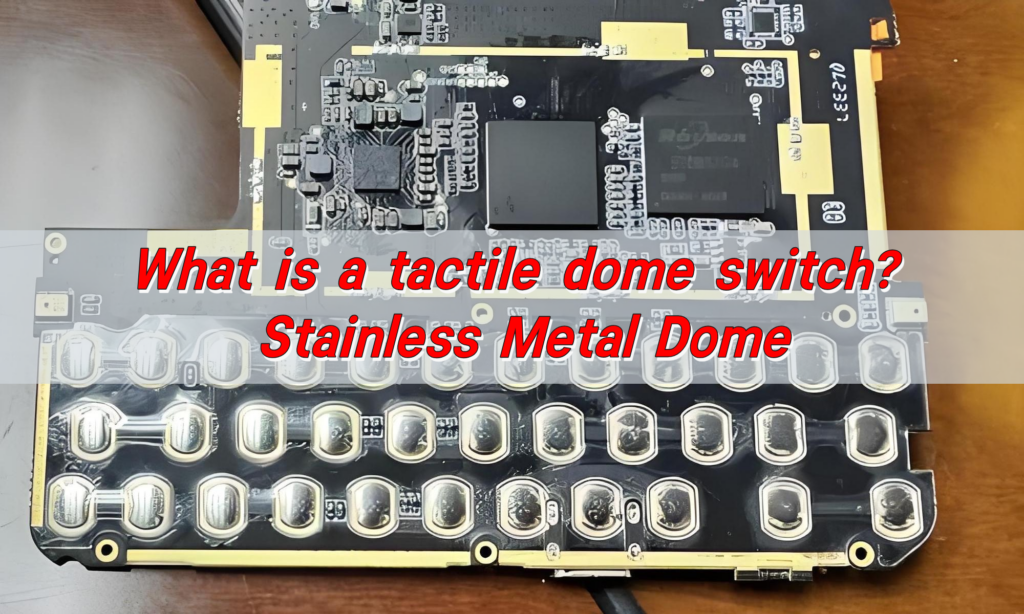

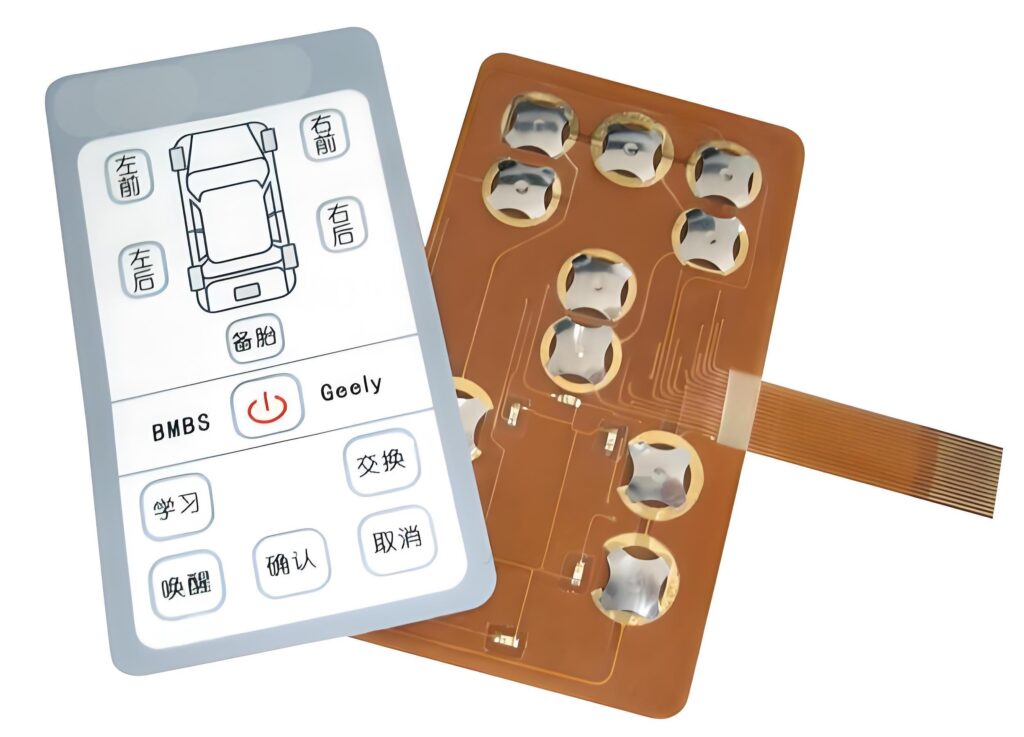

How to use metal dome? Metal dome is an electronic component widely used in touch switches and membrane switches. Its working principle is based on elastic deformation. When the switch is pressed, the metal dome is pressed down by force and contacts the conductive part on the circuit board, forming a circuit conduction; after releasing, the dome returns to its original shape by elasticity, and the circuit is disconnected.

Metal domes are usually made of stainless steel or phosphor bronze, with good elasticity and durability, and provide clear tactile feedback.

How to use metal snap domes?

