When you are designing a metal dome switch for your devices, you must know the design rules or the standard limitations firstly. So how do you know your metal dome design is right and suitable for your applications? Here in, we summarize six frequently asked questions on snap dome switches that we get from our engineers.

1.What Are Classifications of Tactile Metal Domes?

Currently, there are seven methods for the classification of metal dome switches.

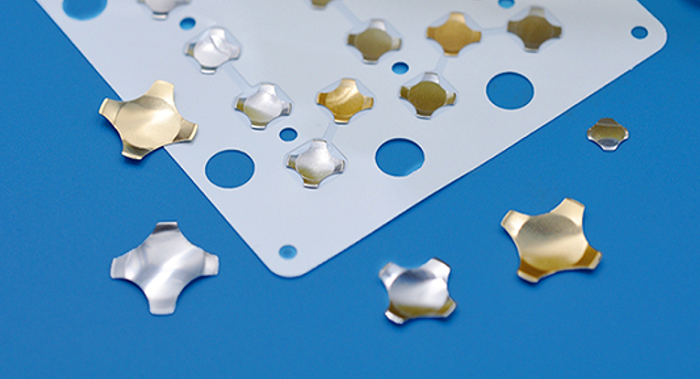

- Classification by shape

This is the most intuitive classification for metal domes (snap domes as well), that is by shapes. There are Round Metal Dome, Oblong Metal Dome, Triangle Metal Dome and Four-leg Metal Dome (also called Cross Metal Dome)

- Classification by the number of contact dimples

No dimple, single dimple and multi dimples metal dome. These can be checked on the surface of snap domes.

- Classification by the surface treatment

We also can recognize it from its surface finishing. Normal metal domes are in stainless steel, some customers require plated with Nickel, Silver and Gold.

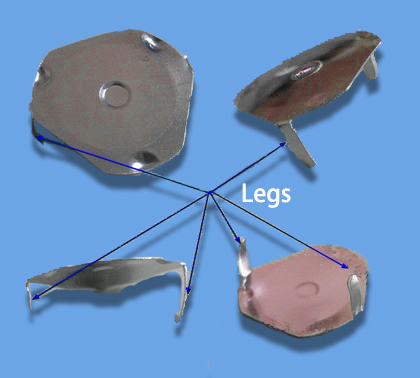

- Classification by whether they have legs or not

Metal dome with legs or metal dome without legs. (Usually, since the other domes seldom have legs, this method only works with the triangle metal domes.)

- Classification by the force

The metal dome can be classified by high force metal dome and low force metal domes.

- Classification by the click ratio

Metal domes can be divided into high click ratio and low click ratio metal domes.

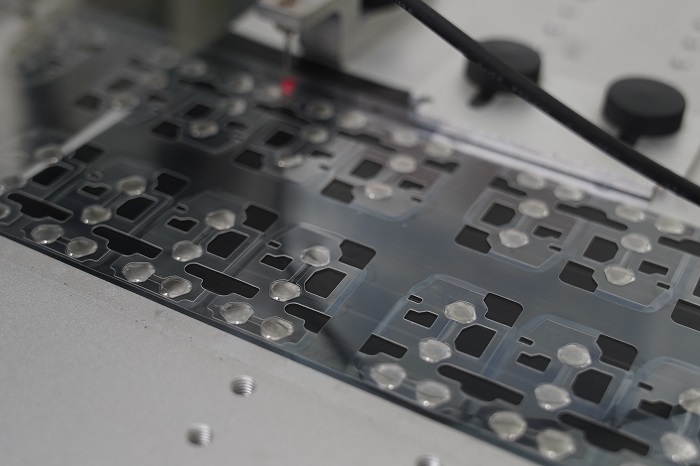

2.What is the Package Method for Metal Domes?

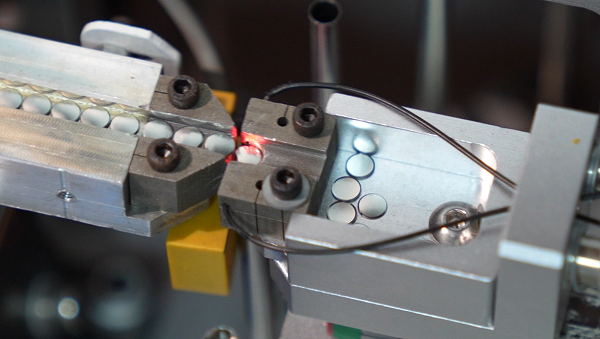

Usually, we have 4 types of packaging methods for metal domes, you can choose according to your convenience.

- The most common package is PET bag, it is also called bulk or loose.

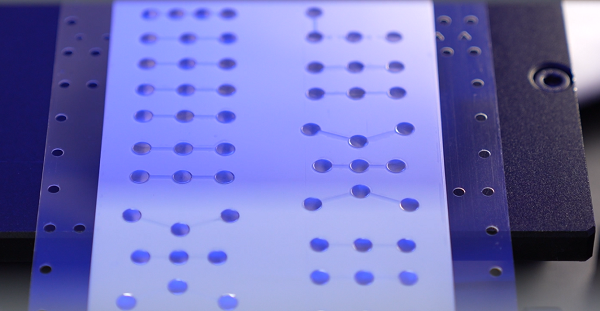

- Placing metal domes in customized PET adhesive tape, which is named as dome array or

dome sheet.

