SMD tactile switch is a widely used chip component, mainly produced through surface mounting technology. It is a switch type mainly used in various electronic products at present. Since there are many manufacturers of SMD tactile switches, and the products have various sizes and specifications, and the quality is also uneven, this leads to customers not knowing how to make a choice when choosing. The following is based on the structure and working principle of SMD tactile switch. Select the appropriate SMD tactile switch.

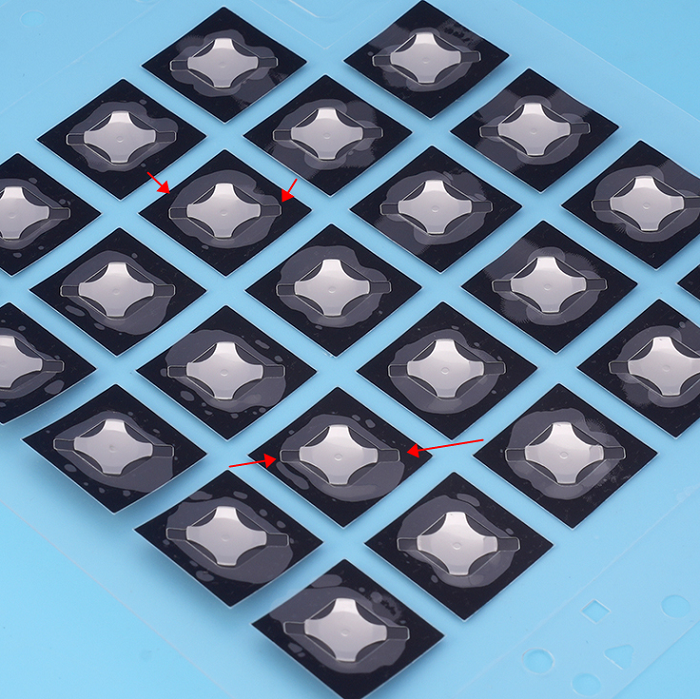

SMD tactile switch is mainly divided into the following two types according to different design principles. One is to use the metal dome inside the switch to turn the switch on and off. The feel of this switch is relatively good, because it is made of metal. When the switch button is pressed to a certain extent, there will be a ticking sound. , this kind of feedback is very good. Many mobile phones now use this principle in their design, such as virtual buttons. In order to make them have the same feel as physical buttons, various vibrations and sounds are designed to create a feeling that is the same as physical buttons. a feeling of. The other is to use conductive rubber to turn the switch on and off. The feel of this type of switch is slightly worse than the previous one, but the contact resistance is large, about 10,000 times that of the previous one.

