Although we know LGF (light guide film) can have very good light emitting effect, but the scientific and accuracy of the light emitting effect can’t be detected by using standard instrument, because of its structure characteristics that we need to repeat and debug LGF product samples, so we need to find the factors that influence the LGF emitting effect that can avoid bad product light or uneven.

As shown below, the number keys 1,4, and 7 on the left are significantly darker than the number keys on the right, and the X, arrow character key on the right, is also significantly darker.

But once you find the reason and adjust it, you can turn it into the picture below. The brightness is even and the product looks comfortable.

Why the light emitting effect is so different with same product?

If the light conduction effect of the product is not good, it will bring the following problems:

1. The visual effect of the product is affected, such as stray light, astigmatism, light leakage, ghost and other problems, which will make customers feel that the quality of the product is not good, and thus affect the customer’s experience of using the product.

2. It will increase the cost of product return, scrapping and maintenance, and seriously affect the company’s reputation.

3. Products gradually lose competitiveness and lose customers and markets.

4. The light guide of the product is not good, which not only affects the appearance, but also makes it inconvenient for customers to use, and naturally, they will not buy again

When we have a product with poor light guide effect, we usually think to change the whole product design or increase the qty of LED lights, such as adding LED lights in the dark area of the product. Although this method can solve the problem, it is time-consuming and energy consuming, and increases the cost, but it may not get the desired effect. So, we still need to understand why light is bad, then could solve the fundamental problem.

The reasons of poor light emitting effect of products:

1, It is related to the raw material differences between material PC and TPU of light guide film (LGF). When we choose raw materials, it is not the thinner or thicker with better, the thinner PC material will be with the greater light loss, but the feeling will be better, the thicker material will be with the smaller light loss, but the feeling will be poor, so we need to choose the right material according to the product.

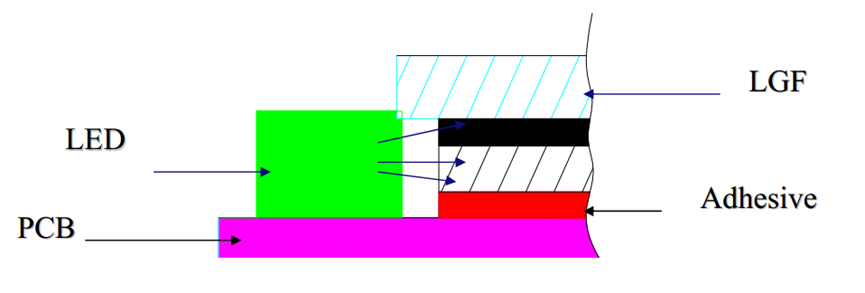

2, The poor assembly of LGF and LED leads to poor light guide effect. Mainly due to the following reasons:

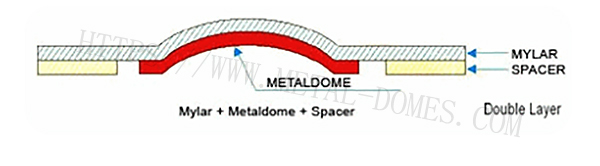

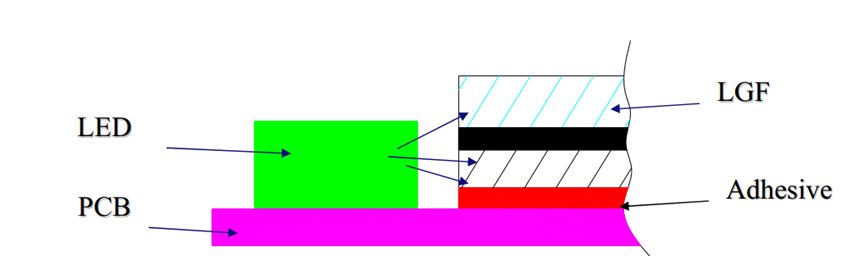

A: As structure in below, the thickness of LGF exceeds the height of LED, the light emitted by LED cannot shine on LGF well, so the light emitting effect is poor. The result may be there is light in the near light area, but no light at all in the far light area.

