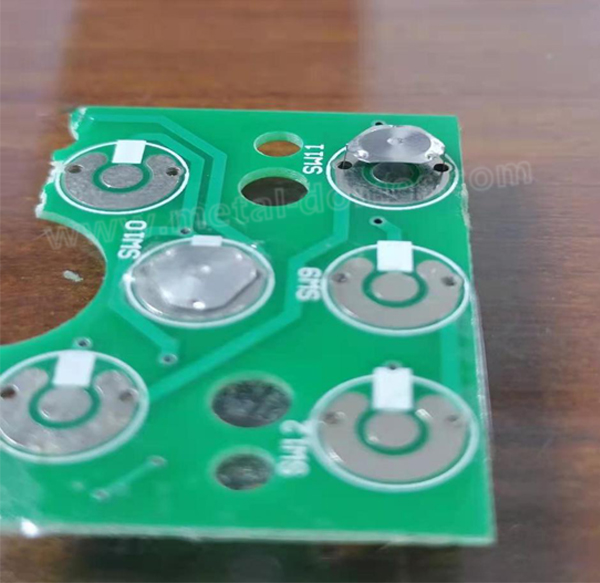

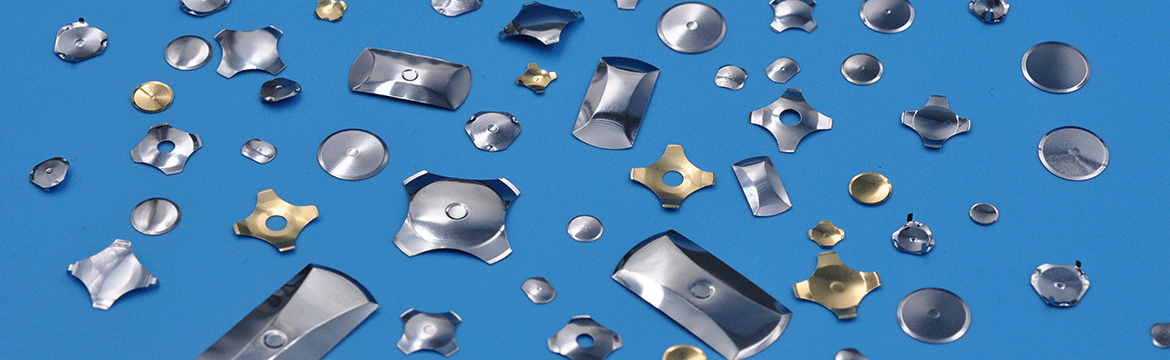

We know there are different assembly methods for metal dome, such as metal dome with legs can insert in PCB’s pin hole to fix, similar like below picture. Most of the dome switch with legs are triangle type. It has several leg specifiication: 0.8*0.8mm, 0.8*1.5mm and 0.8*3.0mm. Usually we can choose the metal dome with the appropriate leg length according to the PCB’S thickness. If you want know further information about how to assemble it please refer to another article “How to assembly triangle series metal dome on PCB”.