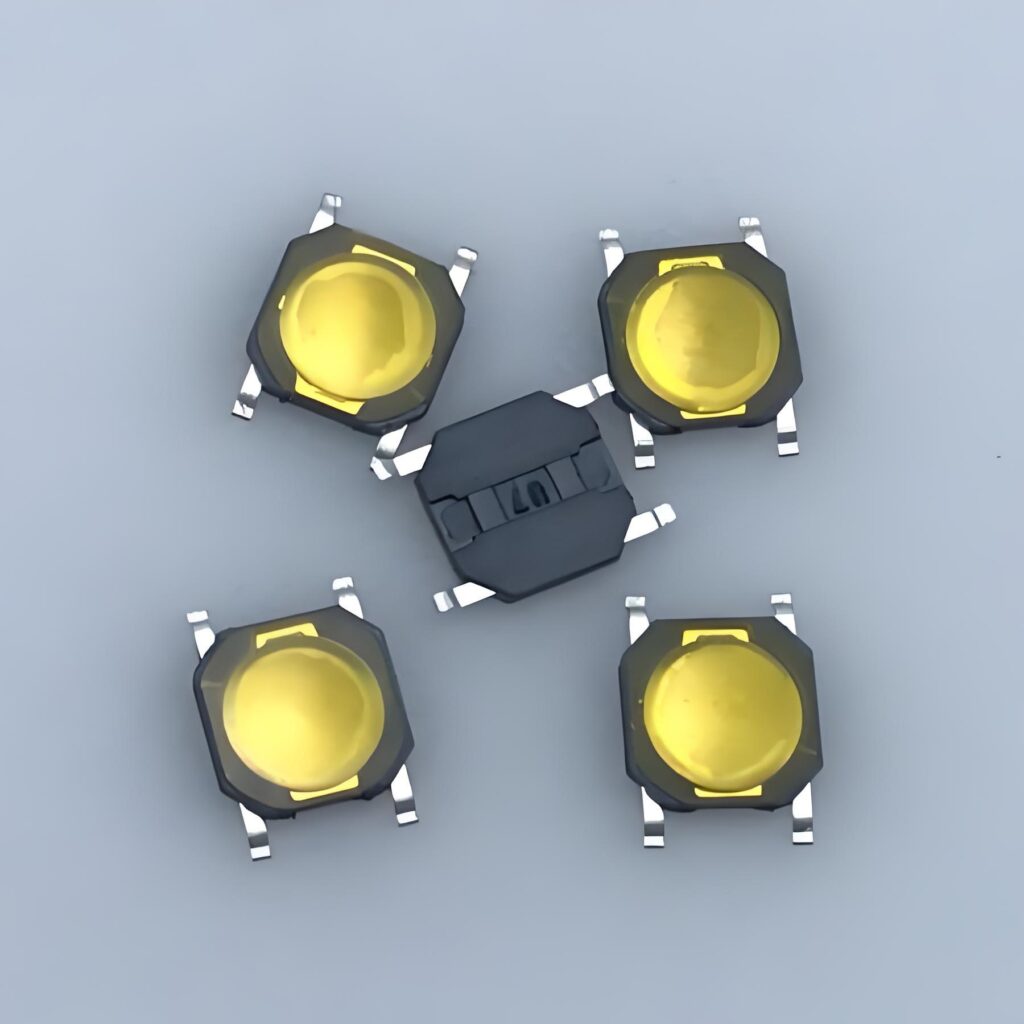

Using metal domes correctly ensures smooth operation and long-lasting performance. These small, curved pieces of metal act as electrical contacts inside keypads. When pressed, they complete a circuit, sending a signal.

To use them effectively:

Choose the Right Dome – Different shapes and forces are available, so selecting the best type for your application is crucial.

