SMD, or surface mount device, is a packaging form of electronic components. SMD spring switch is a switch that uses SMD technology to mount metal springs on circuit boards. It uses the elastic deformation of metal springs to achieve circuit switching, and has the characteristics of good tactile feedback, strong durability, and suitability for high-frequency operation. Its compact design and high reliability make it widely used in electronic devices such as membrane switches.

What is SMD electronics?

SMD stands for Surface Mount Device. These are electronic components made to be mounted directly onto the surface of a printed circuit board (PCB). Unlike traditional components with long leads that go through holes, SMDs sit flat on the board.

This design is more compact, which makes electronics smaller, faster, and more efficient. Think of your smartphone, smartwatch, or wireless earbuds—they all rely heavily on SMD components.

Because of their size and power, SMDs have become the go-to choice in consumer tech, medical equipment, military hardware, and industrial control systems. They’re everywhere, silently doing the heavy lifting.

What does SMD mean in electronics?

So, what does SMD mean in electronics exactly? It’s more than just a type of component. It represents a manufacturing approach—Surface Mount Technology (SMT).

This technique replaces the older method known as through-hole technology. Instead of inserting wires through holes, components are placed and soldered directly onto the PCB surface. This shift made products lighter, faster to produce, and more reliable.

In simple terms, the meaning of SMD in electronics points to a more modern, efficient way of building electronic circuits. It’s not just about smaller parts—it’s about smarter design.

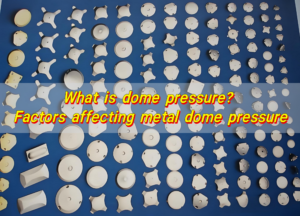

What is an SMD metal dome?

Now let’s zoom into a specific and powerful part—the SMD metal dome. These are tiny, tactile switches made from stainless steel or other flexible metals. They snap when pressed and return when released, giving you that crisp “click” feeling.

They’re used in devices where tactile feedback matters. From remote controls to industrial keypads and medical devices, SMD metal domes bring responsiveness and reliability.

They’re mounted directly on the circuit board using surface mount methods. This adds to their durability while reducing space usage. They’re compact, responsive, and built for high-performance environments.

