Now there are many customers who don’t know much about metal domes when they buy them, they only know that the cheaper the better. But this is actually one of the biggest misunderstandings. When purchasing a metal dome, you should consider many aspects, from material selection and manufacturing precision to contact force, driving life and surface protection, and at the same time choose the most suitable metal according to the quality of the metal dome.

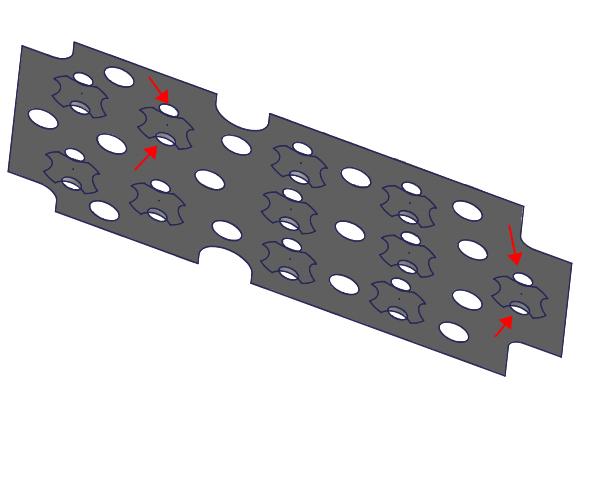

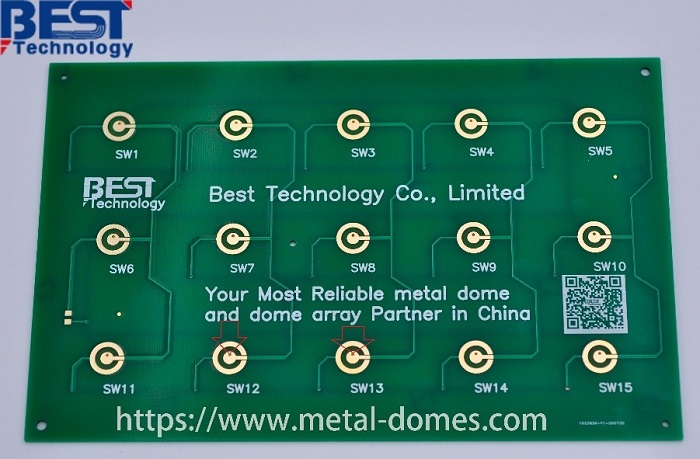

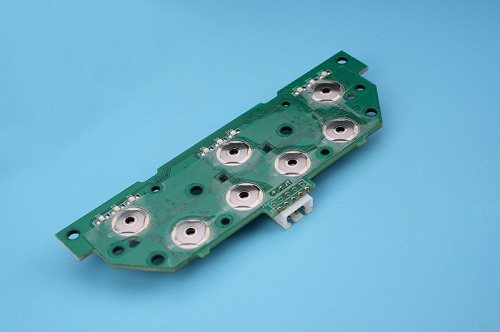

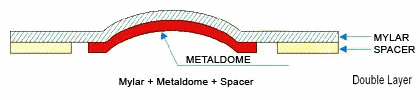

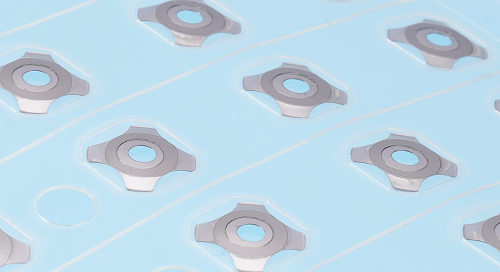

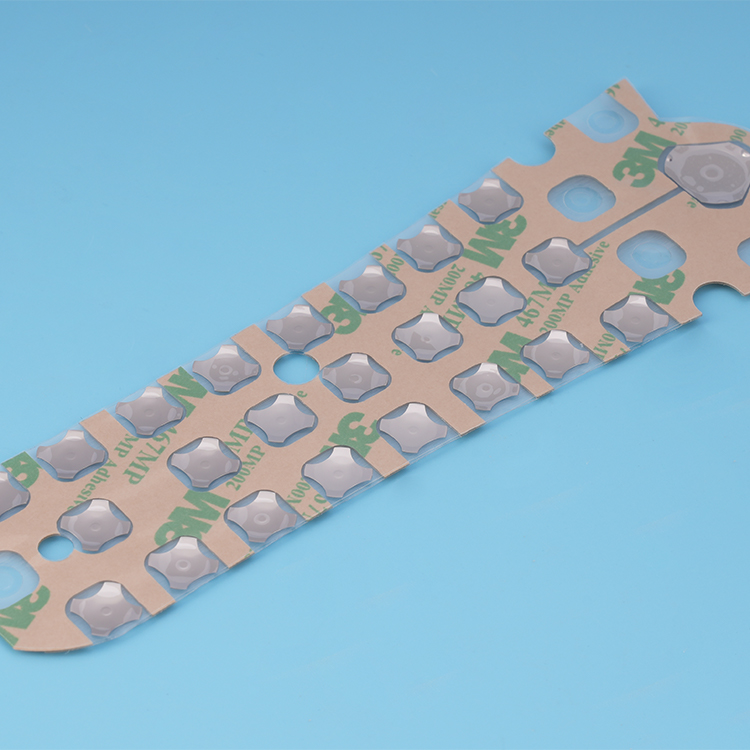

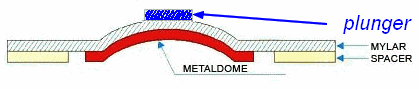

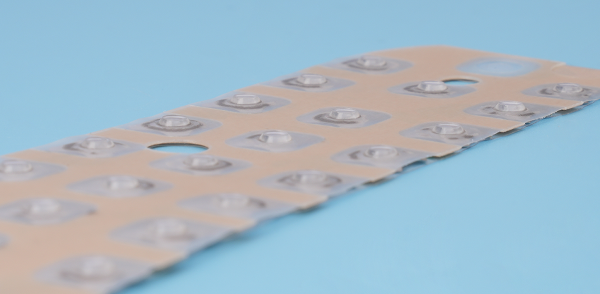

The metal dome is an important component used in membrane switches, PCB boards and other products, and plays an important role in conducting the circuit. When pressed, the circuit is turned on, and when it is released, it is automatically disconnected. If there is a problem with the metal dome, it can affect your product and even your company’s brand. So I would like to tell everyone to pay attention to the following points when choosing a suitable metal dome:

1. Dome life:

Now there are many domes whose service life does not meet the standard. The four legs only have 200,000 to 300,000 times. The price is relatively cheap, but the life of the dome we made can reach 500,000 to 1 million times. After the life test of our products, the metal dome The life of the top can reach 500,000 to 1 million times. The choice of material plays a key role in determining the long life and consistent performance of the metal dome.

2. The force of the metal dome:

The force of the metal dome is the most stringent requirement of foreign customers, that is to say, the force of each metal dome must be uniform, not one high and one low, and it must be controlled within a certain tolerance range (±30gf). The force applied to the metal dome determines the level of tactile feedback experienced by the user, while the actuation life represents the number of times the metal dome can be pressed before its performance begins to deteriorate. Our metal domes are manufactured to design domes that guarantee user experience and long-lasting performance.