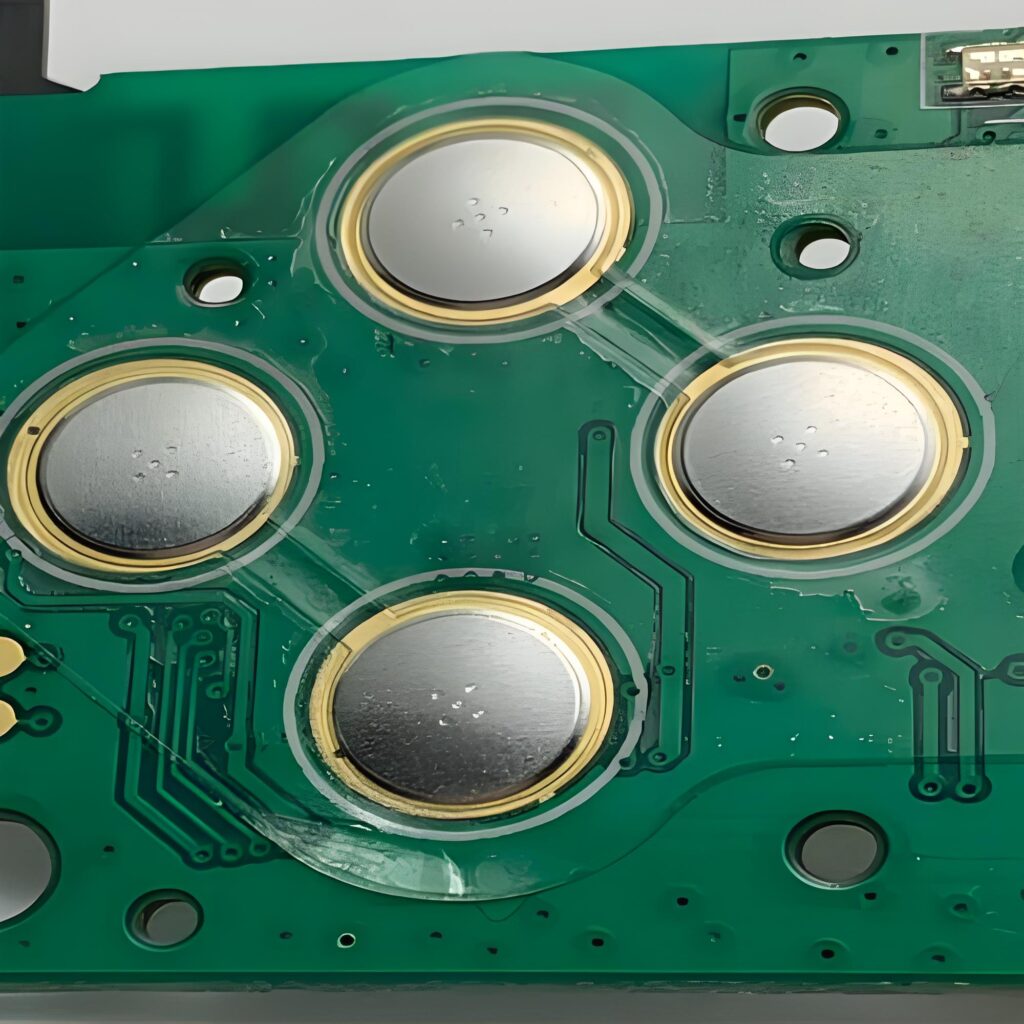

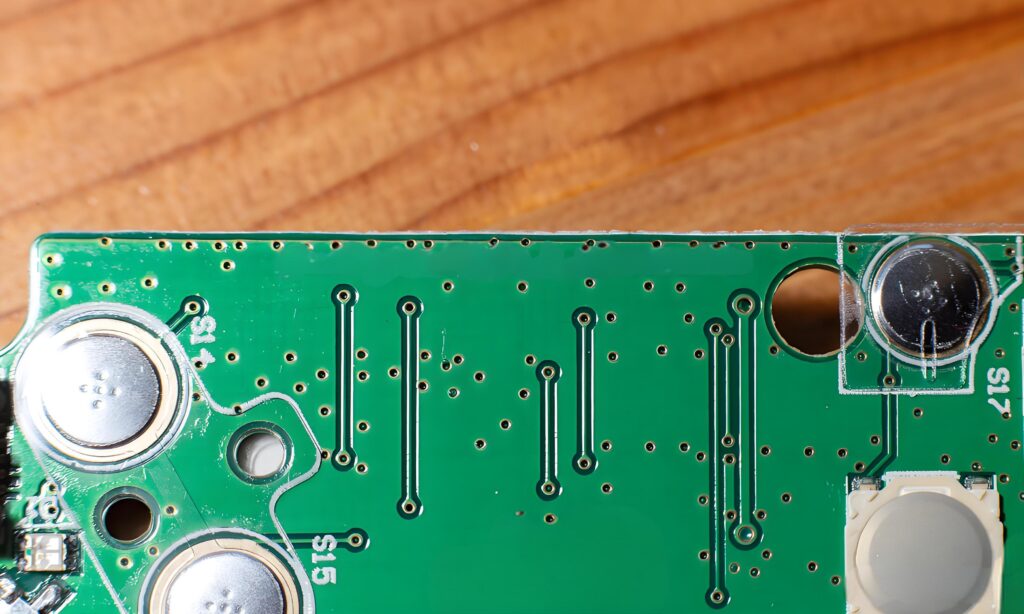

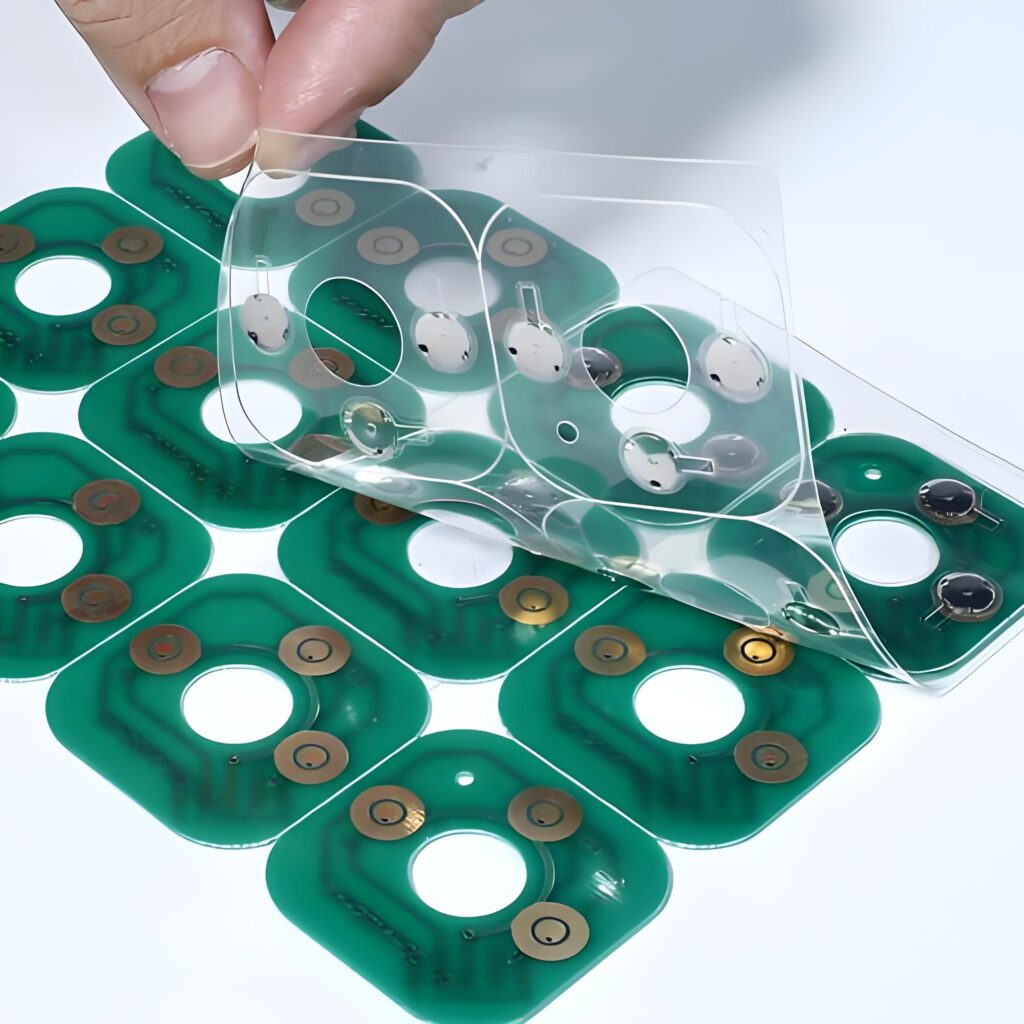

Align with Circuit Board – The dome should be positioned precisely over the PCB’s contact points.

