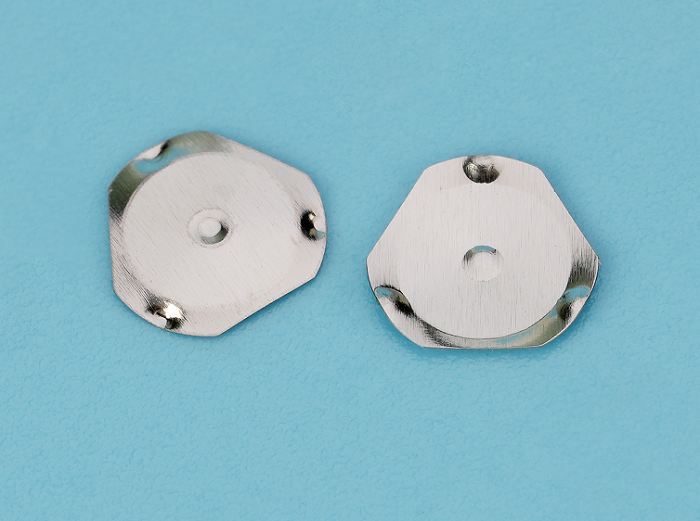

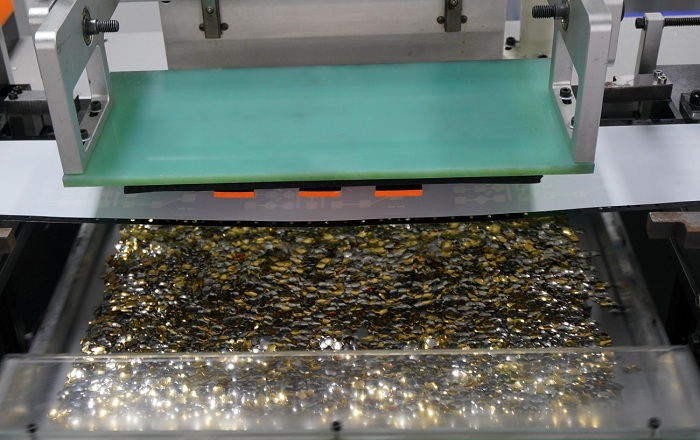

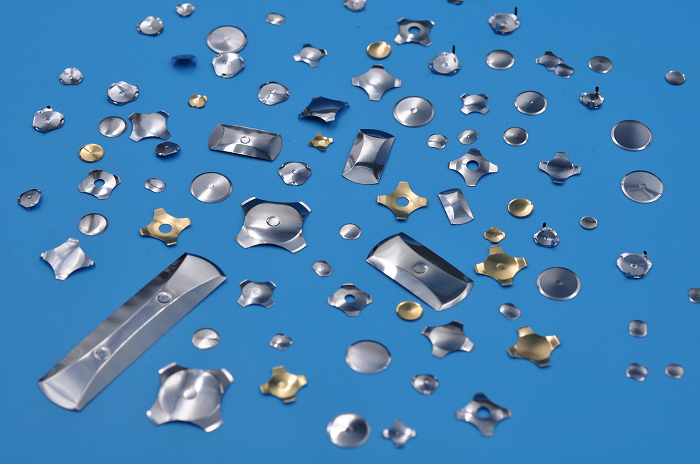

Metal Dome Switches are a common electronic component widely used in industrial fields. Metal Dome Switches are mainly composed of metal domes and PET panels. Its main function is to realize electronic control of mechanical switches and improve the operational convenience and reliability of the equipment. Many equipment control panels use Metal Dome Switches, which are widely used in electronic communications, electronic measuring instruments, industrial control, medical equipment, automotive industry, smart toys, household appliances and other fields. Below I will give you a detailed introduction to the application and main functions of Metal Dome Switches in industry.