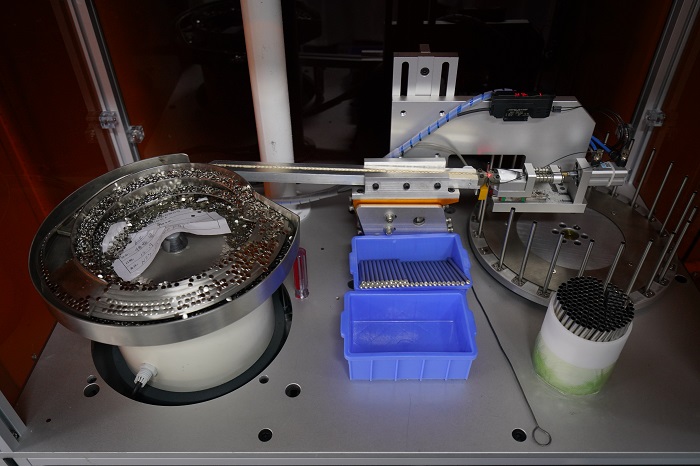

- Tape & reel package. This package is mainly used for SMT peel and place machine.

- Tube packaging. This method is not used commonly, for which different shapes require

different tooling and different tube sizes, hence if there is no large order volume, the cost will be very high.

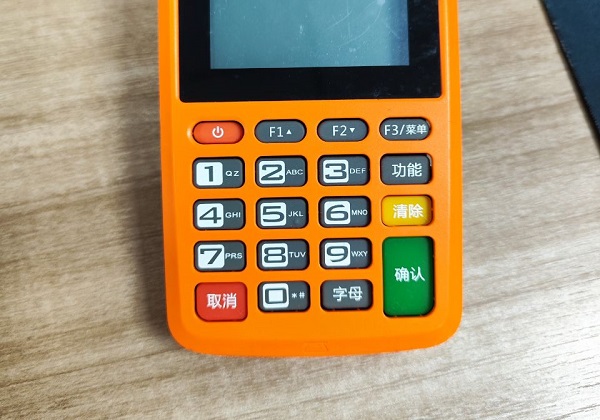

3.What Are the Advantages of Metal Dome Switches Over Other Switch Types?

Metal dome switches offer several advantages that make them a preferred choice in many applications. Some key benefits include:

Durability: Metal dome switches are incredibly durable and can withstand millions of actuations without wearing out.

Reliability: They provide consistent tactile feedback, ensuring that every keypress or input is registered accurately.

Tactile Feel: Metal dome switches offer a distinct tactile feel, which many users find satisfying.

Longevity: Their long lifespan reduces maintenance and replacement costs over time.

4.Are Metal Dome Switches Compatible with Different Circuit Designs?

Yes, metal dome switches are compatible with various circuit designs, including flexible circuits. Their low profile and conductive nature make them suitable for integration into different electronic systems, providing tactile feedback and reliable electrical connections.

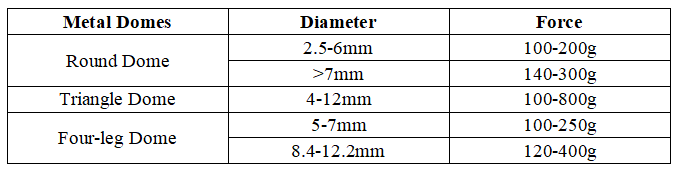

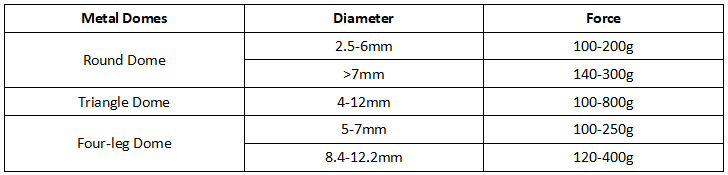

5.What is the Most Commonly Used Force Range for Metal Dome?

(PS: For round metal dome, when its diameter is larger, the force can even reach 200g to 400g.)

As we know that the force of metal domes is also related to the lifetime. Therefore, the magnitude of force still depends on the customer’s requirement. if the customer has no requirements about the lifetime, we can increase the force at discretion as well.

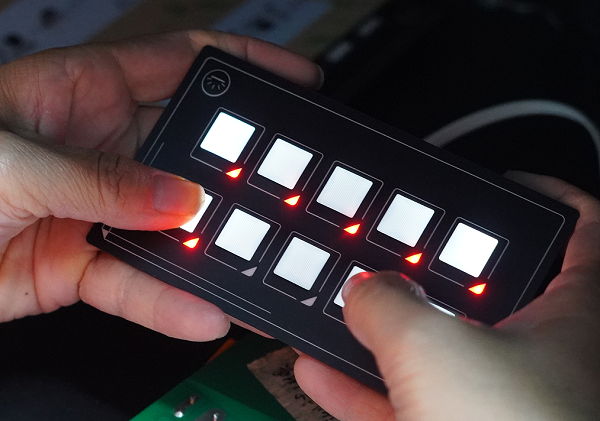

6.What Parameters Should We Know Before Designing the Dome Array?

a.The position of key, the design file should dedicate the center point of the key.

b.The position of the hole, e.g., LED, position hole, soldering point.

c.The outline of the whole product, outline is generally corresponding to the outline of the PCB.

d.Whether to brush EMI, add double-sided tape, add light guide.

e.Specifications of metal dome, for example: shape, diameter, force and material of metal dome.

f.Tolerance requirements, such as dimensional tolerance, tolerance between buttons and buttons, etc.

If you have any other questions, welcome to reach us at any time~