Are you wondering how to measure the diameter of triangle metal dome? If you are interesting, let me introduce it brifely.

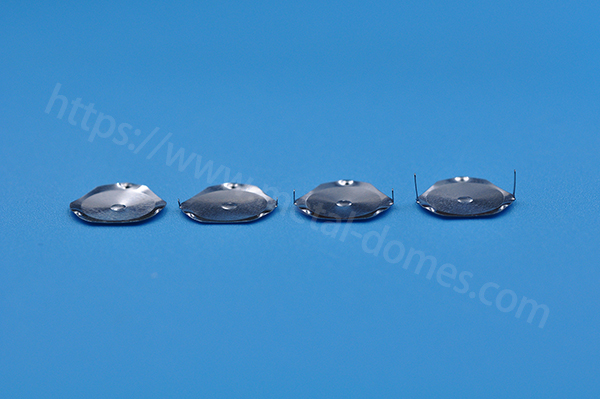

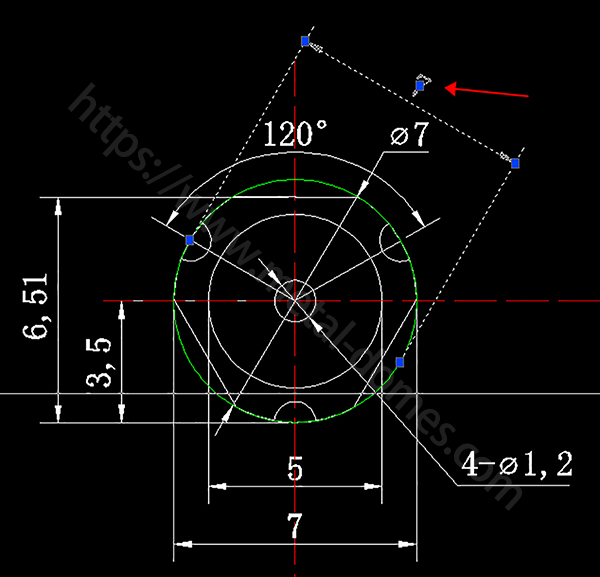

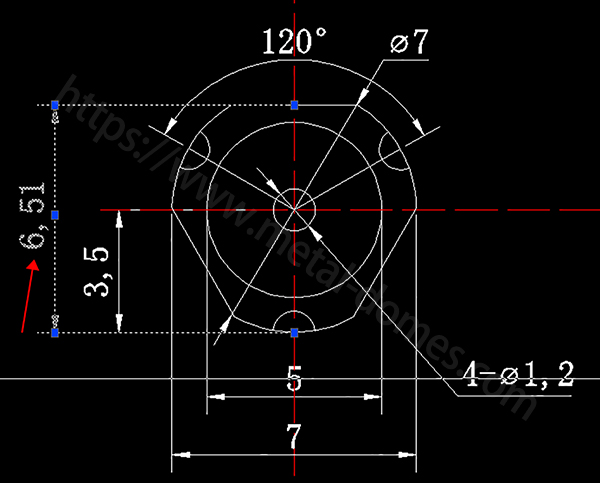

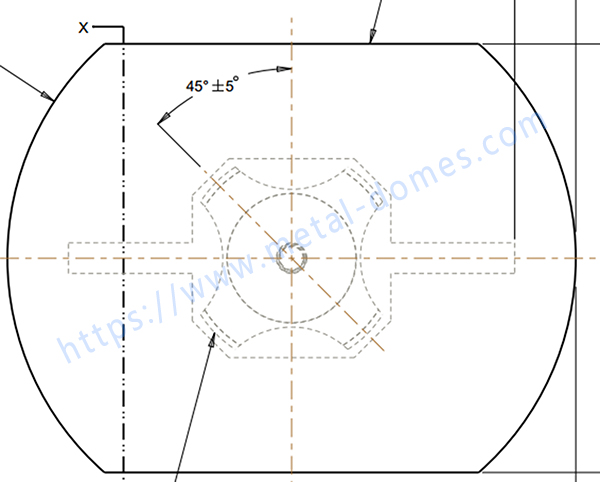

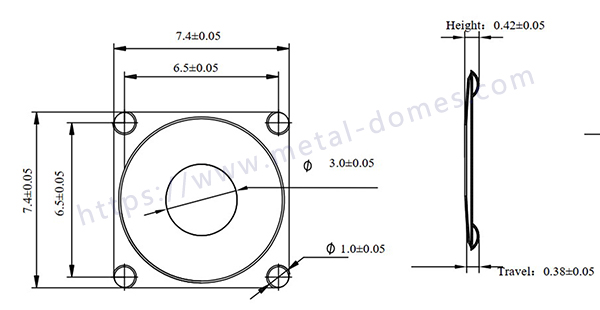

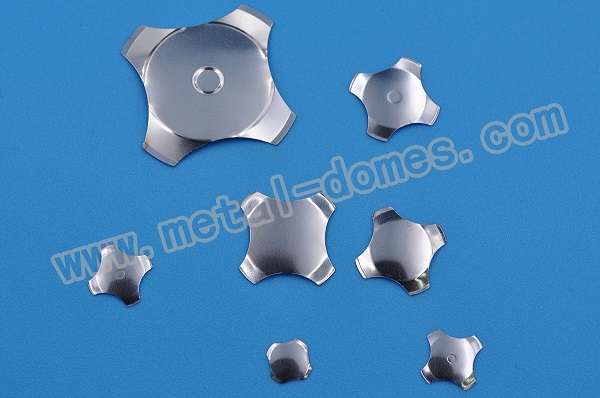

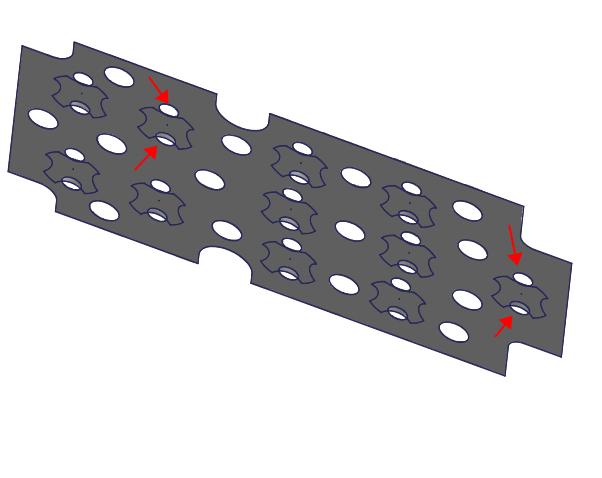

Method one: We know there are three vertices on each sideline of traingle