Dome pressure is the reaction force generated when a metal dome is compressed, which is affected by factors such as material properties, shape, thickness and heat treatment process. Different materials have different elastic moduli and strengths; shape and size affect stress distribution; thickness is proportional to stiffness; heat treatment can optimize elasticity and strength. These factors together determine the pressure characteristics of the dome.

What is dome pressure in metal domes?

Dome pressure refers to the amount of force required to collapse or actuate a metal dome in a tactile switch. In simpler terms, it’s the pressure a user feels when they press a button with a metal dome underneath. That resistance and feedback — the familiar “click” — comes from dome pressure.

It’s not just about feel. Dome pressure defines how hard someone needs to press for the switch to respond. If the dome pressure is too low, the button may feel too soft or overly sensitive. If it’s too high, the button could feel stiff or tiring to use.

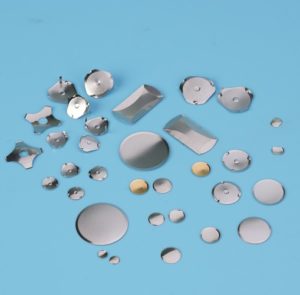

Metal domes come in different shapes — four-leg, triangle, circular, and oblong. Each type creates its own pressure profile. However, dome pressure isn’t just about shape. It’s a dynamic measurement, controlled by the dome’s material, thickness, design, and intended use.

Why does dome pressure matter in switch design?

In switch design, user interaction is everything. The way a button feels under the finger can make or break a product.

Here’s where dome pressure explained becomes crucial. Dome pressure impacts the tactile feedback, responsiveness, and comfort of the switch. A satisfying click can instantly elevate the user experience. A weak or awkward click can frustrate users and lead to performance issues.

Imagine typing on a keyboard with inconsistent feedback. It would be distracting, uncomfortable, and less efficient.

Low dome pressure works well for soft-touch applications — think medical devices or handheld remotes. High dome pressure is better in rugged environments where accidental presses must be avoided.

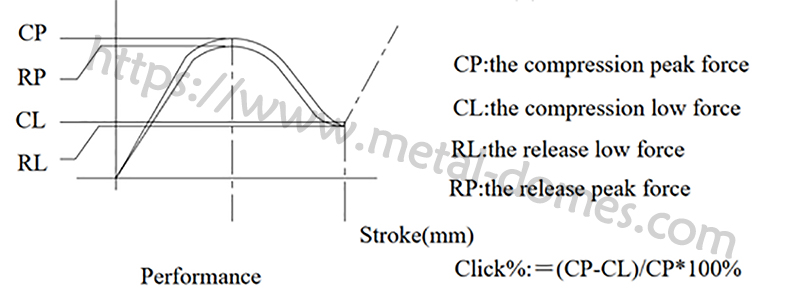

How is metal dome pressure measured?

Measuring dome pressure isn’t as complicated as it sounds, but it must be precise. The most common unit used is grams-force (gf), which quantifies how much force is needed to collapse the dome.

A dome with a pressure of 180gf needs 180 grams of force to activate. Domes typically range from 100gf to over 500gf depending on their intended use.

Special testing machines simulate finger pressure by pressing down on the dome using a stylus or mechanical actuator. This helps engineers record the exact actuation force and the dome’s tactile profile — including pre-travel, snap ratio, and return force.

What affects dome pressure in tactile switches?

Several factors influence dome pressure, and even small changes can lead to big differences in feel and function.

- 1. Dome Shape:

Different shapes distribute force differently. A four-leg dome offers balanced pressure and stable feedback. A triangle dome reacts faster but may feel sharper. Round domes are smooth and even, ideal for general-purpose applications.

- 2. Material Thickness:

Thicker metal domes naturally require more force to actuate. They resist bending more, which boosts dome pressure and durability.

- 3. Diameter and Height:

A larger diameter dome usually has a softer press. A taller dome increases travel distance, affecting snap and feel. Balancing these dimensions helps designers tune dome pressure precisely.

- 4. Raw Material Type:

Different stainless steel grades or plated materials affect elasticity and strength. This impacts not only pressure but also the dome’s lifespan.

- 5. Actuation Area:

Where the dome is pressed matters. Center-pressing yields the true dome pressure. Off-center presses can feel different and may lower the perceived force.

Is higher dome pressure better for durability?

Not always — but in many cases, yes. Domes with higher pressure often last longer because they are made from thicker materials and have more structural resistance. This helps prevent fatigue and deformation over time.

High-pressure domes are common in heavy-duty applications — keypads exposed to dirt, gloves, or rapid-fire use. Think industrial control panels or outdoor equipment. They handle more abuse without failing.

But more pressure doesn’t always mean better. If a user needs to press too hard, it can lead to finger fatigue or missed inputs.

The key is balance. Choose a dome pressure that fits the user’s interaction needs and the device’s environment. That’s where smart design choices shine.

Can dome pressure be customized for different uses?

Absolutely — and this is one of the biggest strengths of metal domes. Customizing dome pressure allows designers to match tactile performance to a specific user need.

For gaming controllers, designers often go for medium pressure with crisp feedback. In medical devices, soft-touch domes with low pressure are preferred for comfort and sensitivity. For machinery and industrial settings, high-pressure domes resist accidental presses and offer strong tactile response.

At Yu An Electronics, we provide dome pressure customization services to fit your exact requirements. Whether you need subtle touches or firm clicks, we’ll tune the pressure to match your goals.

What problems come from incorrect dome pressure?

While dome pressure offers many benefits, incorrect pressure settings can cause real issues.

- Too Low: Users may press the button accidentally, especially in mobile or wearable devices.

- Too High: If users need to apply too much force, they may struggle to operate the device.

- Inconsistency: If dome pressure varies across the keypad, users lose trust in the interface.

These issues are avoidable with proper dome pressure testing and selection. And when pressure is optimized, users feel empowered and connected with the device.

How does dome pressure impact click response?

Click response is what makes tactile switches satisfying. It’s the “snap” moment when the dome collapses and instantly springs back.

Dome pressure directly influences that experience. Higher dome pressure often leads to a sharper, louder click. This gives users confidence that the input was registered. Lower dome pressure produces a quieter, gentler feel — great for silent environments or soft-touch designs.

The responsiveness, sound, and rebound speed all hinge on dome pressure. It also affects timing and control. For tasks that need precision — like operating medical controls or gaming interfaces — optimized click response improves accuracy and speed.

When dome pressure is right, it creates a sensory connection between user and device. It’s not just feedback. It’s satisfaction, clarity, and control at your fingertips.

Conclusion:

Dome pressure is more than a technical specification. It’s a design tool that shapes how people feel when they use your product. The right dome pressure can improve durability, enhance click response, prevent user error, and deliver a truly satisfying tactile experience. So whether you need gentle feedback or a firm press, make dome pressure part of your conversation early. For expert advice or custom dome solutions, contact us at sales@metal-domes.com