Metal domes are widely used in various tactile switch applications, providing a satisfying tactile feedback when pressed. One intriguing aspect of metal domes is the distinct sound they produce upon actuation. Some metal domes exhibit a crisp and pronounced “snap” sound, while others have a muffled or subdued tone. Have you ever wondered what factors contribute to these differences in sound? In this blog, we will delve into the science behind the auditory feedback of metal domes and explore the factors that influence the sound they produce.

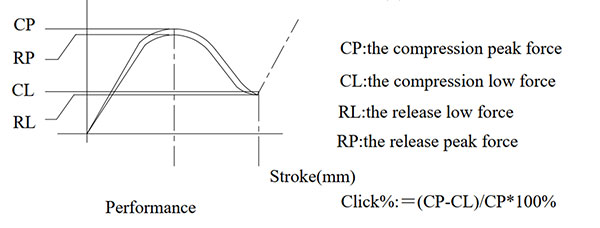

What is Click Ratio?

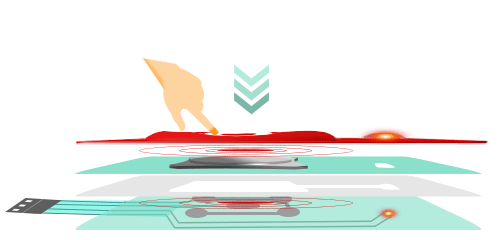

The click ratio is a crucial parameter that determines the auditory feedback of metal domes. It is defined as the difference in force between the compression peak force (CP) and the compression low force (CL) states, divided by the pre-collapse force and multiplied by 100%, that is click ratio=(CP-CL)/CP*100%. In simpler terms, it measures the amount of force required to collapse the dome and create a tactile click. Typically, the click ratio of metal domes is around 50% with a tolerance of ±15%.

The click ratio directly affects the sound produced by metal domes. When the click ratio is higher, approaching the upper limit of the tolerance range, the resulting sound is crisper and more pronounced. On the other hand, a lower click ratio leads to a muffled or softer sound. This correlation between click ratio and sound quality is a result of the specific force distribution and movement of the metal dome during actuation.

Considerations for Optimal Click Ratio

While a higher click ratio may result in a more satisfying sound, it is essential to strike a balance to ensure optimal performance and longevity of the metal domes. Exceeding a click ratio of 70% is generally not recommended for two primary reasons:

1. Rebound Force

When the click ratio is excessively high, the rebound force, or the force exerted by the metal dome when returning to its original shape, becomes lower. This can lead to a phenomenon known as “dome sinking” over time, where the dome fails to fully regain its original shape after multiple actuations. Dome sinking can adversely impact the tactile feedback and the overall performance of the switch.

2. Lifespan

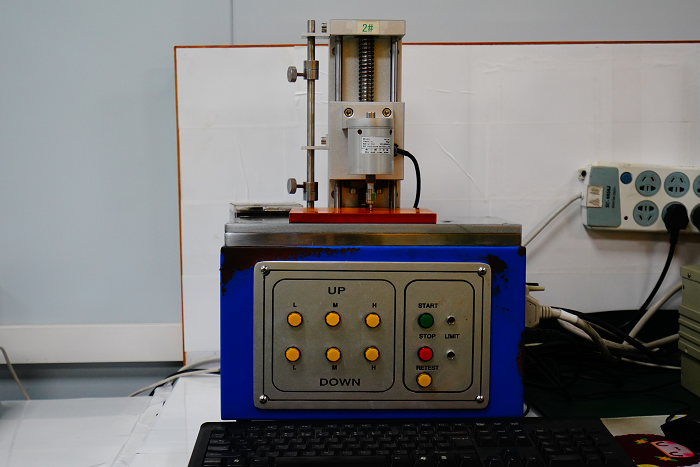

Metal domes are designed to withstand numerous actuations without experiencing significant degradation in performance. However, excessively high click ratios can put additional strain on the domes, potentially reducing their lifespan. The repeated stress on the metal dome can lead to fatigue and premature failure, compromising the reliability of the switch.