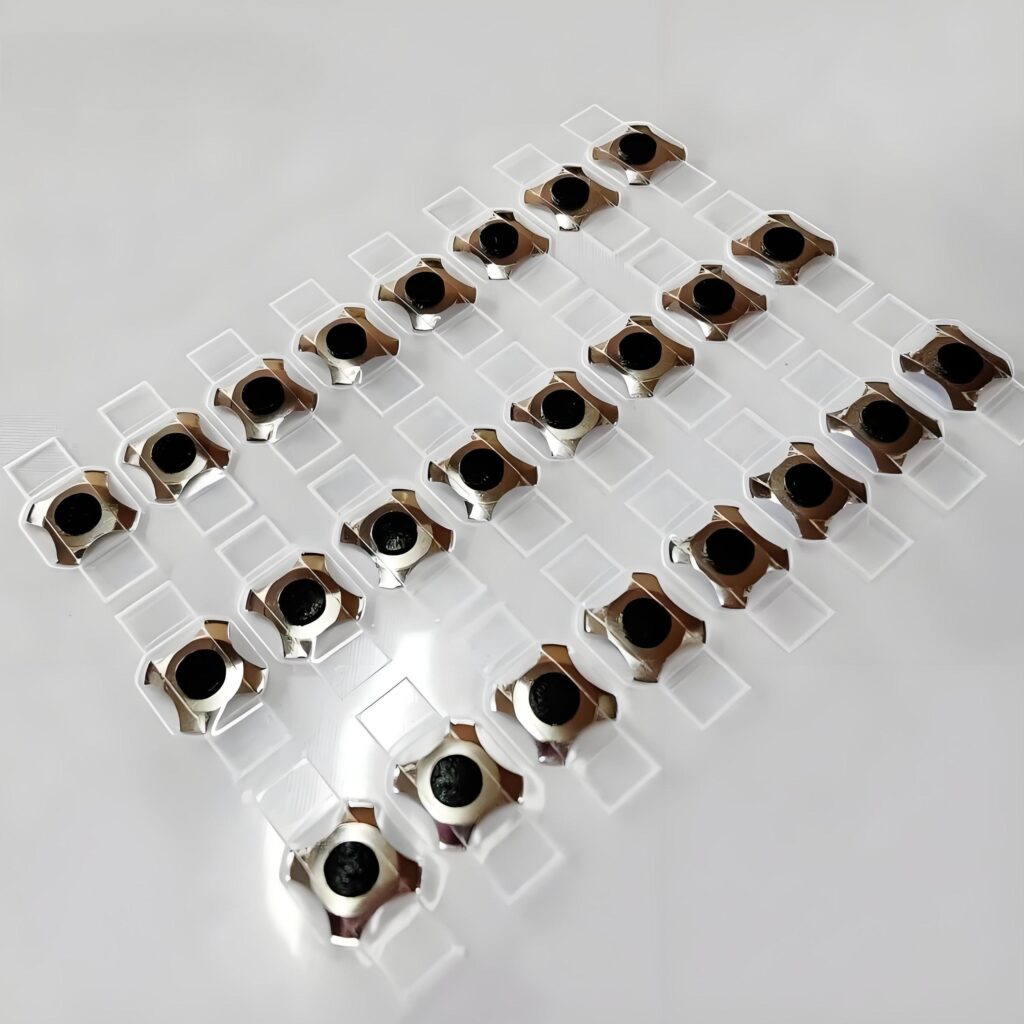

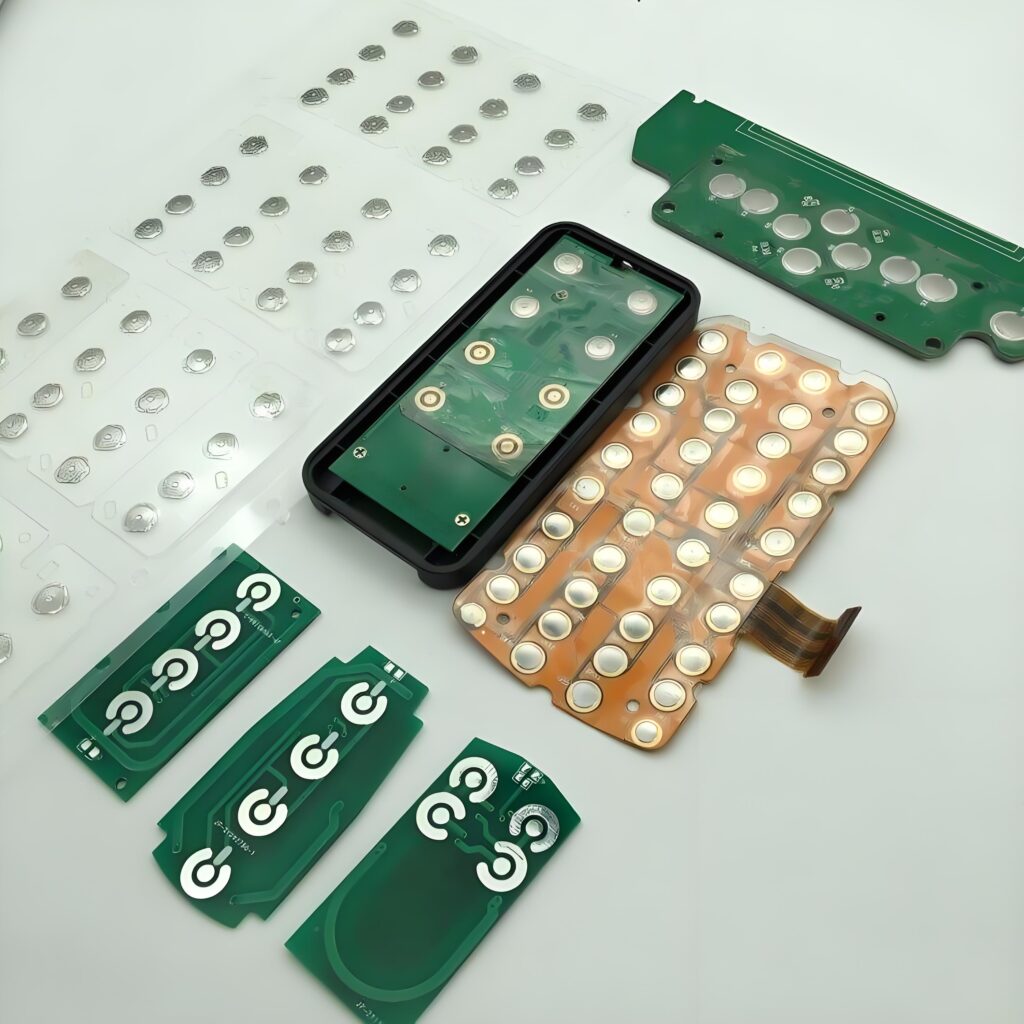

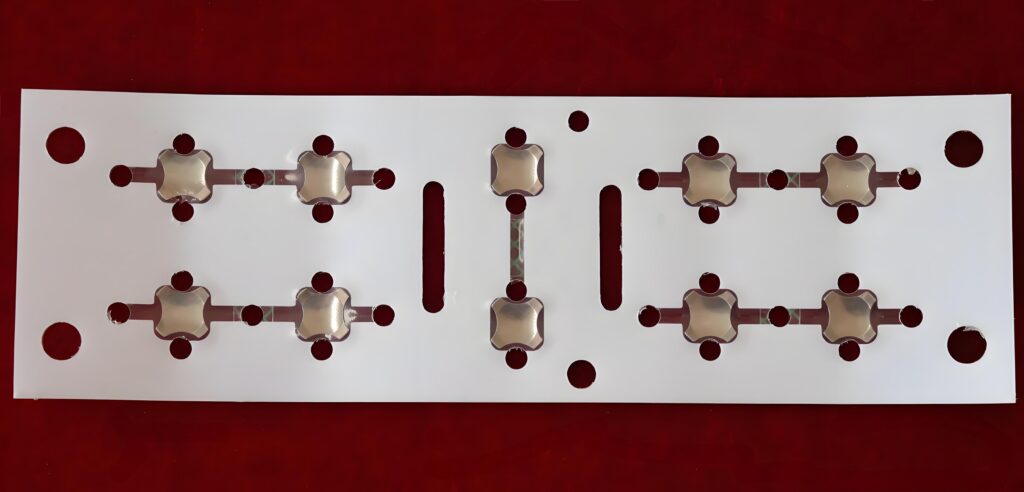

Use Adhesive or Carrier Tape – This helps secure the dome in place, ensuring it functions consistently.

Maintain Cleanliness – Dust and dirt can interfere with conductivity, so keeping the area clean is essential.

Apply Proper Actuation Force – Pressing with the right force ensures a satisfying tactile response and long-lasting durability.

Metal domes are widely used in industries where precision and reliability matter. Their correct placement and maintenance directly affect performance.

How does metal dome work?

Metal domes operate on a simple yet effective principle. They serve as a momentary switch inside a keypad. When pressed, they collapse and make contact with the circuit board, completing an electrical circuit. This sends a signal to the device, triggering the intended function. Once released, the dome returns to its original shape, breaking the connection.

The design ensures a tactile response, giving users a distinct “click” feel. This feedback is critical in many applications, including industrial machinery, consumer electronics, and medical instruments.

Several factors influence how well a metal dome functions:

Dome Shape – Different designs offer varying levels of tactile feedback.

Actuation Force – The pressure required to collapse the dome impacts user experience.

Material Quality – High-quality stainless steel ensures durability and longevity.

A properly designed metal dome enhances user experience, ensuring each press is crisp, reliable, and satisfying.

How do metal domes enhance tactile feedback?

Tactile feedback plays a huge role in usability. Without it, pressing a button feels uncertain. Metal domes provide that critical feedback, making interactions smooth and responsive.

They achieve this by:

- Creating a Noticeable Click – The distinct tactile response reassures users that the button was successfully pressed.

- Providing Consistent Resistance – The force needed to press the button remains uniform, preventing accidental activation.

- Ensuring Quick Recovery – Metal domes snap back instantly, allowing for rapid consecutive presses.

This combination makes them ideal for medical devices, mobile phones, and remote controls, where precise input is essential. When designing a user-friendly device, metal domes are one of the best options available.