dome, so we can draw a circle along the three vertices and emasure the diameter of circle to get a result, which is diameter of triangle metal dome as well.

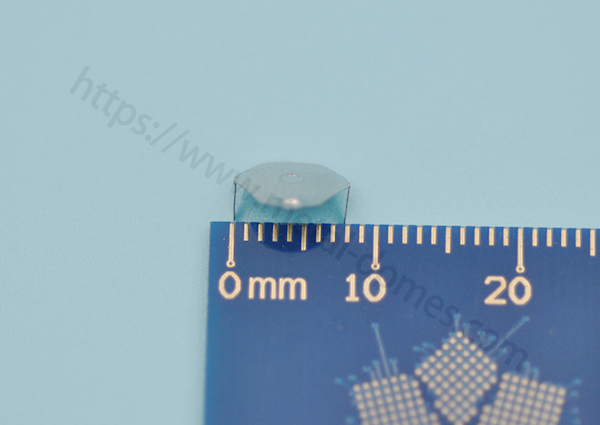

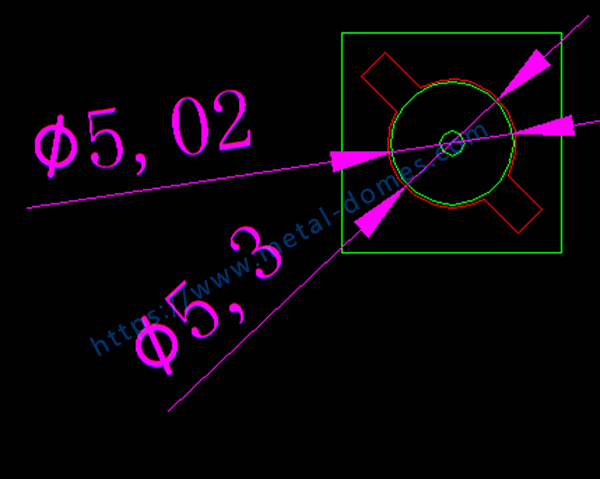

Method two: Measure the distance from one vertice to the oppsite side to get a result and take an integer, this integer is diameter of triangle dome. For example, if you test like this and get a result as 6.51mm, then the diameter of triangle dome is 7mm.

