As technology continues to advance, the need for reliable and efficient input devices has become a top priority in all walks of life. Of the many options available, dome arrays have become a popular choice for many applications. Whether in consumer electronics, automotive controls, or industrial machinery, dome arrays offer a unique combination of features that make them a versatile and sensitive choice for designers and engineers.

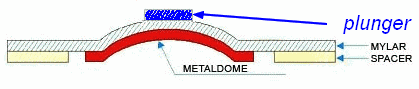

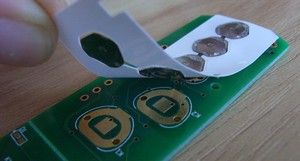

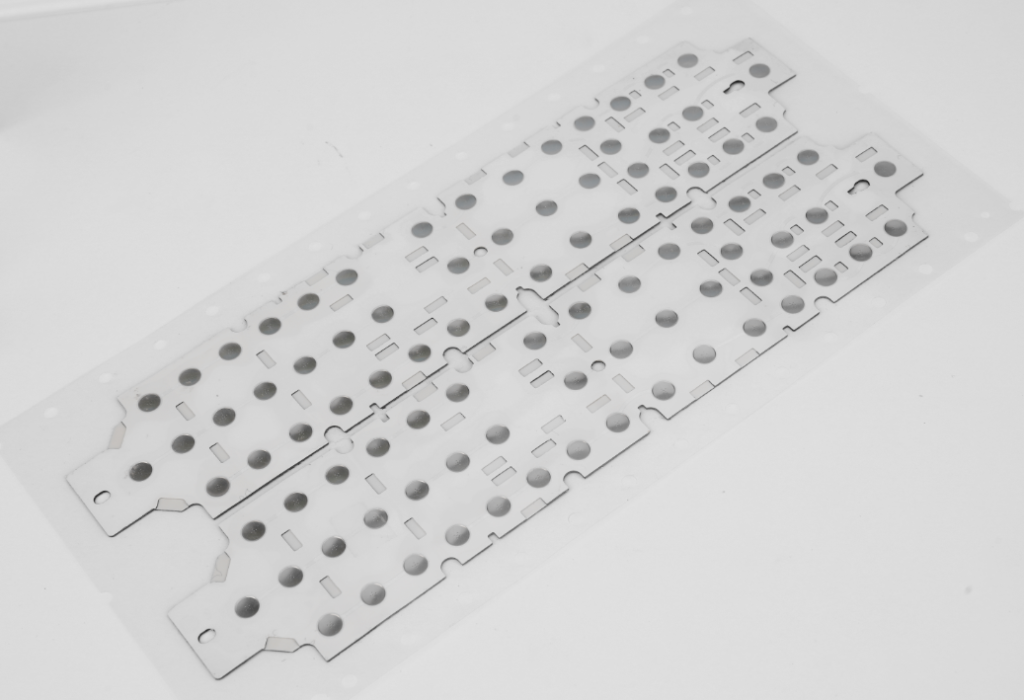

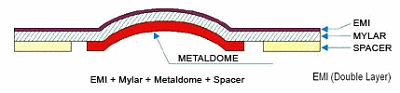

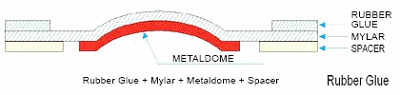

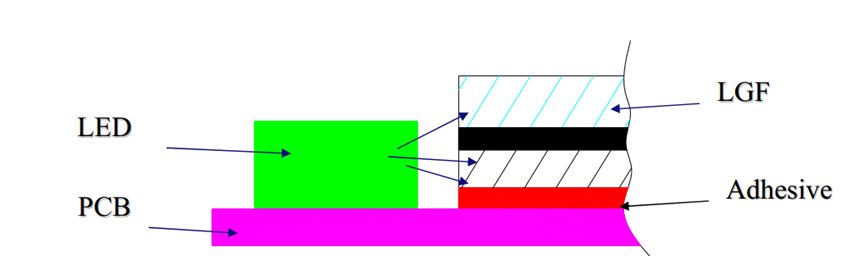

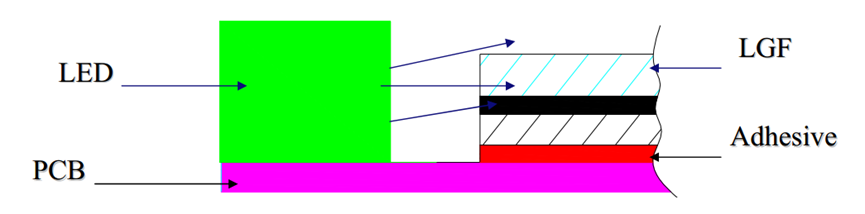

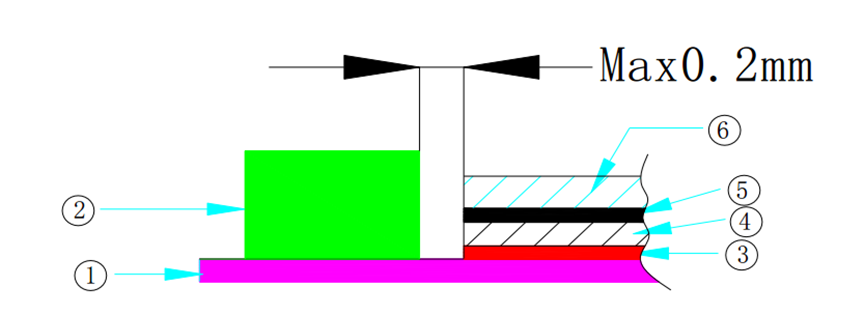

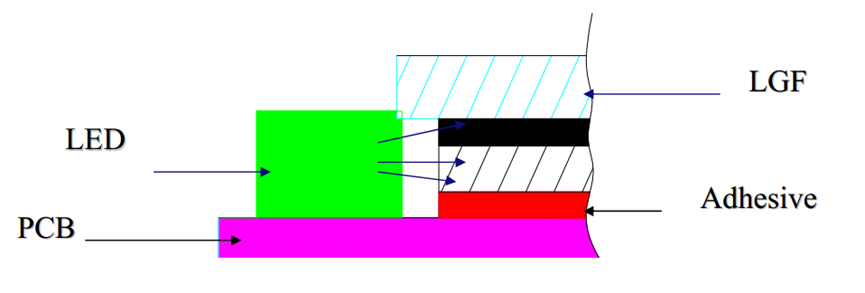

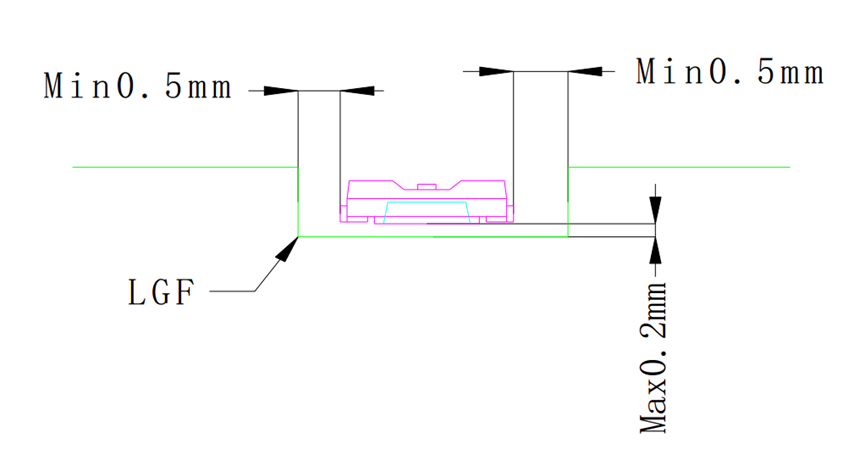

