Many people think that the production of metal dome array is very complicated, in fact it’s not. It’s easy to produce and the cost is not very high. Let me take you through the production process of metal dome array.

As all know, we need to control the production environment of our products well, so before we enter the workshop, we must put on dustproof overcoat, cap and shoe covers, and then be dusted by dust removal system in a closed room.

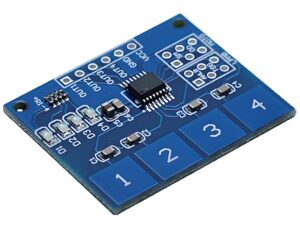

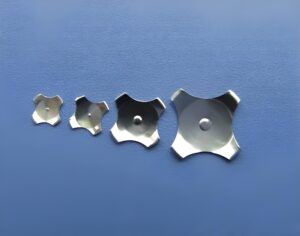

Firstly, we need to do incoming inspection, raw material of PET adheisve with width, thickness, appearance and tension and metal domes switch with life times , force, diameter, height, burr, resistance and appearance, in order to make sure the snaptron domes are all same standard and meet customers’ requirements.

There’re many kinds of PET paper with different colors, such as white, transparent, black, gold, etc. The gold one is most expensive and few customer use it. We often use transparent and white adhesive.

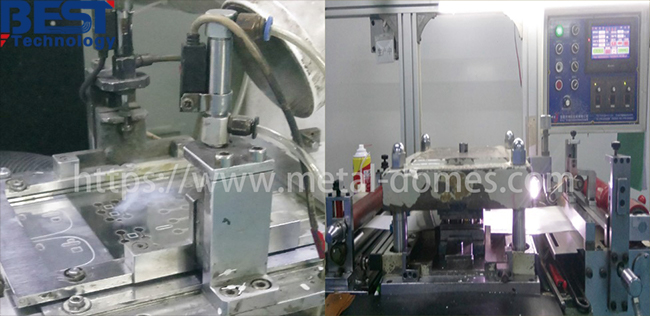

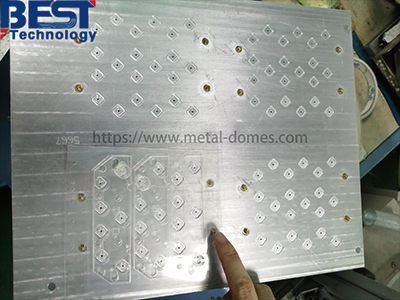

There are two methods to make snap dome array, one method is by laser-cutting, that produce with small qty, a litter longer lead time and higher unit cost, but could save tooling cost; And another method is by machine with tooling, that we can produce big quantities and save manufacturing cost in this way, but the customer need to pay tooling fee.

Now please let me briefly describe the process of how to make dome array by laser cutting. Laser cutting, the temperature of its operation can be 500 degrees. The cost for this manufacture is lower, but the processing charges is a little bit higher.

Firstly, we need to laser cut spacer hole (dome hole)

Second, do first article inspection. Put dome array on assembly Jig, check whether the snap dome hole on assembly Jig and spacer hole on spacer overlap.

Third, we can place other materials on the top of spacer to meet customers’ requirement after spacer production is finished, such place mylar, silver paste, rubber glue or LGF layer. No fingerprints are allowed to be on the spacer, so we’ll gently scrub the spacer by alcohol, and we can have pony-size spacer after machine cutting.

After that, we need to laser cut outline and air channel.

And then, Dimensional measurement for this dome array.

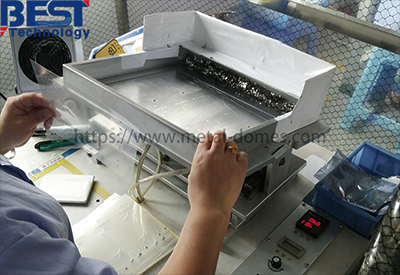

After measure the size of dome array, we’ll assemble the metal domes switch on spacer by fixture.

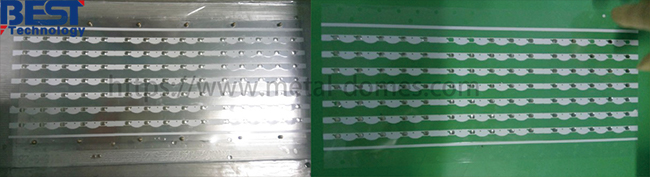

There are dots on fixture, when the fixture is operating, we will put the snaptron domes on it, and the dots will fix the metal domes on them. Put the spacer (sticky side) on the top of Snap domes in dots until all the metal domes switch adhere to it. This is what metal dome array first looks like.

Afeter assemble sanptron dome on array, we need to check whether have double metal domes. Normally we use magnet to check it, will put metal dome array on powerful magnet, if there’s needless Snap dome, it can be attracted away by magnet.

Or use Electrical measuring fixture to check double metal dome, but the customer need to pay the fixture cost by themselves.

After check the doubel metal dome, we’ll settle release paper on metal dome array. Finally we need to do finished product inspection and Pack & Shipping.

Do you know how to make dome array by laser now after reading this article? Please feel free to contact us if you have any question. And I will introduce how to make dome array by machine in next article, please pay attention for us always.

Best Technology is your best partner in Asia, we are always here and waiting for your coming warmly.