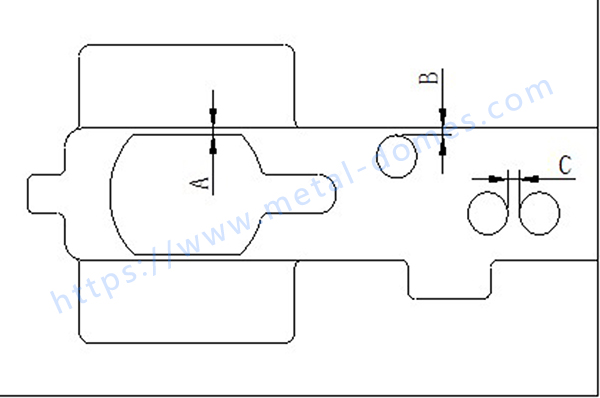

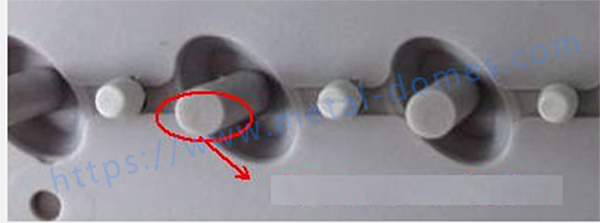

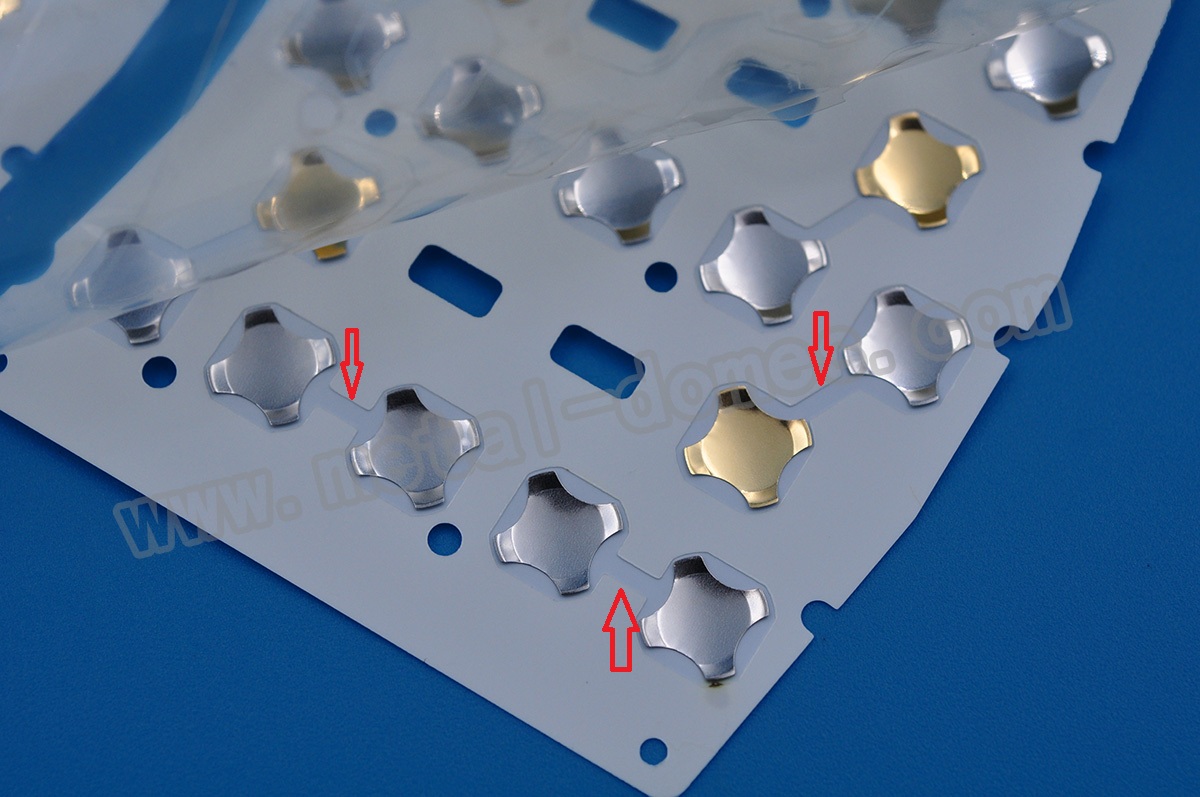

Method three: If the triangle metal dome with legs, we can simple measure the distance between two legs, and this distance is also the diameter of triangle metal dome.