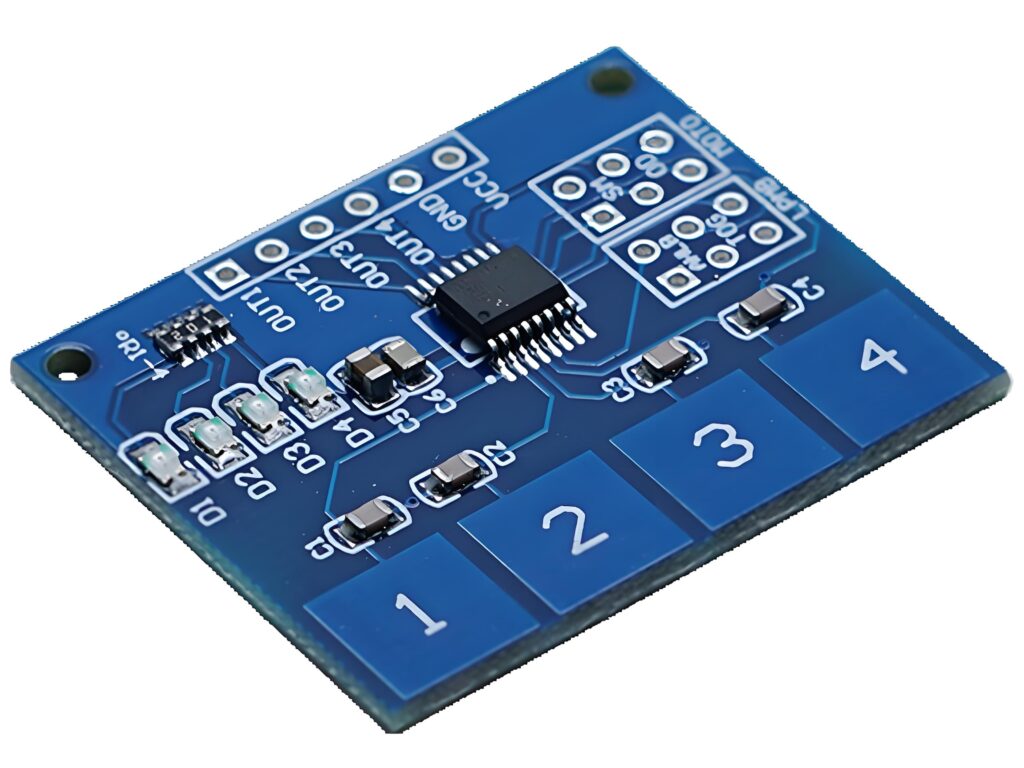

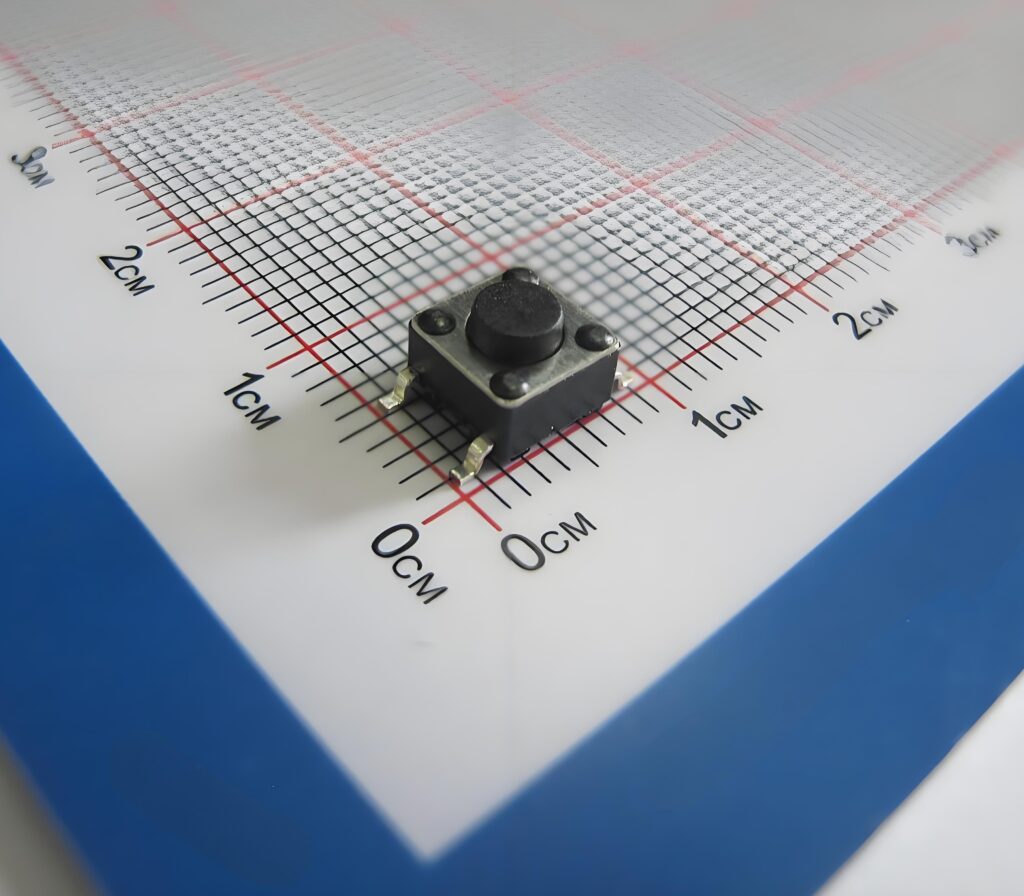

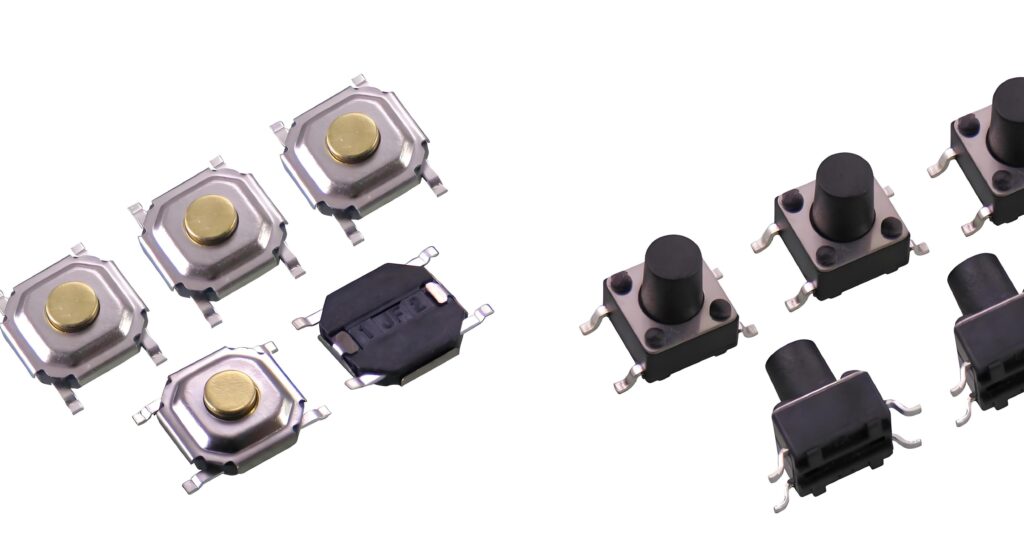

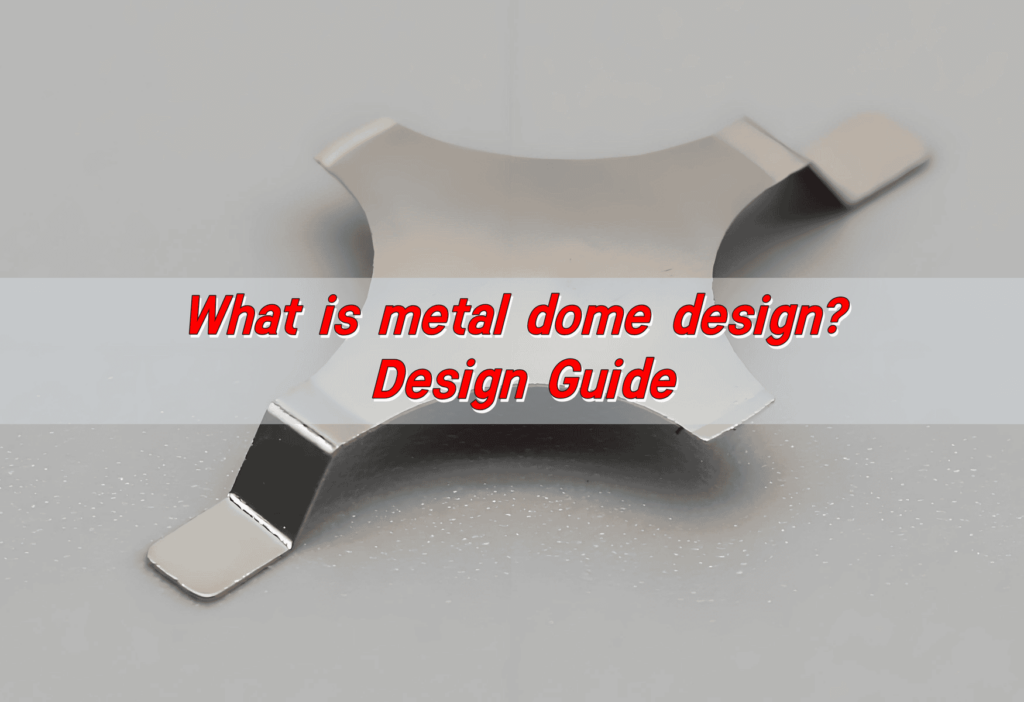