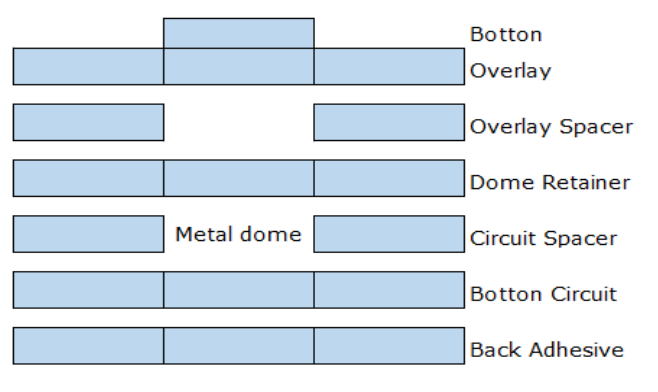

Structure of SMD tactile switch

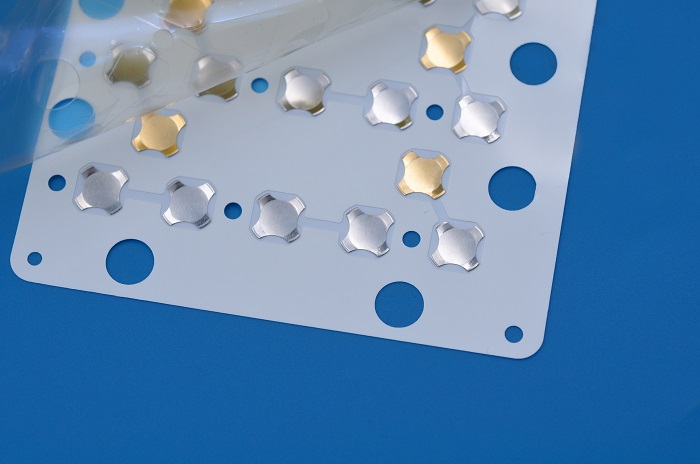

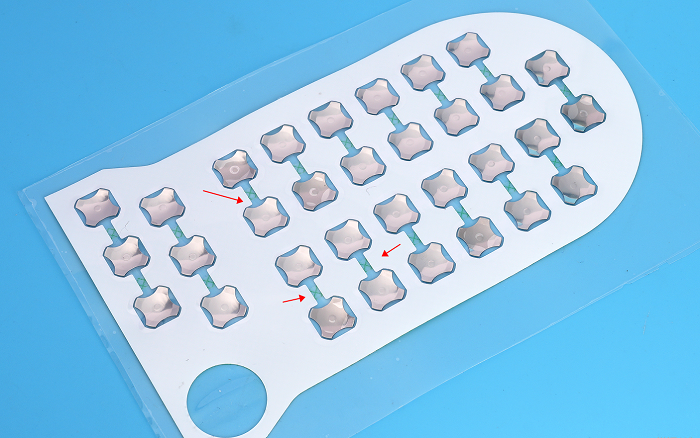

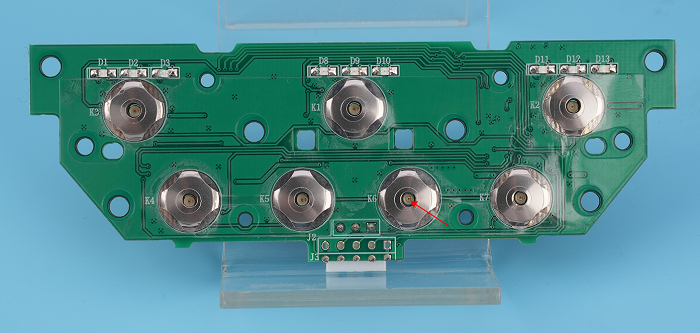

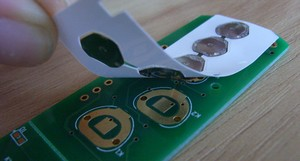

The SMD tactile switch is mainly composed of five parts: cover, button, dome, base and pins. The cover is mainly used for sealing protection to prevent dust and other pollutants from corroding the internal parts of the switch; the main function of the button is to withstand the pressure of external force, and then conduct the pressing force to the dome; and the dome is an SMD tactile switch A very important component in the circuit breaker, it mainly relies on changes in the force of the dome to turn the switch on and off, forming a closed circuit; the function of the pins is mainly to connect with the circuit.

SMD tactile switch working principle

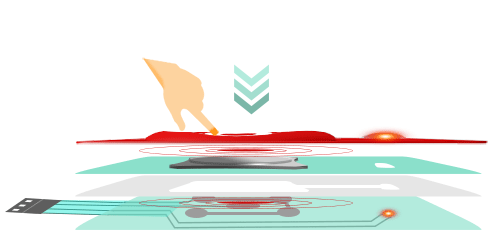

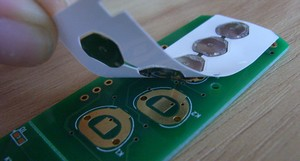

The working principle of the SMD tactile switch: When the button of the switch is pressed, the dome inside the switch will deform under the action of pressure and contact the solder tab, which will connect the pin circuit of the switch; and when the dome When the pressing force is removed, the dome will immediately separate from the solder tab and return to its original state. At this time, the two sets of pins of the SMD tactile switch are no longer connected, causing the entire switch circuit to appear disconnected.

