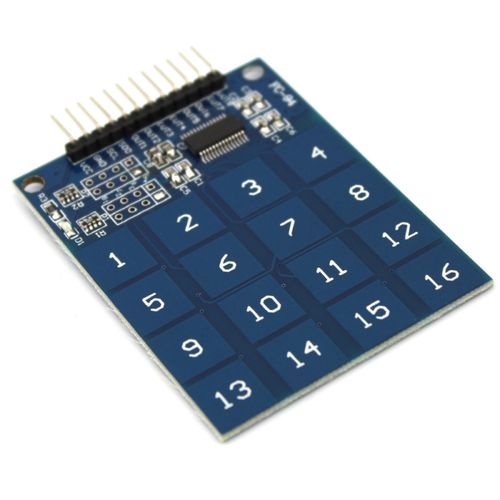

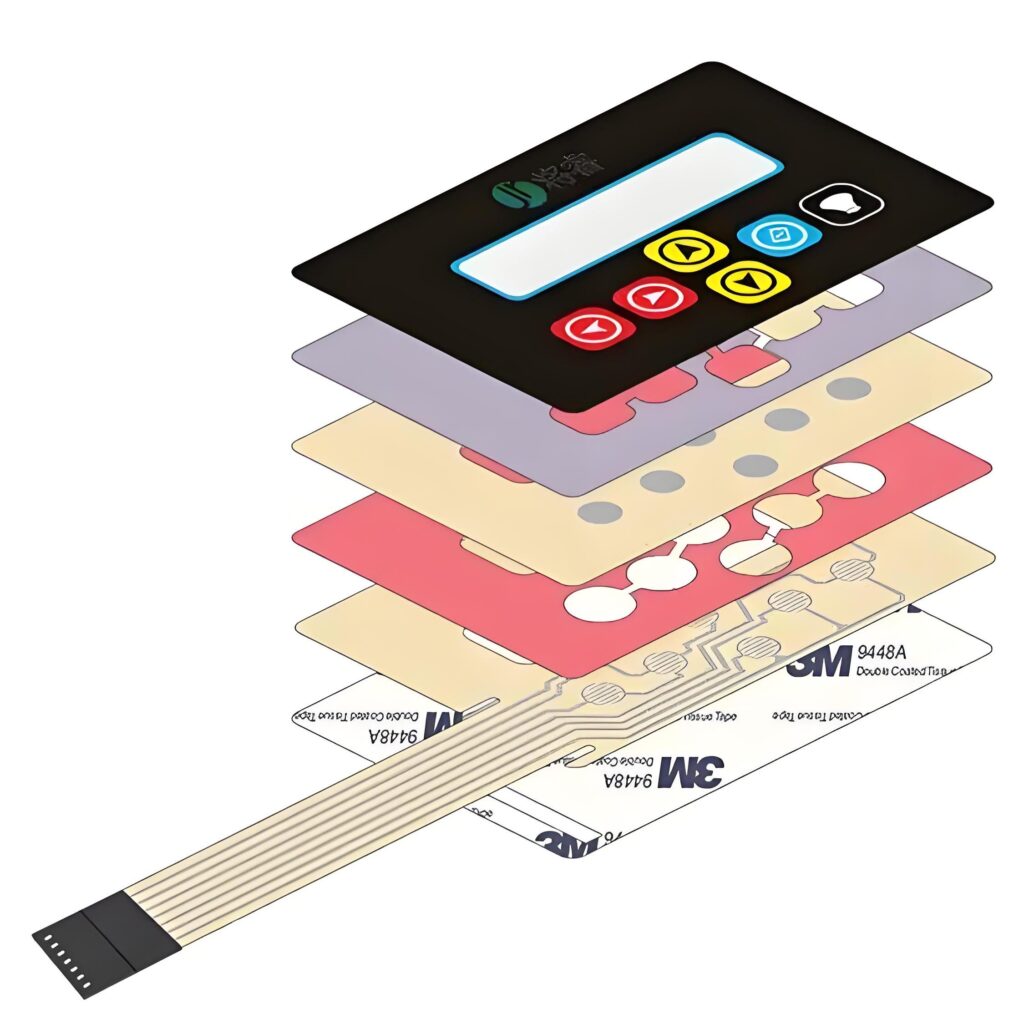

A capacitive switch circuit is a circuit that uses capacitance changes to achieve a switch function. It usually consists of a capacitor and a detection circuit. When an object touches the capacitor, the capacitance changes, the detection circuit detects this change, and outputs a switch signal according to the logic.