Metal Dome Switches in Industrial Applications

Mechanical control

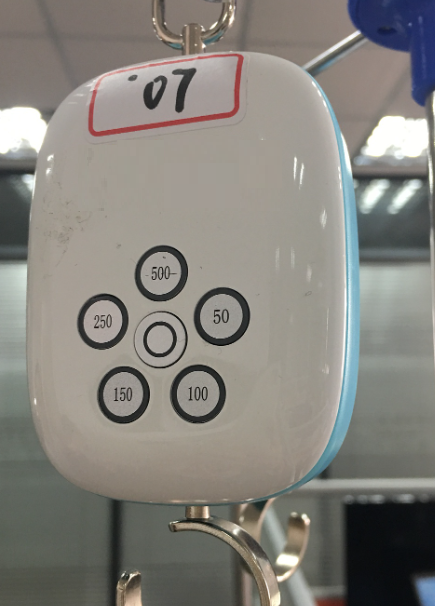

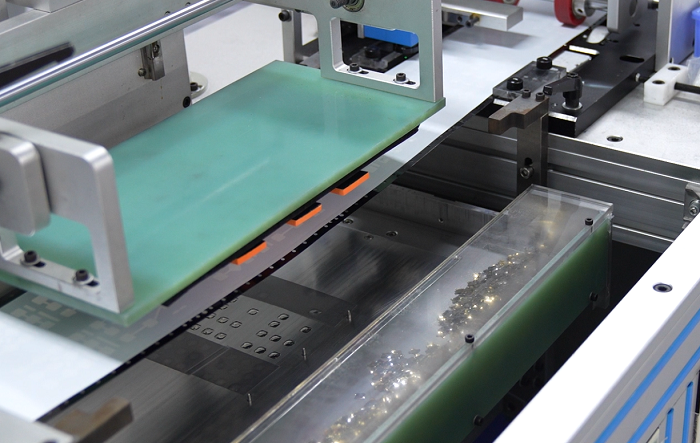

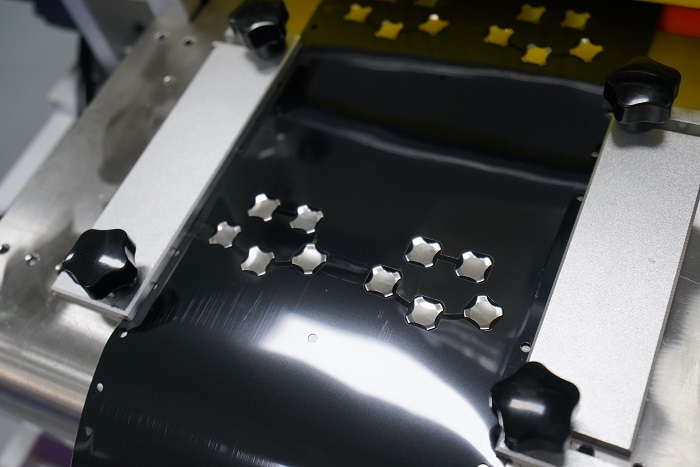

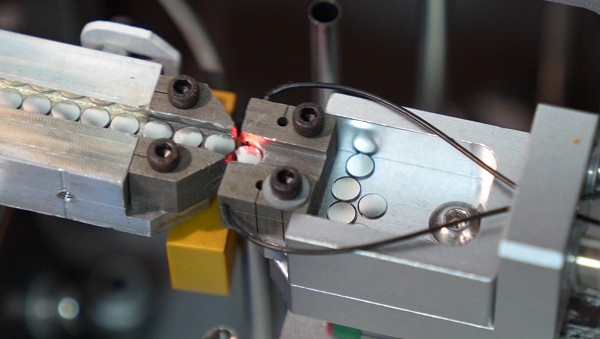

Metal Dome Switches can be used as control switches for mechanical equipment in industry, installed on operating equipment. Realize the functions of starting, stopping, adjusting and switching the equipment. The main requirement in industrial equipment is the accuracy and sensitivity of metal domes. The metal domes produced by Best Technology can be designed according to different needs to improve the accuracy of the domes in use. In industrial applications, through simple touch or press operations, Metal Dome Switches can generate switching signals to control the operating status of mechanical devices and improve the operational convenience of equipment.