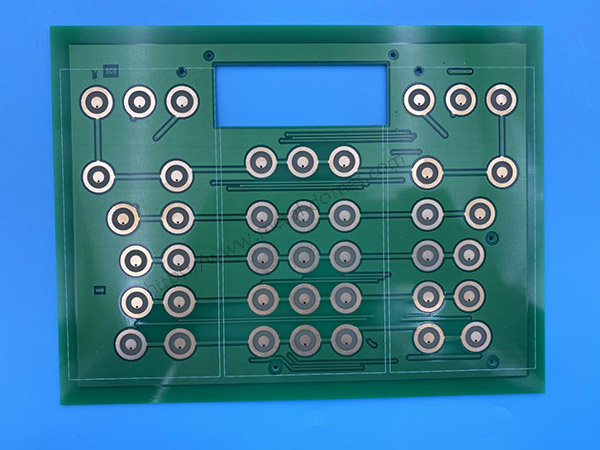

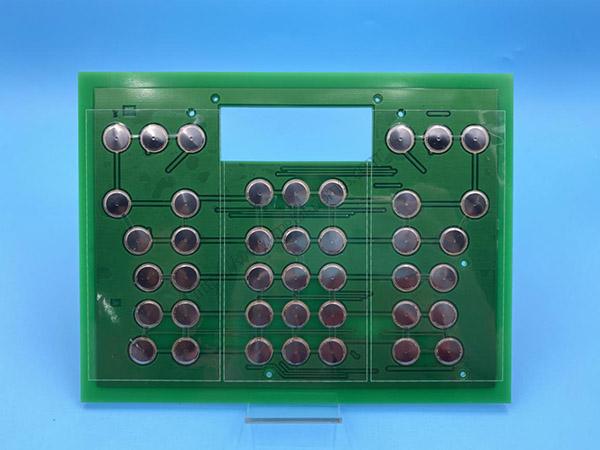

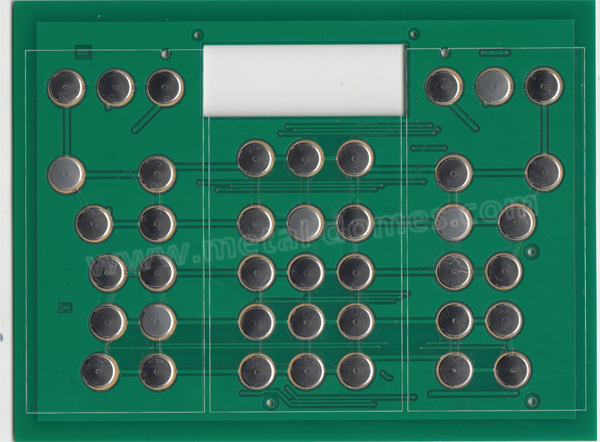

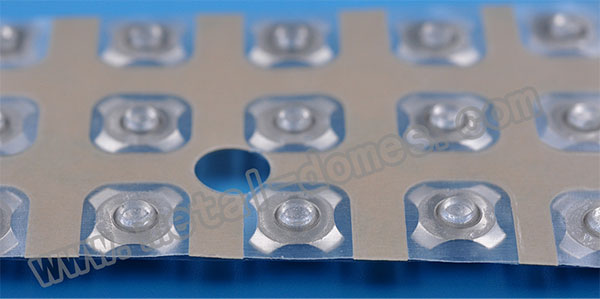

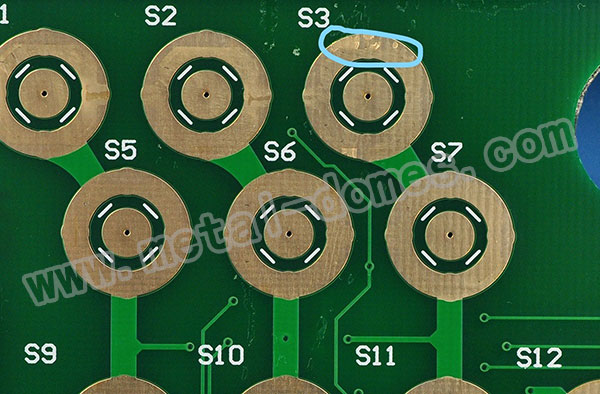

Another method is making metal dome with adhesive tape to be dome array and stick on PCB to conduct with it, we also call it as dome sheet, peel dome. The advantage of making dome array is that its assembly efficiency will be faster than insert one by one, especially when the number of metal domes on a dome array is relatively large, and one dome array can contain different types metal dome but only assemble one time.

Beside those two methods, some clients chose to weld metal dome on PCB board directly, normally we don’t suggest to do it so . Because the metal dome has a little arc with a certain ductility, when we pressing it the metal dome will extend around, if welding it on PCB board, the metal dome can’t extend around when you pressing it, as we pressing for a long time it will easily cause the metal dome to be concave, so it is not recommended to weld metal dome directly.

Best Technology, as the top 5 metal dome & dome array manufacturer in China, we have more than 15 years experience in snap dome, metal dome sheet and tactile membrane switch industrial, our metal dome is equivalent with Snaptron & Nicomatic metal dome,we can always provide you the best solution for your dome switch project. If you have any doubt or inquiry about the snap dome please kindly call us or email us at any time.

-dome-array-8-s.jpg)