What is a capacitive switch?

A capacitive switch is an electronic switch that uses capacitance changes to control the on and off of a circuit. It usually consists of two electrodes, one is a fixed electrode and the other is a movable electrode or a sensing electrode. When no external object approaches or touches it, the capacitor is in a specific initial state.

When an object approaches or touches the sensing area of ??the capacitive switch, the electric field distribution between the electrodes will change, resulting in a change in the capacitance value. After this change is detected by the detection circuit, it is processed by the signal, triggering the switch action and controlling the on and off of the circuit.

In the touch screen of a smartphone, when a person’s finger approaches or touches the screen, the capacitance at a specific position on the screen will change, so that the touch position will be detected by the system and respond accordingly.

How does a capacitor switch work?

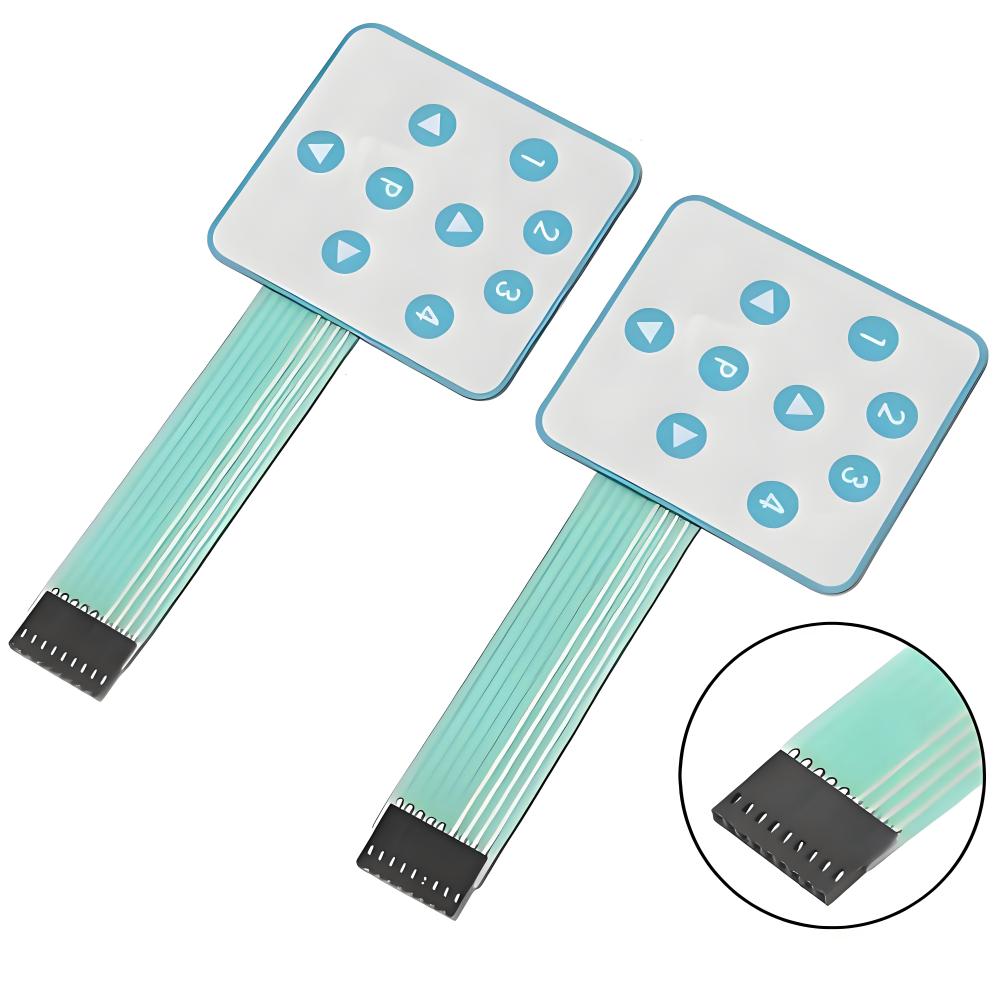

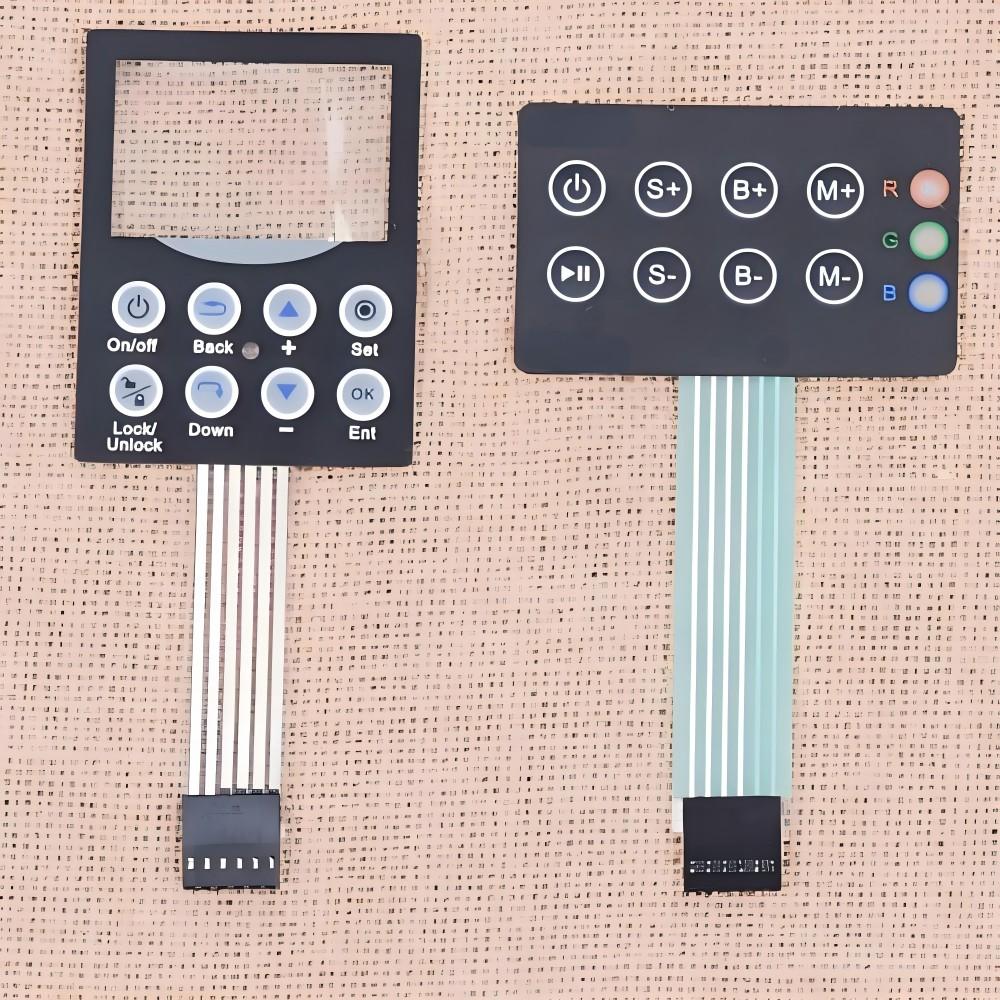

Capacitive switches mainly include capacitive proximity switches and capacitive touch switches.

Capacitive proximity switch: The measuring head is usually a plate of a capacitor. When no object approaches, there is an initial capacitance value. When an object approaches, whether the object is a conductor or an insulator, the dielectric constant of the capacitor will change, resulting in a change in capacitance value. The detection circuit monitors the capacitance change and converts it into an electrical signal change, triggering the switch action when the threshold is reached.

Capacitive touch switch: There is a capacitor-like structure inside, and there is an initial capacitance value when it is not touched. When touched, the human body and the touch sensing surface form an additional capacitance to increase the total capacitance value. The detection module monitors the capacitance change, and when it exceeds the threshold, it is considered that there is a touch action, and the signal is transmitted to the control circuit to control the switch on and off.