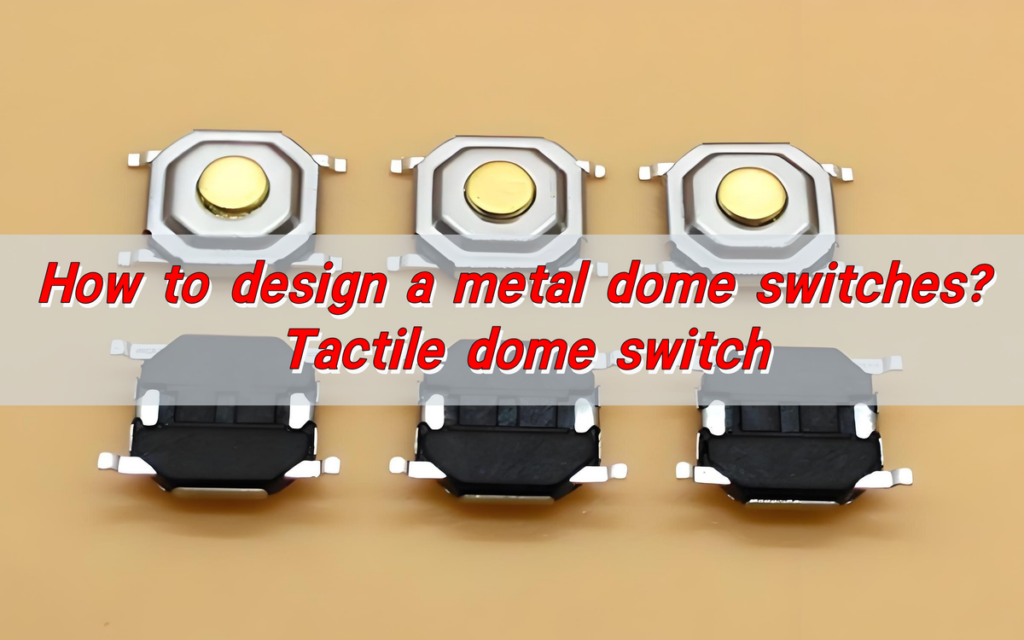

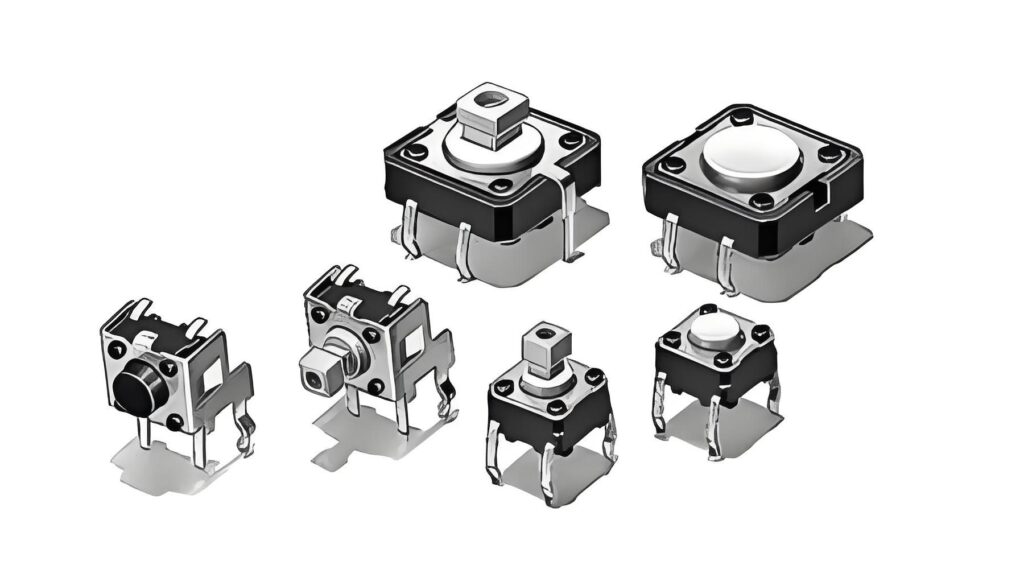

What are the different metal dome shapes?

