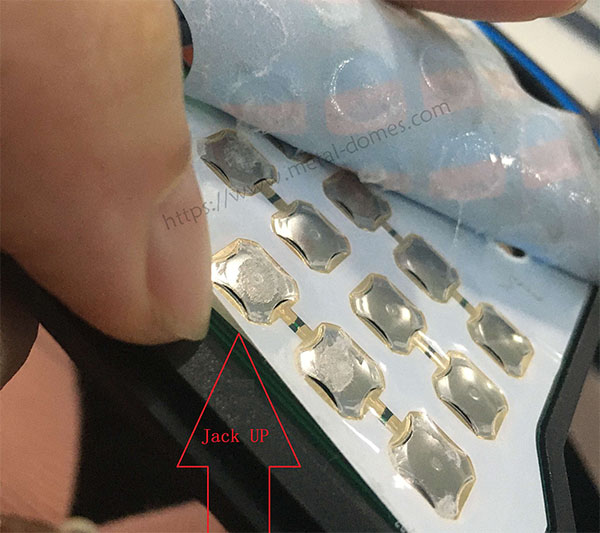

We usually make metal dome array or dome sheet with the standard and normal tape (datasheet of PET adhesive ) . But sometimes we still would hear feedback from some customers that dome array can not be sticked firmly and strongly on PCB (print circuit board) or FPC (Flex PCB), see below photo.

Specific reasons are analyzed as follows, wish it would be helpful for your product design..

- The dome film sheet made with high dome force and stroke (height) as the customer required, lead to the adhesive can’t be pasted well on board, because adhesive layer will be jacked up.

- The adhesive tape area of snap dome array reserved and pasted in the customer’s drawings and specifications is not enough or too little. Generally keep a distance of at least 2.0mm above.

3. The viscosity tolerance of each batch of materials is different. If the material tolerance goes to the lower limit and the above two factors are added, the adhesion may not be very firm.

In general, our metal dome array is unlikely to have such a problem. For these special specifications, we can generally use a more viscous adheisve tape (such as 3M) to solve this problem. We have stronger adhesive materials for some special specifications of the snap dome sheet. However, there is a disadvantage is that it is not easy to tear after sticking, so you should stick to a good position at one time.

Best Technology, your best partner in Asia, is professional for dome sheet and dome switch in China. Please feel free to contact us if you have any question about snap dome.