What is the function of a capacitive switch?

1. Non-contact control

Avoid mechanical wear, extend service life, and is suitable for frequently operated equipment.

Ensure operational safety and hygiene in special environments (such as high voltage, strong corrosion, and high hygiene requirements).

2. High-precision sensing

Touch detection is sensitive and can be operated by light touch, such as on mobile devices.

It has proximity sensing function, strong anti-interference ability, and can work stably in complex electromagnetic environments.

3. Multifunctional integration

Different functions and multiple control methods (single-point, multi-point touch, sliding, etc.) can be realized through programming, and can also be linked with other devices.

Some switches have status feedback function.

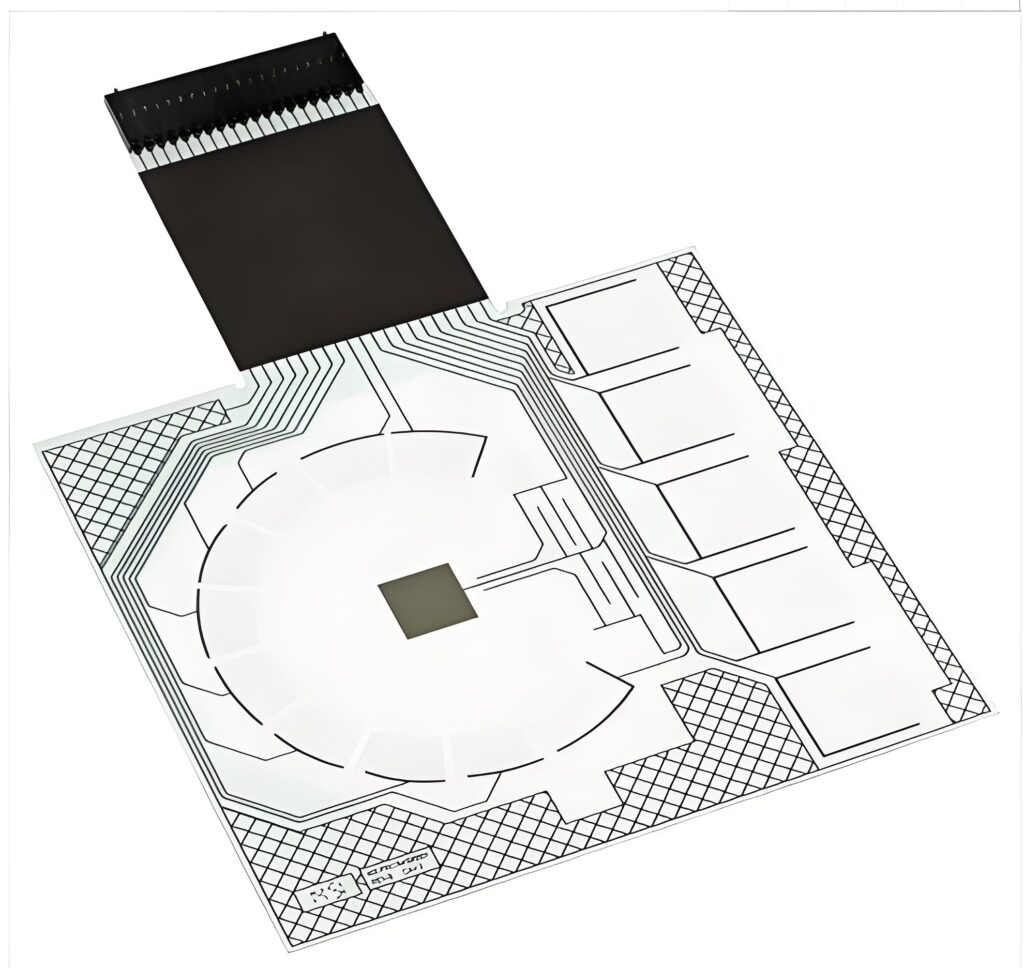

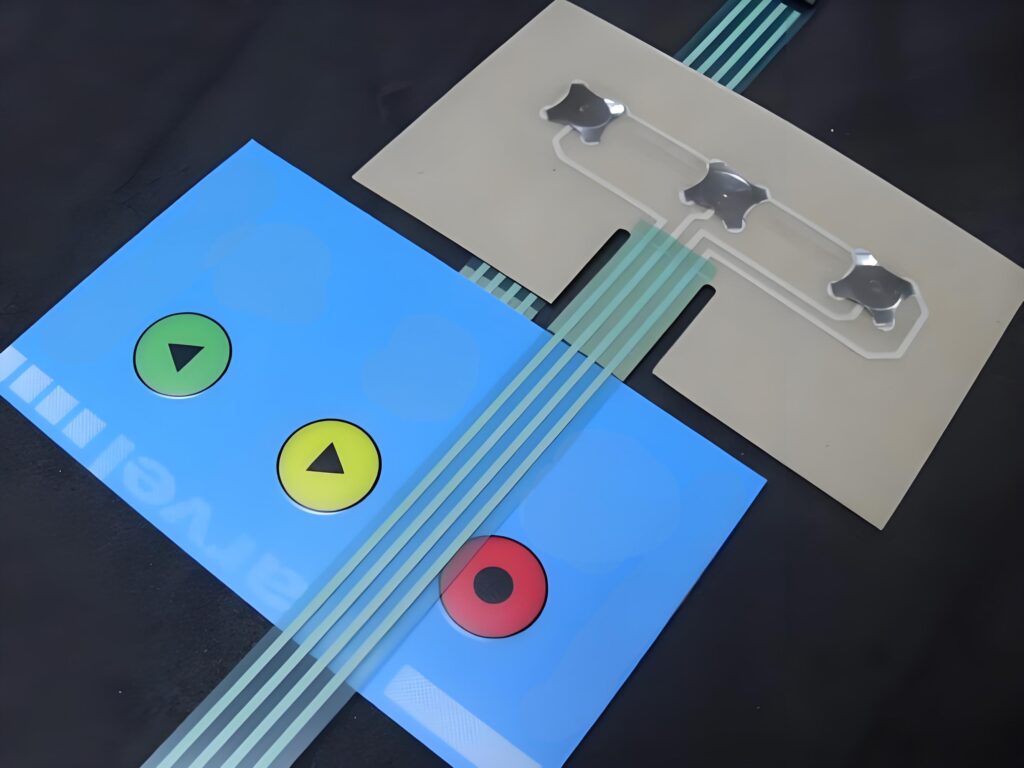

4. Aesthetics and design flexibility

The appearance is simple and beautiful, and the flat design is easy to integrate with the equipment.

Flexible design, shape and size can be designed as needed, and can be customized to meet personalized needs.

Are electro capacitive switches good?

Capacitive switches have the following advantages:

High sensitivity and non-contact detection: Capacitive switches determine whether the object is close by detecting the capacitance change between the target object and the sensor, avoiding wear and pollution caused by contact friction, and improving the service life of the sensor.

Strong anti-interference ability: In complex industrial environments, capacitive switches can effectively suppress electromagnetic interference and mechanical vibration by optimizing circuit design and adopting advanced signal processing technology, ensuring the stability and reliability of sensors in harsh environments.

Strong adaptability: Capacitive switches are suitable for the detection of various materials, whether metal, plastic or liquid, as long as the dielectric constant is different from that of air, it can be detected by the sensor.

What is capacitive switch vs mechanical switch?

1?Working principle

Capacitive switch: uses the capacitance effect to realize the switch operation. When the human body or other conductive objects approach or touch the switch, the capacitance of the capacitor will change, thus triggering the switch action.