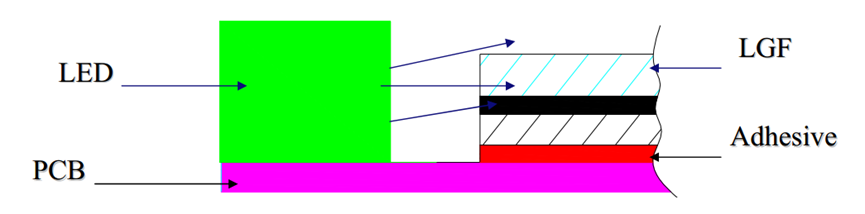

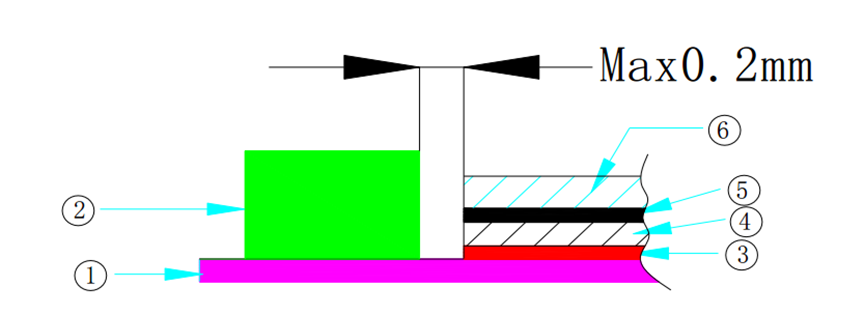

B: As structure in below, the distance between LGF and LED is greater than 0.2mm, and the LED light energy cannot shine on LGF well, the light emitting effect is poor. The phenomenon is that there may be a light in the near light area, but the light effect in the far light area is very poor.

The distance between normal LGF and LED should not exceed 0.2mm, as shown below:

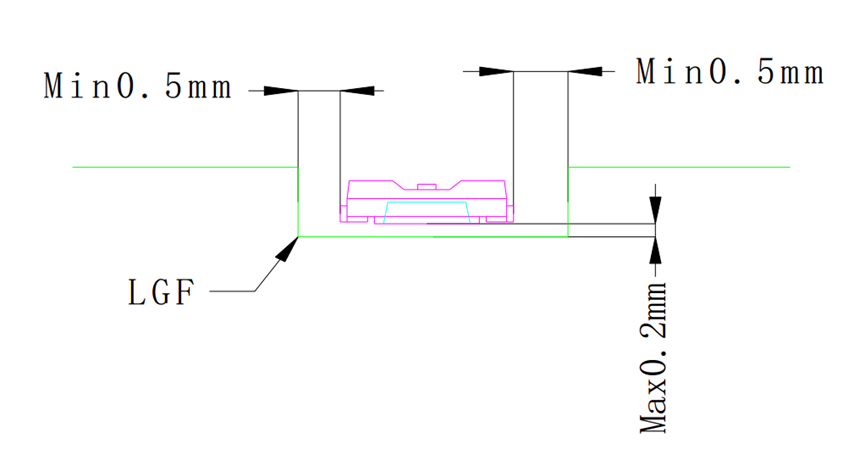

C: As structure below, part of LGF has covered the LED, which has the worst light emitting effect, because the light cannot reach the light guide film.

D: As structure below, the fitting distance between LED and LGF should not exceed 0.2mm, otherwise there will be a dark area in the side far light area.