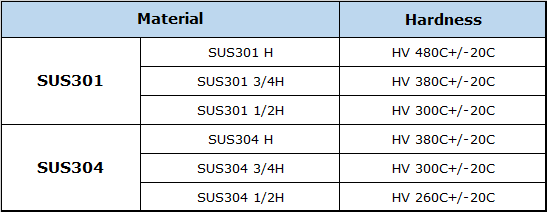

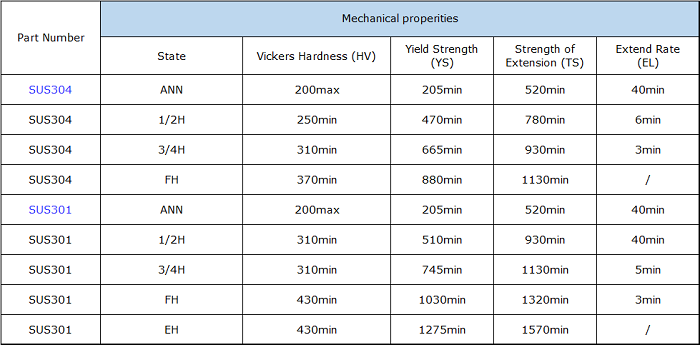

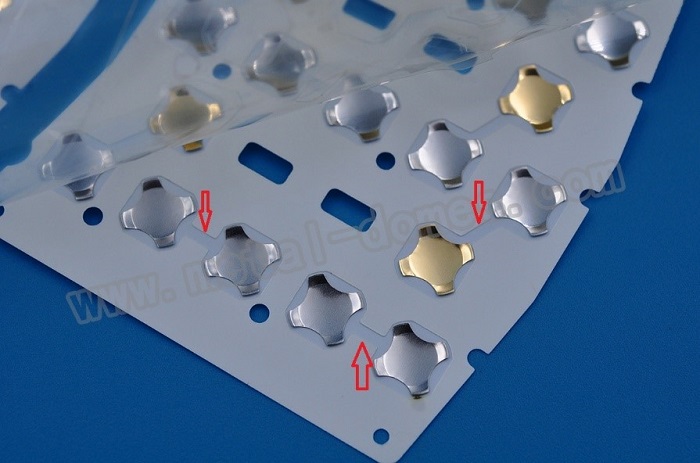

3. Metal dome material:

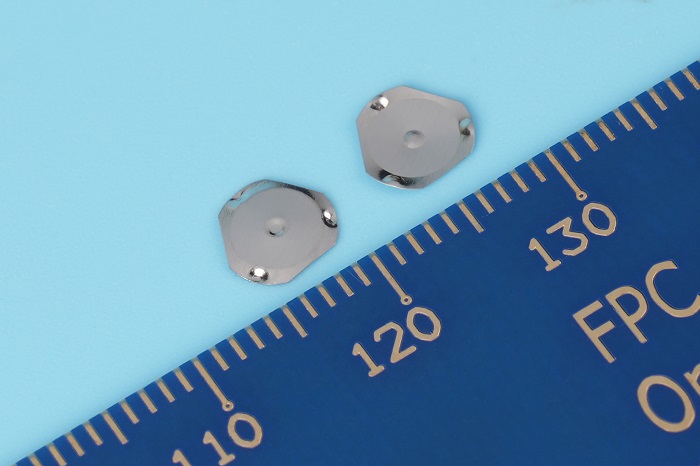

Material selection is critical in determining the overall quality and performance of a metal dome. We offer metal dome materials that are durable, corrosion resistant, and capable of withstanding repeated actuation without losing their shape or function, allowing metal domes to avoid “dead bonds” in use. It is difficult to tell which one is better from the appearance of the material, we can only find better ones and more suitable products for customers through testing.

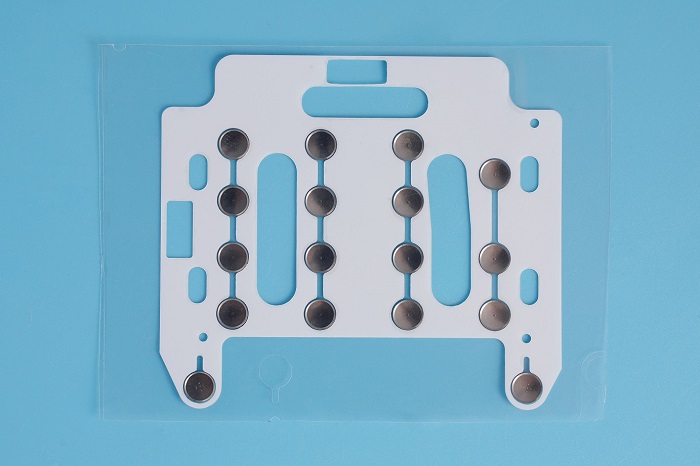

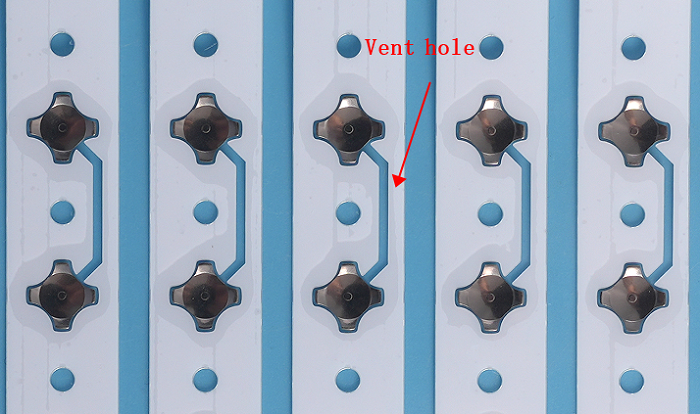

4. Appearance of the metal dome:

When choosing a metal dome, pay attention to whether there is dirt, scratches, grease, crushing, etc. on the appearance, and we will clean and inspect the appearance of the metal dome during production, and check the unqualified products to ensure Every metal dome that leaves our factory meets or exceeds customer expectations.

Best Technology is a company specializing in the production of metal domes and circuit boards. More than 80% of our products are exported to overseas markets. In recent years, we have also developed domestic customers. Our metal dome has a service life of 500,000 to 1 million times, and the force can be controlled within (±15gf). We base our customers on high quality, high service, fast delivery time and good price.