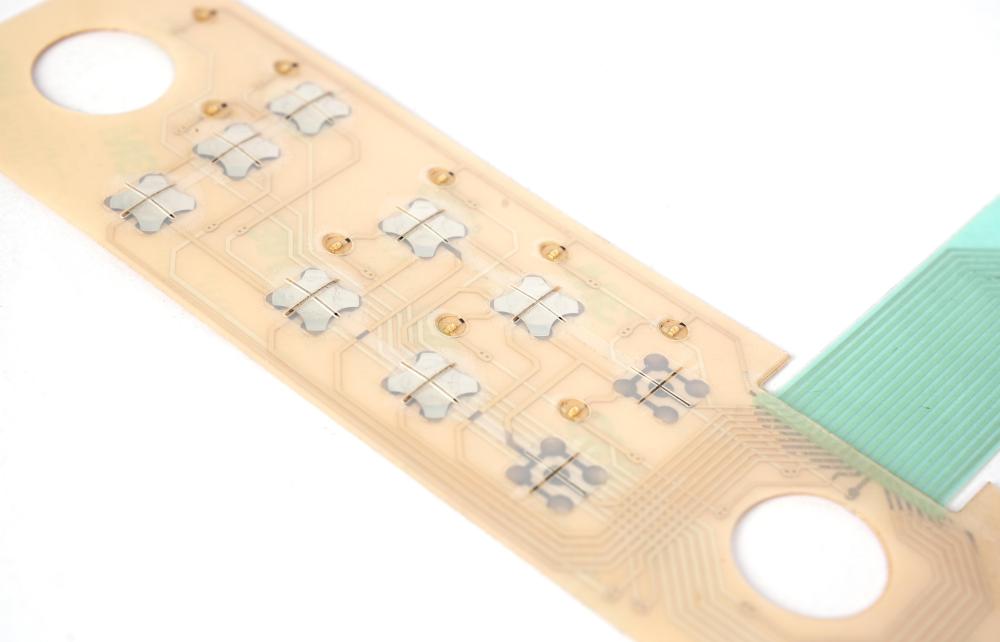

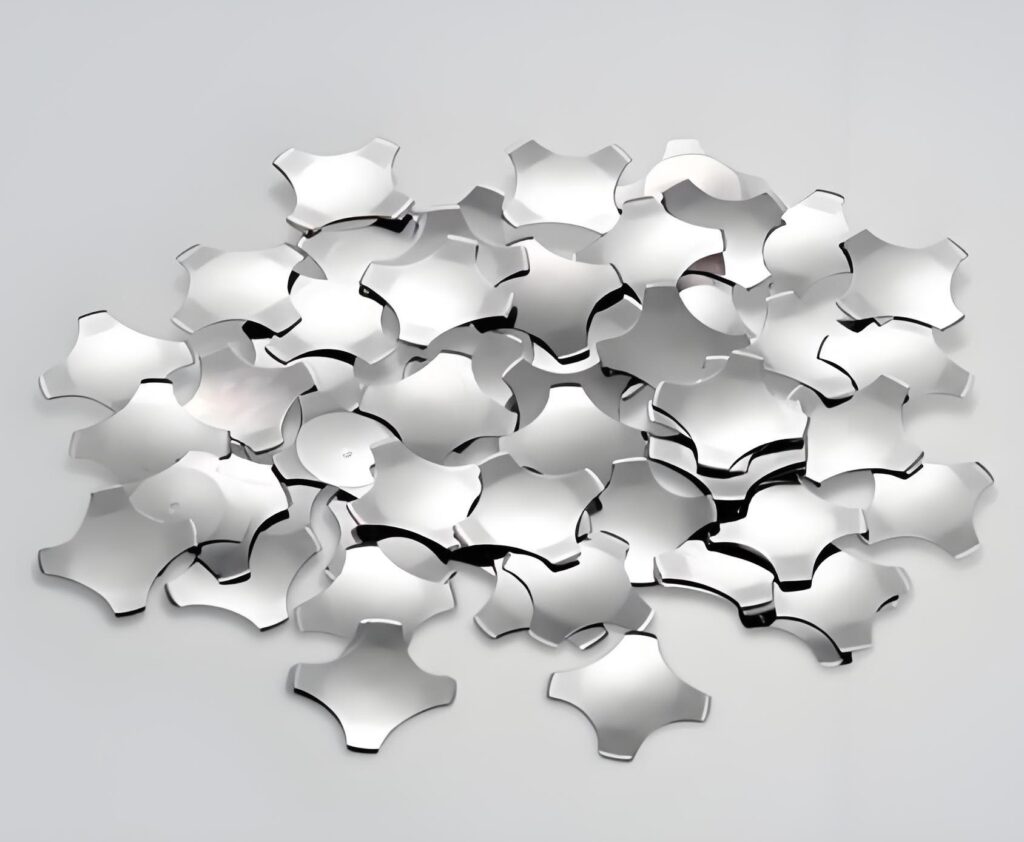

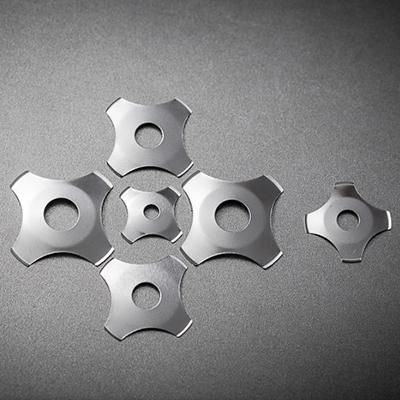

Mechanical switch: The switch action is completed by mechanical principle. It is usually composed of a button and a metal dome. When the button is pressed, the metal dome bends, the contact is connected, and the circuit is closed; when the button is released, the metal dome recovers, the contact is separated, and the circuit is disconnected.

2?Sensitivity and life

Capacitive switch: It has high sensitivity and long life. Since there is no mechanical contact, it has a long life. In addition, the response speed of capacitive switch is fast, which is suitable for occasions requiring high sensitivity and fast response.

Mechanical switch: Although the structure is simple and the cost is low, its life is relatively short due to mechanical wear and aging problems. The response speed of mechanical switch is slow, which is suitable for occasions with low response speed requirements.

How is a touch switch different from a normal switch?

1. Working principle

Touch switch: Control the on and off of the circuit through human contact, using the human body as a conductor. When the human body touches the switch, the circuit is closed, thereby achieving the purpose of controlling the circuit.

Ordinary switch: Control the on and off of the circuit through mechanical action, using the contacts inside the switch. When the switch is pressed or rotated, the contacts are closed or disconnected, thereby achieving the purpose of controlling the circuit.

2. Usage scenario

Touch switch: Due to its contactless characteristics, it is suitable for scenarios that need to avoid contact pollution or require frequent switching, such as medical equipment, laboratory equipment, etc.

Ordinary switch: Suitable for most home and industrial scenarios, such as lighting, electrical appliance control, etc. The function of ordinary switches is relatively simple, mainly used to switch power, such as controlling the switch of lamps.

3. Safety