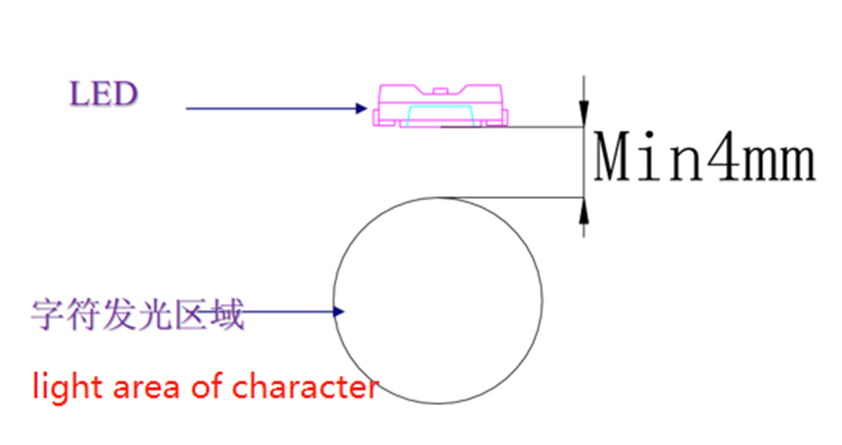

At the heart of the dome array is a small metal dome that serves as the key element. These domes are made of high quality stainless steel for durability and longevity. The dome is mounted on a printed circuit board (PCB), usually coated with a tactile or conductive material. When the switch is pressed, the dome collapses, creating tactile feedback and completing a circuit that sends a signal to the device.

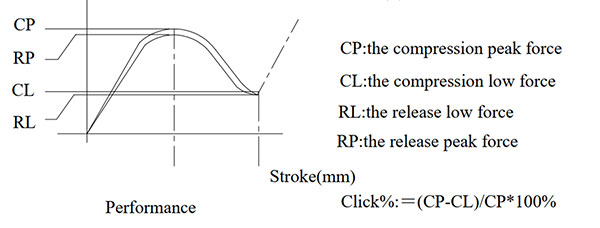

One of the key features of dome arrays is their tactile feedback. When the dome collapses, it provides a distinct ‘click’ or ‘snap’, reassuring the user that their input has been registered. This feedback is essential in applications that require precise input, such as keyboards, game controllers, or medical devices. It helps users enter data or control functions quickly and accurately.