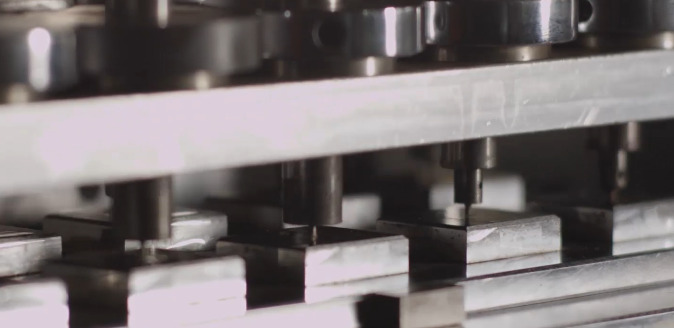

(Life span tester)

3. Optimizing Sound and Performance

Achieving the perfect balance between sound quality and performance requires careful consideration of the click ratio. Manufacturers strive to optimize the click ratio within the acceptable tolerance range to ensure a crisp and satisfying sound while maintaining the long-term reliability of the metal domes. This delicate balance ensures a tactile switch that not only provides an enjoyable user experience but also meets the rigorous demands of various industries.

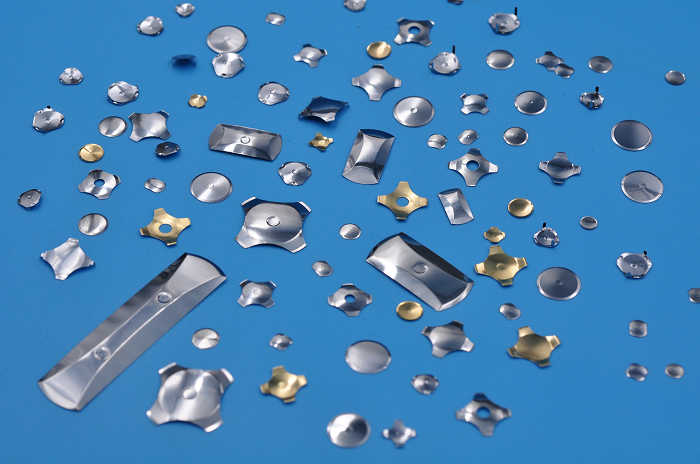

From above, we know the “snap” sound produced when pressing metal domes is influenced by the click ratio, which determines the force distribution and movement of the domes during actuation. By carefully optimizing the click ratio within an acceptable range, manufacturers can achieve a balance between sound quality, switch performance, and longevity. This delicate balance ensures that metal domes not only provide an enjoyable tactile experience but also meet the demands of diverse applications in industries such as electronics, automotive, and consumer goods.

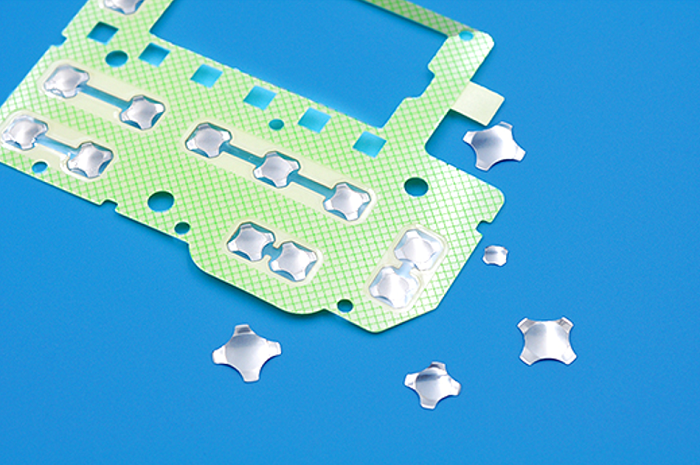

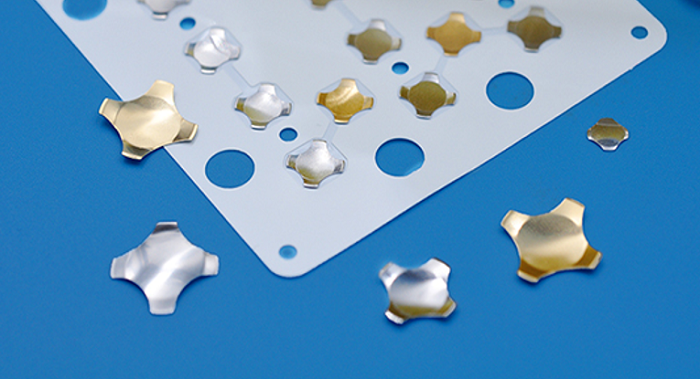

Best Technology specialize in the production, sales and service of metal domes, dome array, light guide film and OCA products. The metal dome range includes four-legged, triangle, round and oblong types which can satisfy most requirements. Freely contact us if you have any projects that need metal domes.