Touch switch: Due to the working principle, there may be a risk of accidental touch, especially in a humid environment, the human body resistance is reduced, and accidental touch is more likely to occur.

Ordinary switch: Relatively safe, the switch action will only be triggered when pressed or rotated.

4. Price and durability

Touch switch: The price is high, but due to the lack of mechanical parts, the durability is poor, and the use effect is easily affected by factors such as dust and moisture.

Ordinary switch: The price is low, the structure is simple, the durability is strong, and it is suitable for long-term use.

What are the pros and cons of capacitive touch?

The advantages of capacitive touch include:

Intuitive operation: Capacitive touch screens support multi-touch, and the operation is more intuitive and interesting.

Not easy to touch by mistake: Capacitive touch screens only sense the current of the human body, and will not react when other objects touch, avoiding the possibility of accidental touch.

High durability: The capacitive touch screen has a good structural design, which can effectively prevent dust and stains from affecting the contact position, and has dustproof, waterproof and wear-resistant characteristics.

No need to press: Capacitive touch only requires touching, and there is no need to press like resistive touch.

The disadvantages of capacitive touch include:

Uneven light transmittance: There is a problem of color distortion, which may cause blurred images and characters.

Susceptible to environmental influences: Changes in ambient temperature and humidity will affect the accuracy of the capacitive screen.

Fragile: The outermost glass protective layer is scratch-resistant but easily broken.

Gloves are not supported: Capacitive screens may not work properly in humid weather or when wearing gloves.

Capacitive switch circuits are circuits that use capacitance changes to achieve switching functions. They consist of capacitors and detection circuits. The detection circuit uses CDC or CAC technology to convert changes into switching signals. This circuit is widely used in consumer electronics, home appliances, industrial control, medical equipment, and automotive fields.