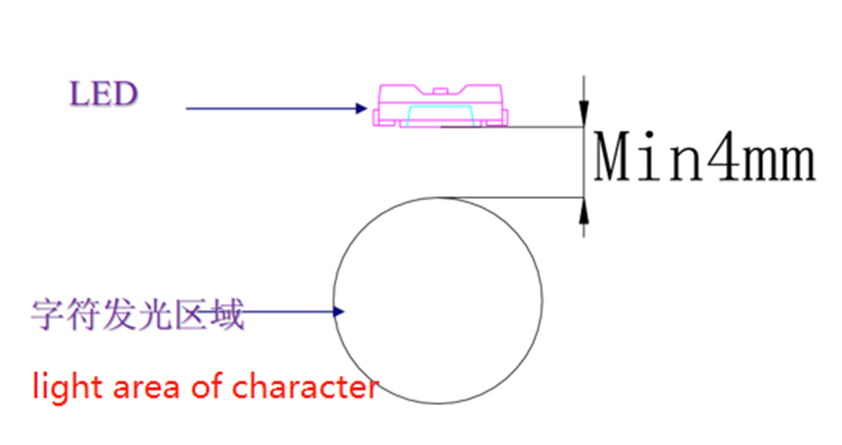

E: As photo below, the vertical distance between the LED and the light area of character should be kept at least 4mm, so could ensure that there is no bright spot near the light area.

F: As photo below, the number of LED should be determined according to the size and height of the product, and the luminance of LED should be at least 1000MCD.

G: The choice of LED location, according to the keypad style, will be evenly distributed in the center of DOME or light guide membrane (top light) or not distributed in the center (side light). If the LED location is not well selected, the light guide effect will also be affected.

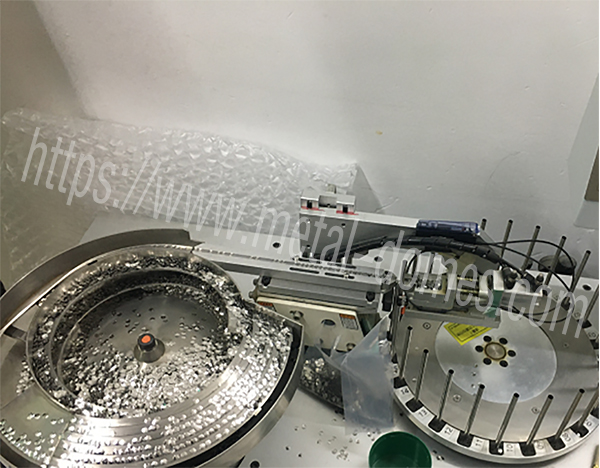

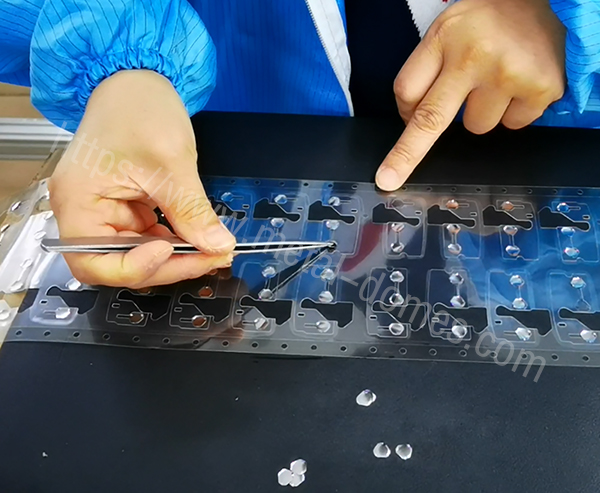

3, The different production process of LGF also greatly affects its light emitting effect. The quality of the production process is the last key factor that affects the light emitting effect of LGF, and the most important is the light emitting dot placement on the light medium material. Light from the LED is scattered from the front of the light guide plate through these micro structured dots.

After read above, we believe you should have a direction for how to solve the problem of poor light guide effect of products, this is the purpose that we write this article, hope it could help you a lot.

Some customers may not use LGF to guide light, even though you should also have an understanding about LGF. If there are products that need to guide light, you can try to use LGF to save cost.

And in the next section, I will introduce the production process of LGF and the testing equipment needed; how different that the light conduction effect of products with LGF and without LGF, etc.

Welcome to contact us if you have any questions about LGF.