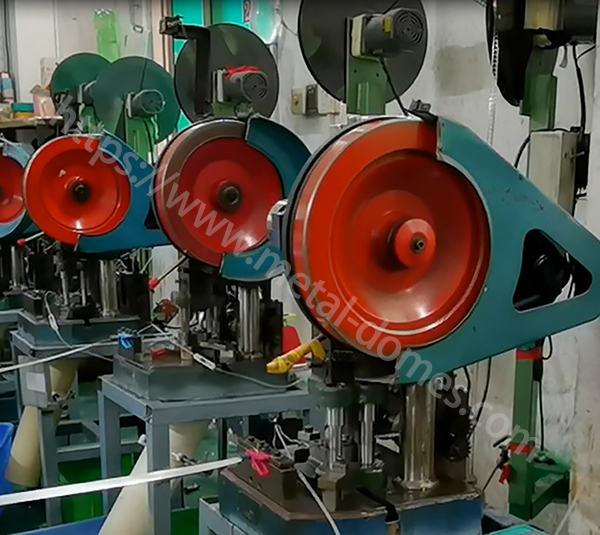

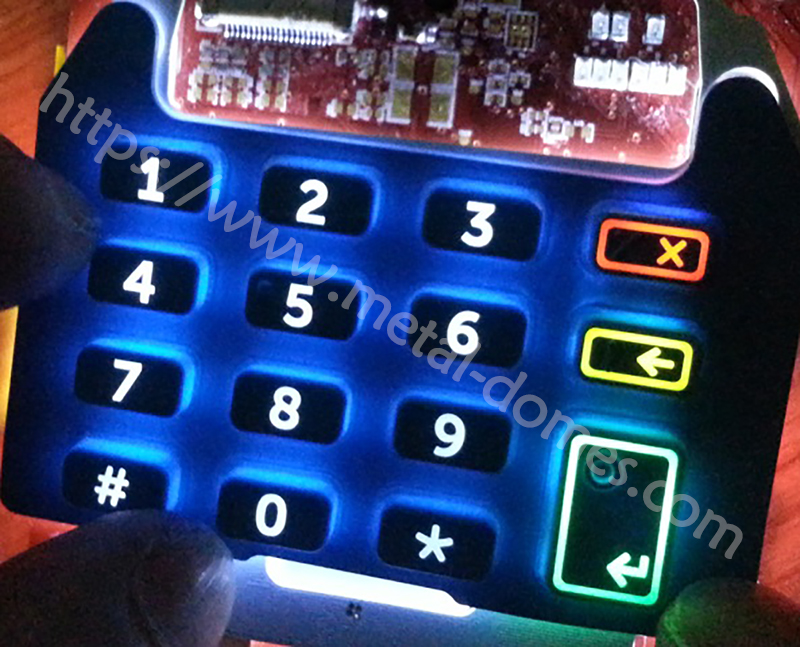

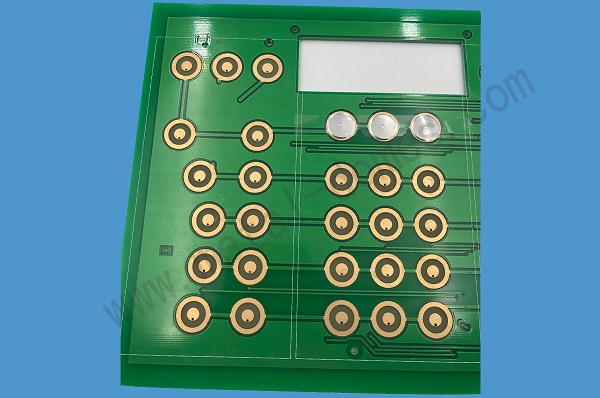

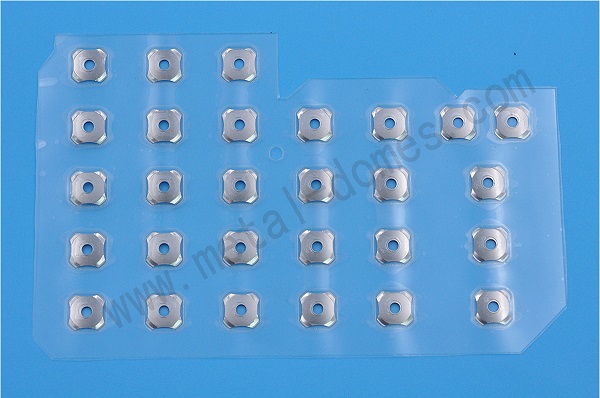

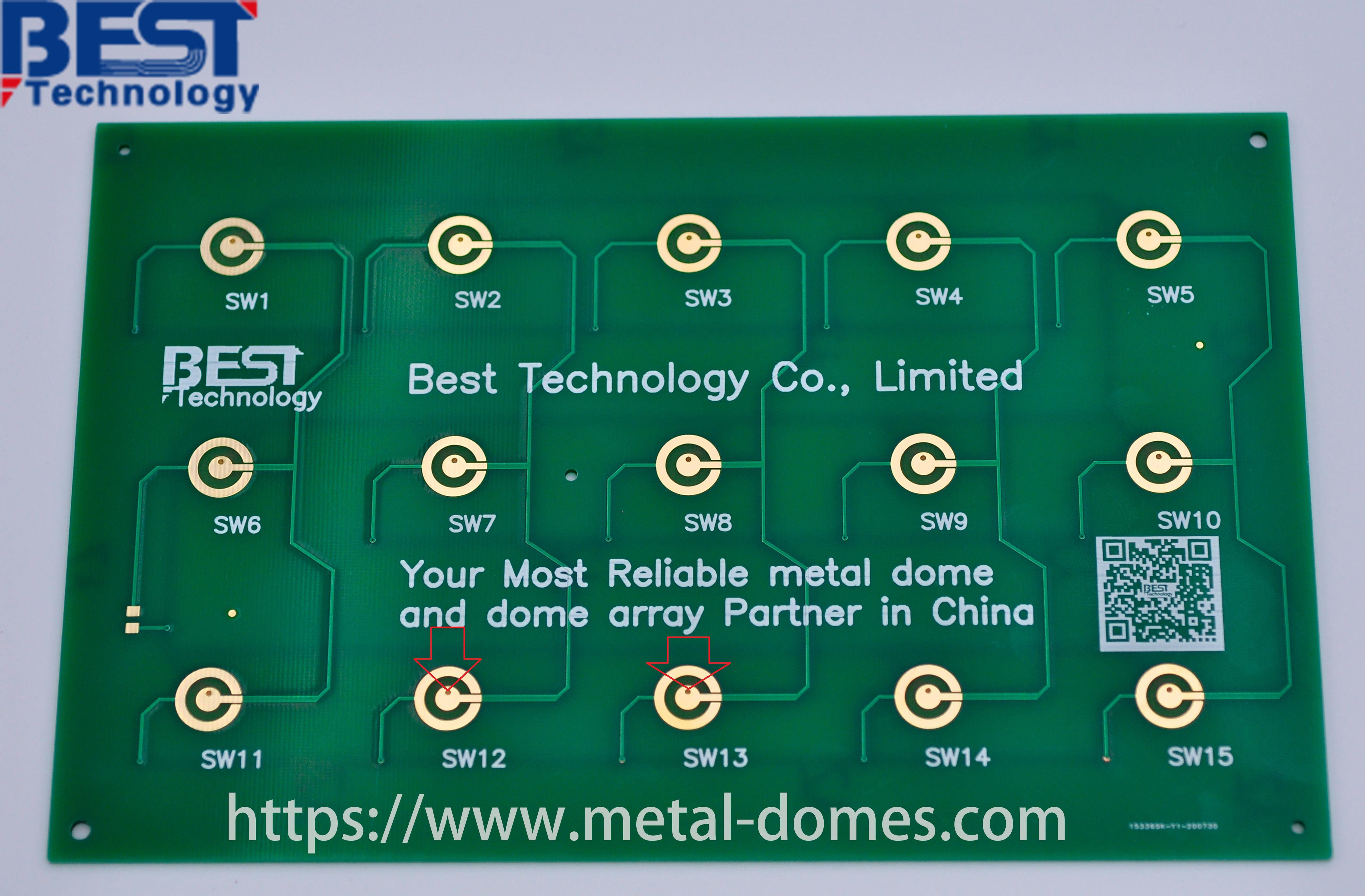

Best Technology, as the top 5 metal dome & dome array manufacturer in China, we have more than 15 years experience in snap dome, metal dome sheet and tactile membrane switch industrial, our metal dome is equivalent with Snaptron & Nicomatic metal dome,we can always provide you the best solution for your dome switch project. If you have any doubt or inquiry about the snap dome please kindly call us or email us at any time.