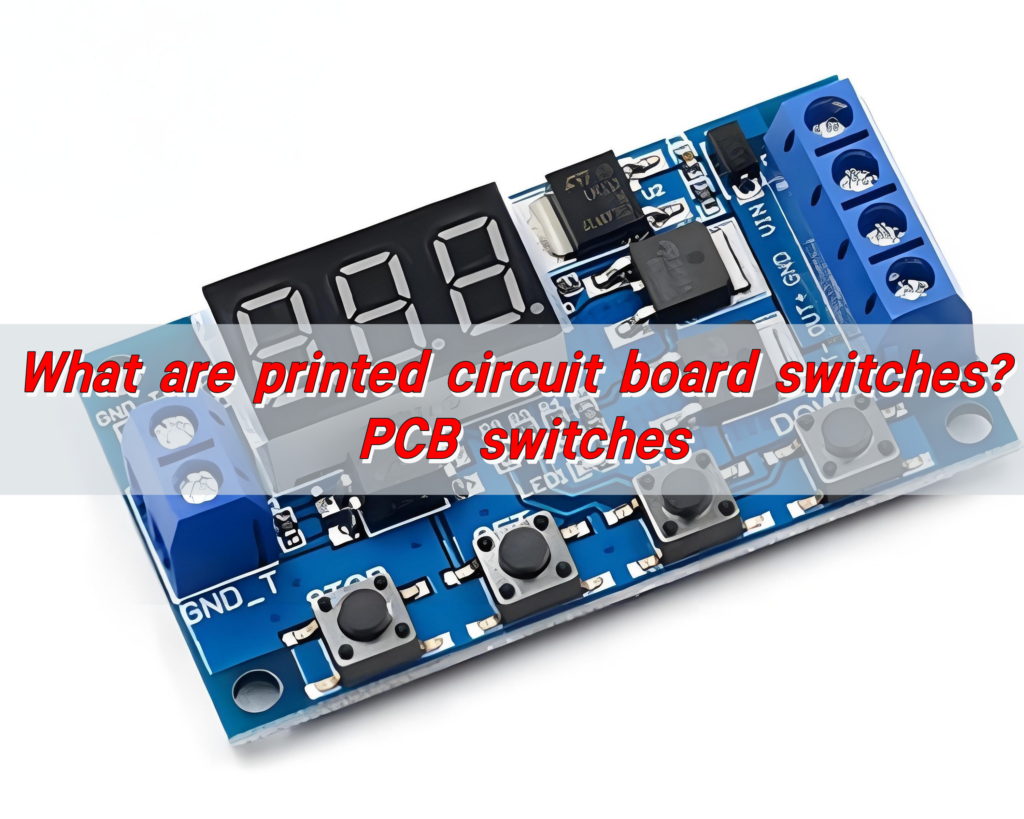

Printed circuit board switches are an electronic component mounted on a printed circuit board to control the opening and closing of a circuit. It is widely used in various electronic devices, including consumer electronics, industrial control, automotive electronics, medical equipment and other fields.

The main function of a circuit board switch is to control the on and off of the circuit to achieve the operation and control of the device. It has the characteristics of miniaturization, integration, high reliability, and long life, and can meet the use requirements of different devices in various environments.

What is a PCB Switch?

PCB switch is a physical switch mounted directly onto a printed circuit board. It’s designed to control current flow by making or breaking the electrical connection. These switches come in many forms—buttons, toggles, domes, or sliders—and are used in everything from mobile phones to medical devices.

In simple terms, it’s the bridge between user interaction and electronic response. When you press a switch on a device, it activates a function—whether it’s turning something on, sending a signal, or selecting a feature.

Most switches are paired with a metal dome, a flexible component that creates tactile feedback when pressed. This clicky, responsive sensation enhances the user experience while also closing the electrical circuit.

PCB switches are compact, durable, and easy to integrate into any design. That’s why they’re everywhere.