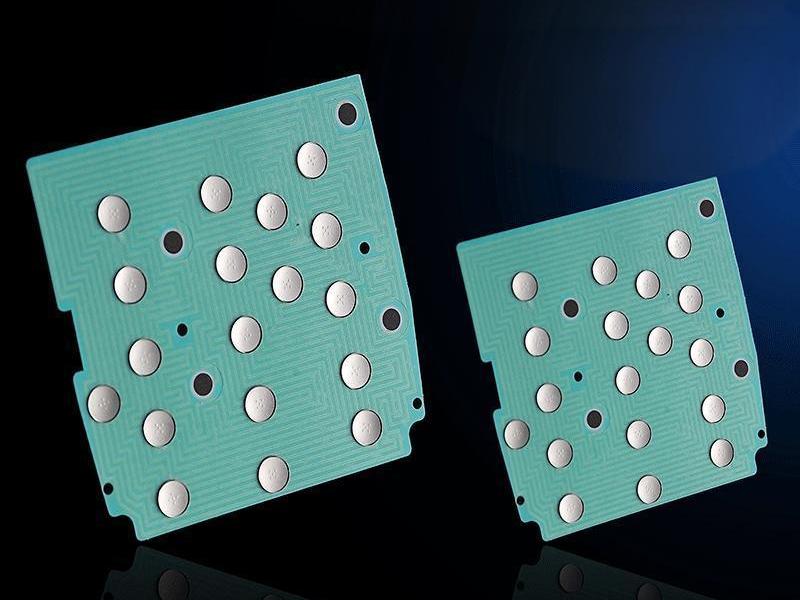

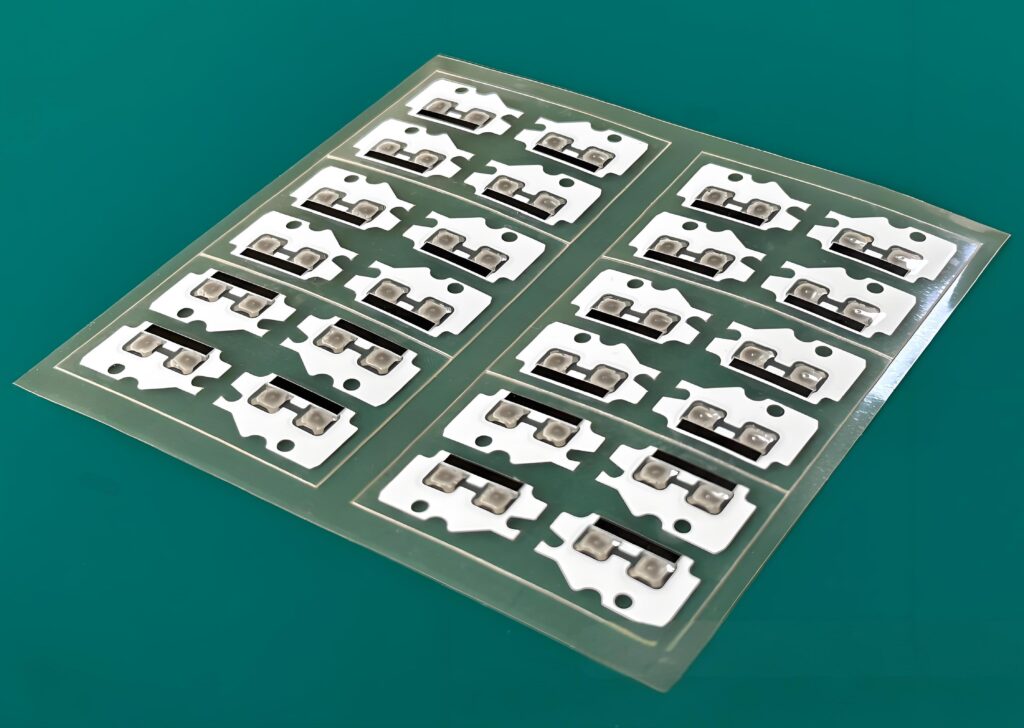

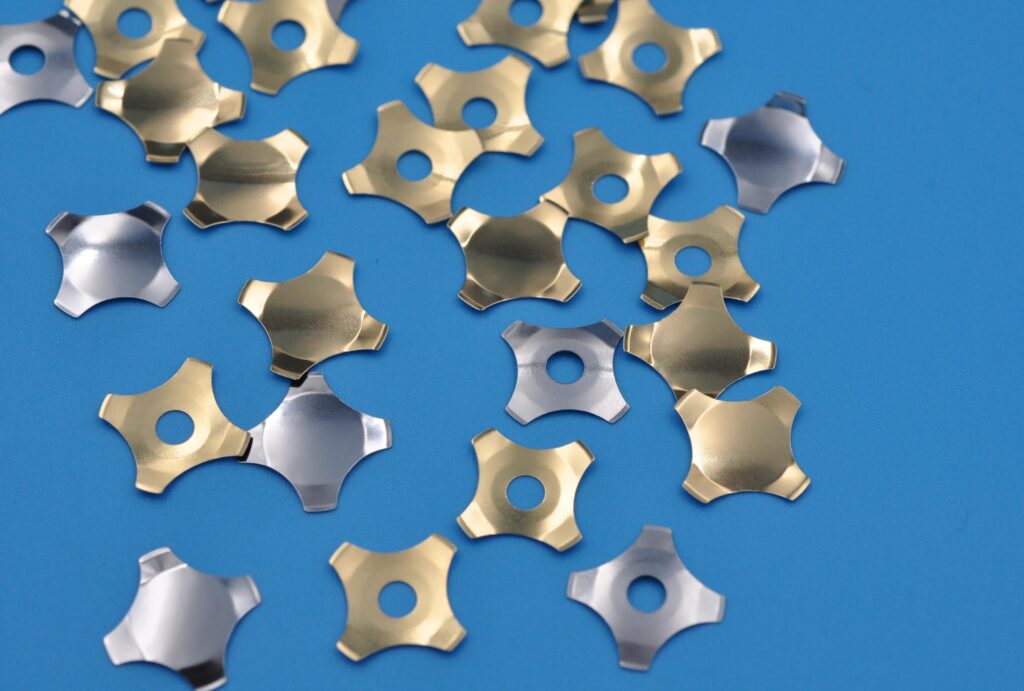

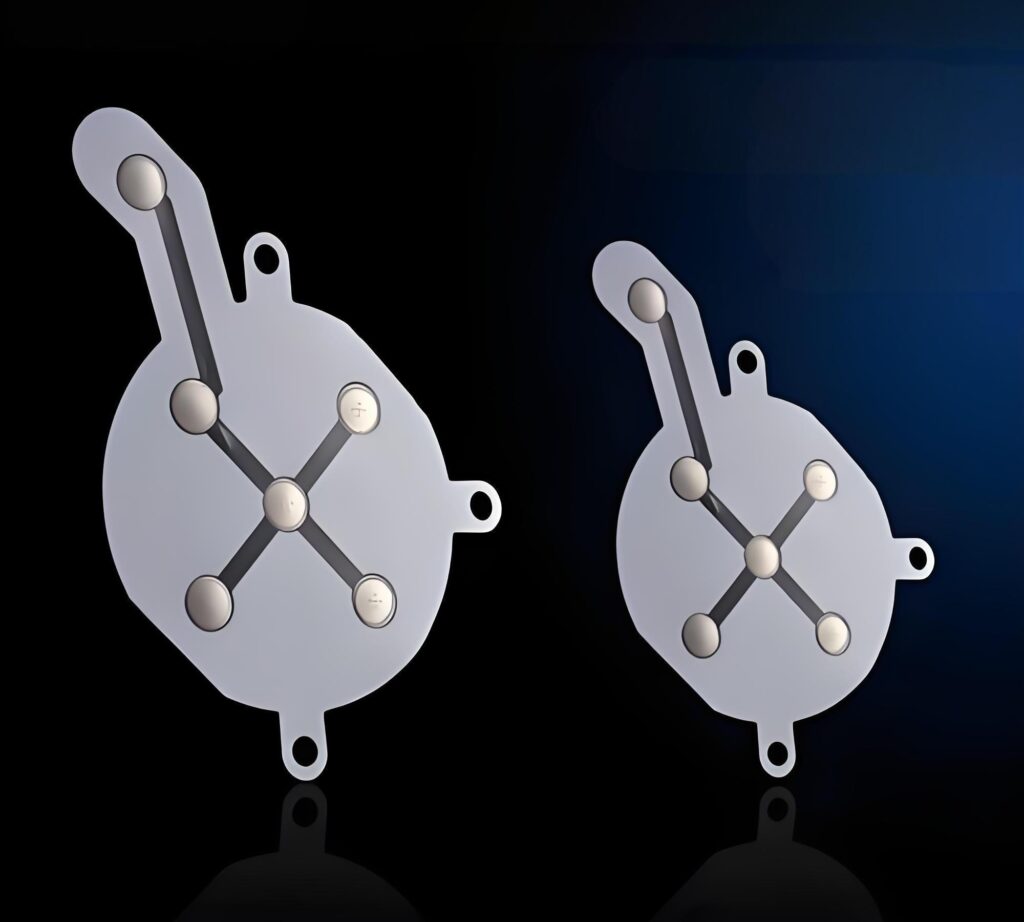

Metal domes come in multiple shapes, each offering unique performance characteristics. The most common types include:

- Four-Legged Domes – These are widely used due to their balanced actuation force and excellent tactile response.

- Triangle Domes – These provide sharper feedback and are often used in applications requiring high precision.

- Round Domes – Known for their smooth feel, these domes are frequently used in consumer electronics.

- Oblong Domes – These are suitable for larger keys and applications requiring extended contact areas.

The right shape depends on your device’s needs. Each shape affects how the dome collapses, how much force is needed, and the type of feedback users experience.

Which metal dome shape is best for your application?

Selecting the right dome shape depends on multiple factors, including user preference, device requirements, and durability needs.

For high-precision applications like medical equipment, triangle domes are a great choice.

For standard consumer electronics, four-legged domes provide a good balance of feel and performance.

For large buttons, oblong domes ensure even pressure distribution.

For soft-touch applications, round domes deliver a smoother experience.

Testing different domes can help determine the best option for your specific needs. The key is to balance tactile feedback with usability.

How to make a metal dome?

Manufacturing metal domes requires precision engineering. The process involves several steps to ensure uniform quality and performance.

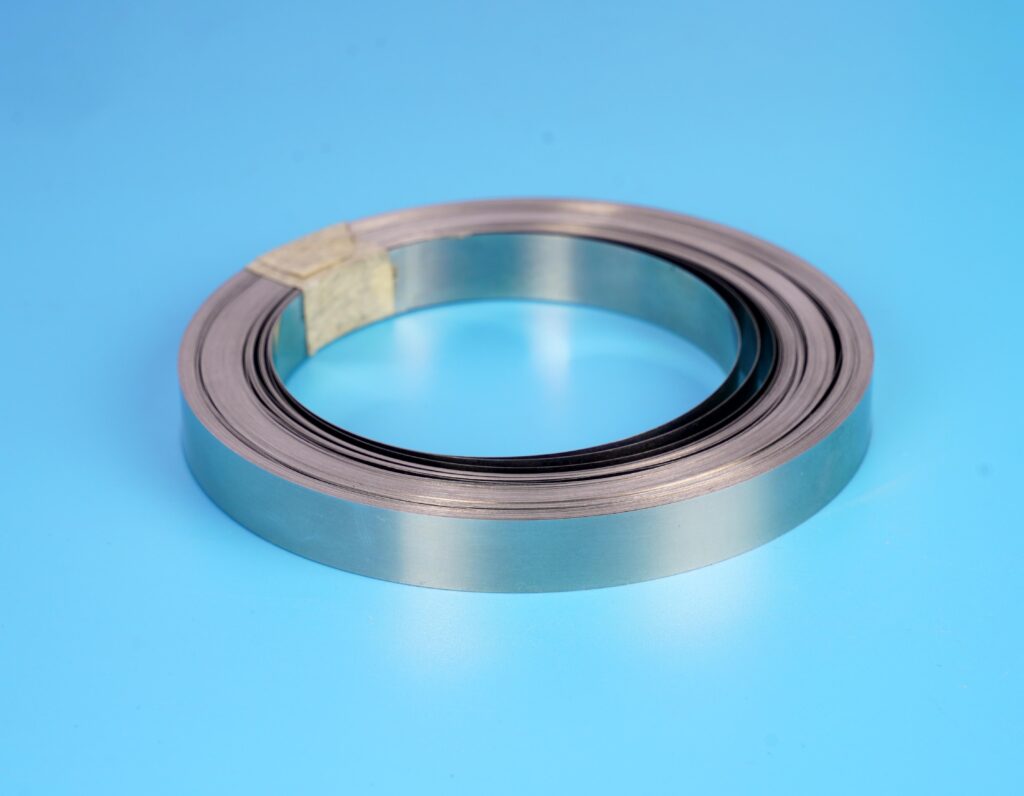

- Material Selection – High-quality stainless steel is commonly used for its durability and flexibility.

- Stamping Process – The metal is cut and shaped using specialized machines to achieve the desired dome shape.