electronic display

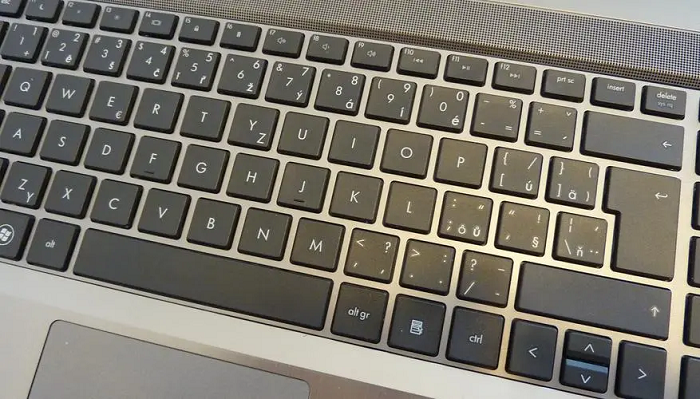

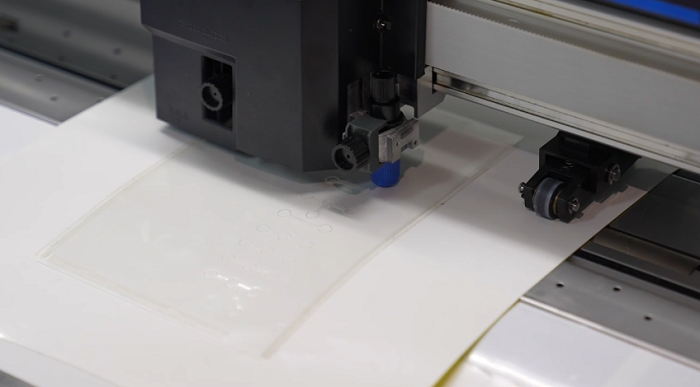

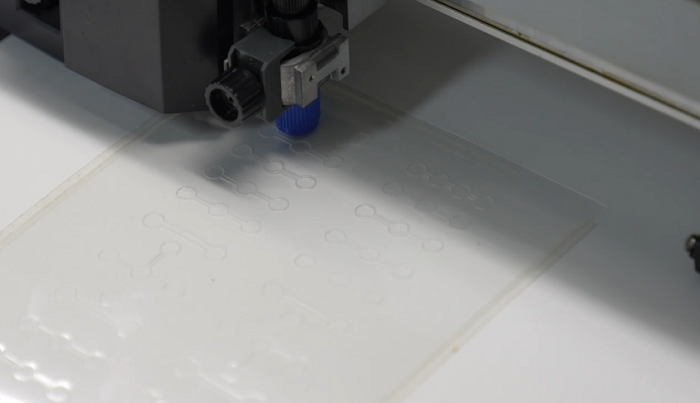

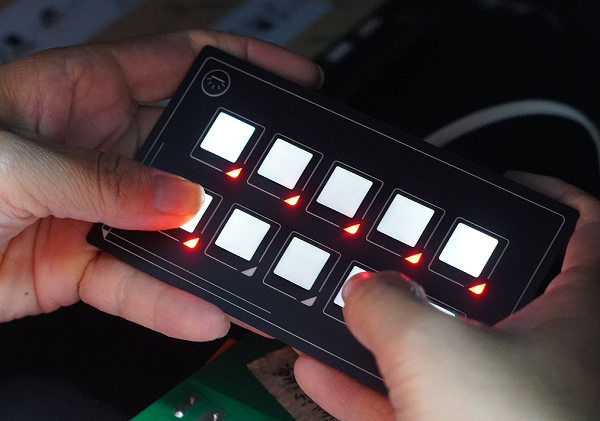

Metal Dome Switches are commonly used in electronic display devices, such as touch screens, digital cameras, etc. By touching the Metal Dome Switches panel, users can control and operate the display device. The bulges on the Metal Dome Switches can serve as a reminder. The lower end of the bulge is the location of the metal dome, which can serve as a reminder. At the same time, there will also be a pattern printed on the top. Metal Dome Switches have high sensitivity and touch feedback, which can provide users with a good experience.

Main features of Metal Dome Switches

Industrial controllable

Metal Dome Switches play an important role in industrial automation control systems. It can be used in conjunction with other sensors and actuators to achieve automated control of industrial equipment. Metal Dome Switches have a good feel in the application. After testing, the key strength is moderate; a crisp “click” sound can be heard when operating. Metal Dome Switches improve production efficiency and quality by sensing external physical changes or signal inputs and triggering corresponding control actions.

Durable and reliable

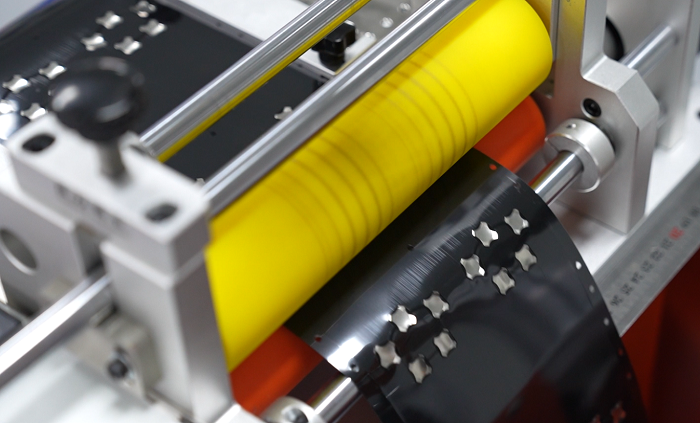

Metal Dome Switches are durable and reliable and can operate stably for a long time in harsh industrial environments. Its outer film material is waterproof, dustproof, and anti-corrosion, protecting the internal electronic components from damage. The metal dome in Metal Dome Switches has been tested to last up to 5 million times. At the same time, Metal Dome Switches are designed and manufactured with high precision to ensure the sensitivity and stability of the switches.

Space Saving

Metal Dome Switches are designed to be compact and take up little space, making them suitable for limited installation spaces. Metal Dome Switches panels are easy to install in industrial control panels. They can be flexibly installed on the surface, edges or curved parts of the equipment to improve the overall aesthetics and compactness of the equipment. It does not affect the beauty of the product during use. The pattern and button style on the Metal Dome Switches panel can be designed according to product requirements. Special ink is used to ensure that it does not fade after long-term use.

Metal Dome Switches have a wide range of applications and are involved in various industries. Today we will introduce common industrial control panel applications here. The main functions are in mechanical control, electronic display, automatic control, durability and reliability, and space saving. With the continuous development of technology, Metal Dome Switches will continue to play an important role in the industrial field, providing more convenience and innovation for equipment operation and control. If you have Metal Dome Switches and metal dome applications, you can consult us and we will provide you with a satisfactory explanation!