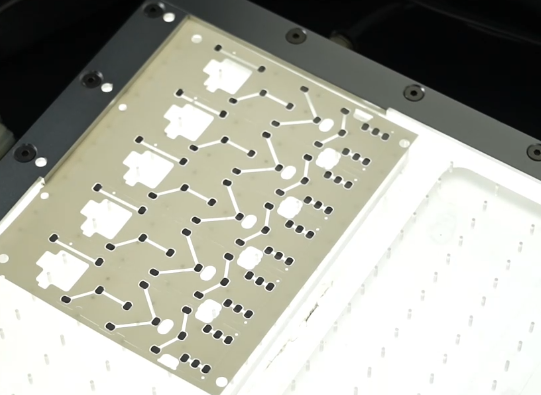

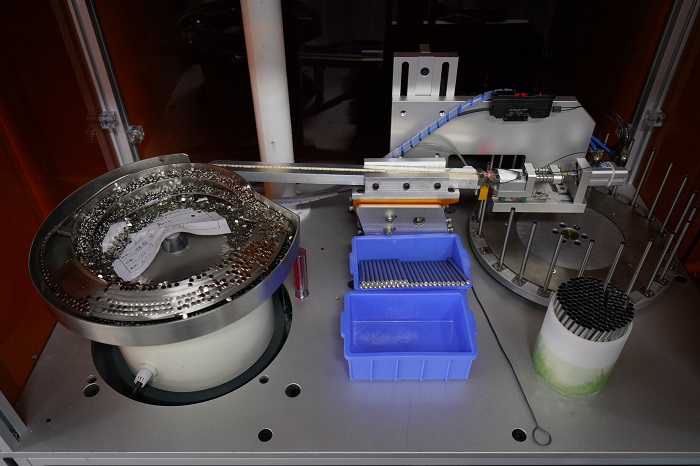

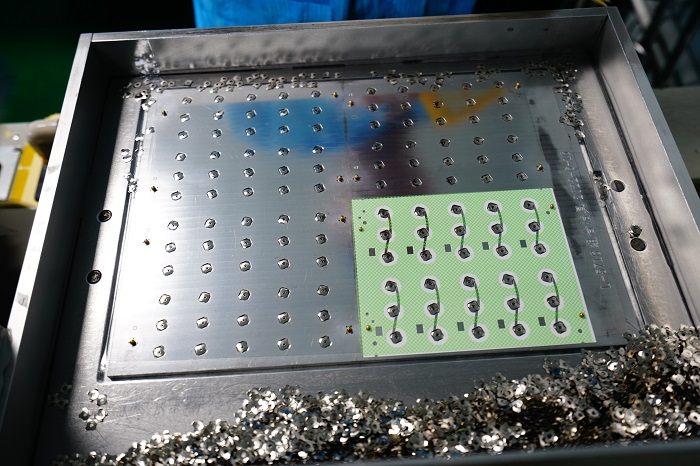

The production and manufacturing of SMD tactile switch can be well understood from the structure and working principle. So how to choose a suitable product? When the patch clear switch is used, in order to improve the performance of the switch, the contact resistance will be reduced. Therefore, customers will choose the material of the chip clear switch. Both brass and phosphor copper have the function of reducing resistance. In addition, the resistance can be reduced by surface treatment of the metal dome. When choosing a tactile switch, you must choose a reliable product, mainly for stable performance and safe and continuous operation.

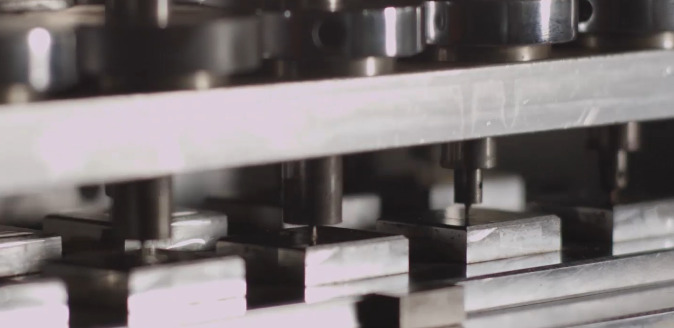

The metal dome plays an important role in the SMD tactile switch, so when choosing a suitable tactile switch, the product quality of the metal dome should also be considered. Best Technology is a metal dome manufacturer with rich experience. In the production of SMD tactile switches, it strictly controls product quality and strictly abides by production specifications. If you need SMD tactile switch or metal dome in your product, you can contact us at any time for consultation!