- Heat Treatment – This step strengthens the metal, ensuring it retains its shape after repeated use.

- Surface Finishing – Polishing and plating improve conductivity and resistance to corrosion.

- Quality Inspection – Each dome is tested for consistency in force, shape, and tactile response.

A well-manufactured metal dome will last millions of cycles, making it a cost-effective solution for durable keypads.

How to make a dome from sheet metal?

Creating a dome from sheet metal follows a similar process but requires additional steps:

- Cutting – The sheet metal is cut into precise sections.

- Pressing – A forming press applies pressure to shape the dome.

- Heat Treatment – This strengthens the structure and ensures longevity.

- Finishing – Additional coatings or plating can improve conductivity and durability.

For mass production, manufacturers use automated machinery to maintain consistency. Handmade domes are rare but possible for specialized applications.

What material is the best metal dome?

Choosing the right material affects performance, longevity, and reliability. The most common material is stainless steel, known for its:

High durability – Withstands millions of presses.

Excellent conductivity – Ensures reliable electrical contact.

Corrosion resistance – Prevents wear from environmental exposure.

Other materials, such as nickel-plated steel and gold-plated domes, are used when additional conductivity or resistance is needed. The right material ensures a long-lasting, high-performance component.

Conclusion:

Metal domes are a crucial part of modern electronic devices, providing precise tactile feedback and reliability. Whether in medical devices, consumer electronics, or industrial applications, metal domes play an essential role. For more information or to find the best metal domes for your application, feel free to contact us at sales@metal-domes.com