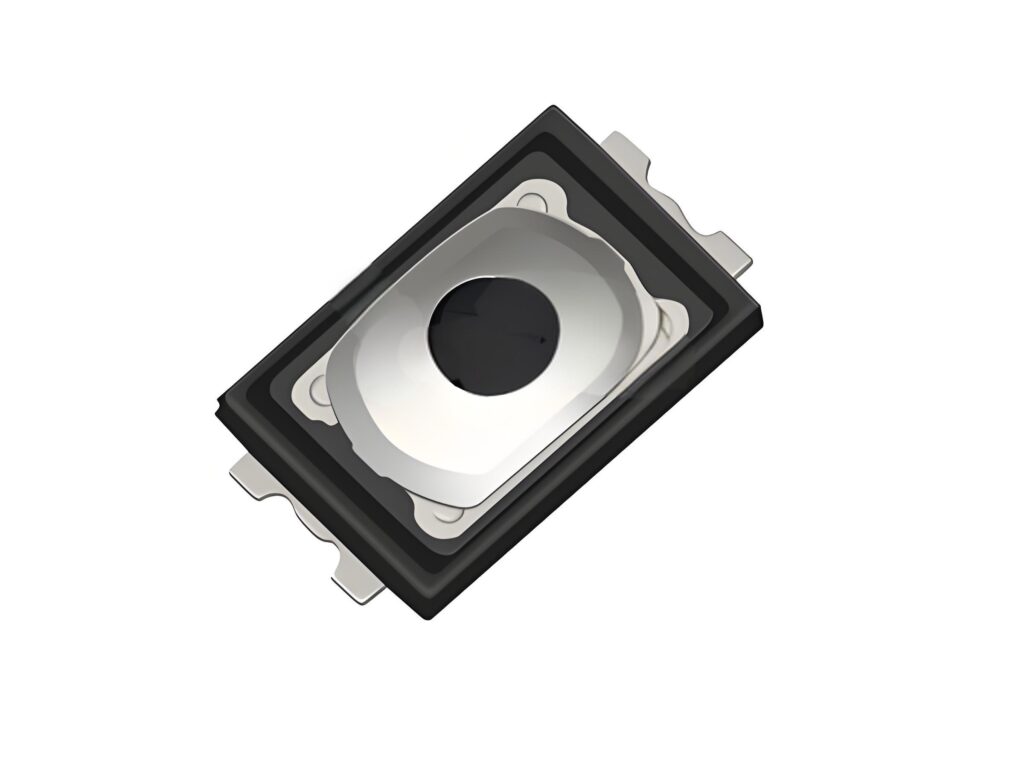

What is an SMD dome switch?

An SMD dome switch is a full switch mechanism that includes the SMD metal dome as the actuation component. It works as a momentary contact switch. When you press it, the dome collapses and completes the circuit. When released, it pops back into shape, breaking the circuit again.

This design is often found in flat panel keypads and control interfaces. They’re loved for their quick reaction time, sharp tactile feedback, and long life cycles. When designed right, an SMD dome switch can last for over a million presses.

How does an SMD metal dome switch work?

The working principle of an SMD metal dome switch is brilliantly simple. Underneath the dome is a printed circuit with contact points. The dome floats slightly above them. When you press it, the dome flexes down and touches the contact points, closing the circuit and triggering the signal.

Once the pressure is gone, the dome springs back to its original shape. The circuit opens again. It’s like a tiny trampoline with electric purpose.

This mechanical action gives strong tactile feedback. It’s fast, reliable, and ideal for repetitive use. Plus, because there are no large moving parts, the switch stays compact and less prone to damage.

What is SMD vs SMT?

These two terms get tossed around a lot, so let’s clear it up.

- SMD: This refers to the actual component—a resistor, capacitor, IC, or dome switch—mounted on the board.

- SMT: This is the technology or process used to place that component on the board.

The SMT is how you spread it perfectly on the cake. Both matter. Together, they make electronics sleek, fast, and powerful.

What does SMT mean in electronics?

SMT, or Surface Mount Technology, revolutionized electronics manufacturing. It’s the method used to solder components directly onto the PCB surface using automated equipment.

Because it makes electronics faster to build, more durable, and cheaper to produce at scale. SMT allows designers to pack more functionality into less space.

Why use SMD components in electronics?

Here’s where it gets exciting. There are powerful reasons why SMD components dominate modern electronics:

- Space Saving: SMD parts are tiny. That means more can fit on a smaller board.

- Lightweight: Less material means lower weight. Ideal for aerospace, automotive, and portable devices.

- High-Speed Assembly: SMT lines can place thousands of SMD components per hour. This boosts production speed and lowers costs.

- Reliability: Shorter leads mean fewer issues with signal interference and vibration. That means more stable, long-lasting performance.

- Design Flexibility: Because of their size, engineers can design more complex circuits in tighter spaces. That allows for smarter, more powerful devices.

SMD metal domes offer a precise, satisfying feel. For medical tools, automotive dashboards, and industrial controls, this tactile feedback isn’t just nice—it’s necessary.

In environments where feedback matters—think emergency buttons, surgical instruments, or factory controls—these switches are game changers. They’re silent, fast, and durable. They give users control they can feel.

They also survive harsh conditions. Dust, moisture, temperature shifts—SMD dome switches power through it all. That’s why industries from aerospace to telecom rely on them. And with SMD metal domes, you don’t just get durability. You get the “click” that makes all the difference.

Conclusion:

SMD stands for Surface Mount Device—tiny, powerful components mounted directly onto circuit boards. It’s part of a broader process called SMT, or Surface Mount Technology, which enables fast, compact, and reliable electronics manufacturing.

SMD metal domes and SMD dome switches offer precise tactile feedback, long life cycles, and unbeatable space-saving benefits.

If you’re designing with tactile control in mind or sourcing quality SMD domes, we’re here to help. Contact us at sales@metal-domes.com