Another distinguishing feature of dome arrays is their responsiveness. Due to its simple yet effective design, the dome array provides fast and reliable actuation with short travel distances and low force requirements. This makes them ideal for applications where speed and precision are critical, such as industrial control panels or automotive buttons. The dome array can also be customized with different actuation forces and travel distances to meet specific requirements, providing design flexibility.

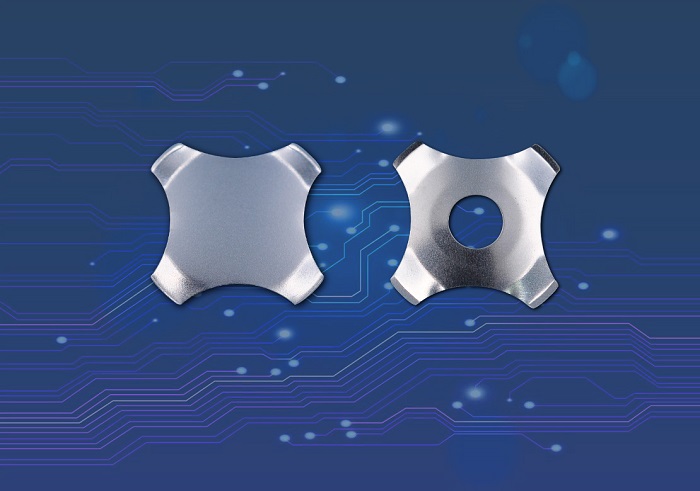

Furthermore, the dome array is extremely durable and resistant to environmental elements, the stainless steel material used in the dome ensures excellent wear and tear resistance. The dome array will go through the dome life test before being sold, and the dome can rebound normally after tens of thousands of repeated pressings, which makes the dome array suitable for a wide range of applications, including outdoor equipment that requires strict hygiene standards, automotive control and medical equipment.

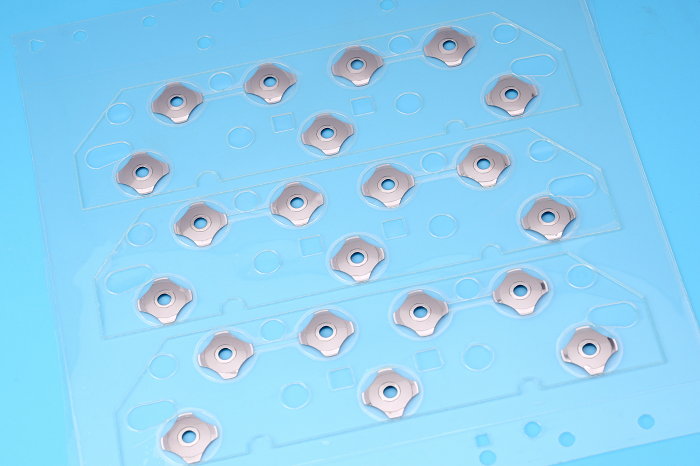

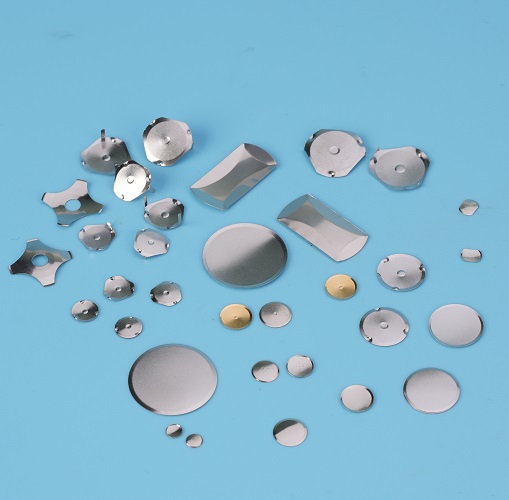

Additionally, the dome array offers design versatility. They come in a variety of shapes, sizes and configurations allowing for flexibility in product design. dome arrays offer a unique combination of features that make them a popular choice for many applications. Their tactile feedback, responsiveness, durability and design versatility make them ideal for a wide range of industries. As technology continues to advance, dome array is likely to remain a major player in the field of input devices, providing reliable and efficient solutions for a variety of applications.

In short, Best Technology adopts advanced production technology and high-quality managers and operators to produce reliable products for us. Best has been committed to the quality control of metal dome, ensuring that the products received by customers are of high quality, so as to satisfy customers. If you are interested in our products after reading this article, you can contact us for consultation, or you can send us an email to sales@metal-domes.com.