What are the Different Types of Switches on a PCB?

Switches come in many styles, each with a unique feel and function.

1. Metal Dome Switches

These use a metal dome under the switch cap. When pressed, the dome collapses and makes contact with the circuit. It then springs back when released. They’re commonly used in printed circuit board keyboards, remote controls, and other devices that require tactile feedback. Metal dome switches are a favorite for durability and crisp response.

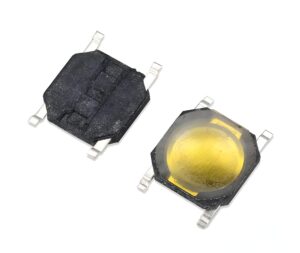

2. Tactile Switches

These are small and low-profile, often used in compact devices. They provide a soft, short travel with a subtle click. Tactile switches are cost-effective and reliable for mass production.

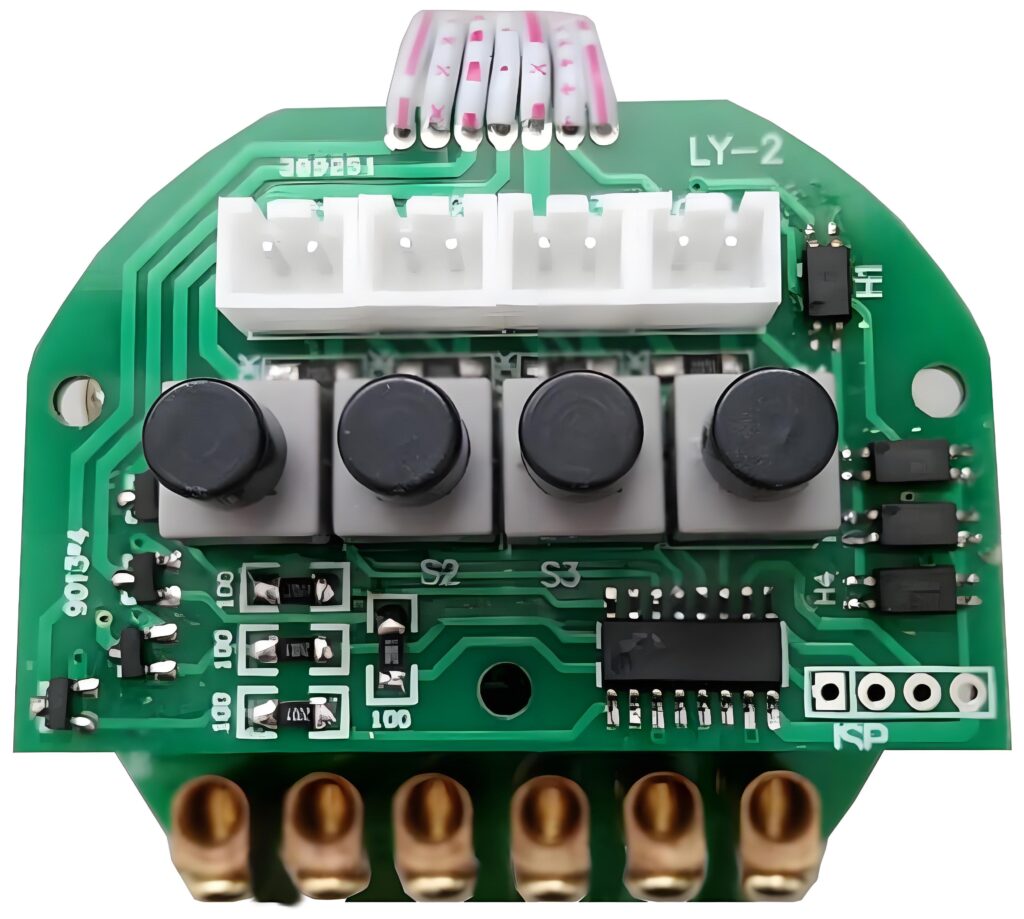

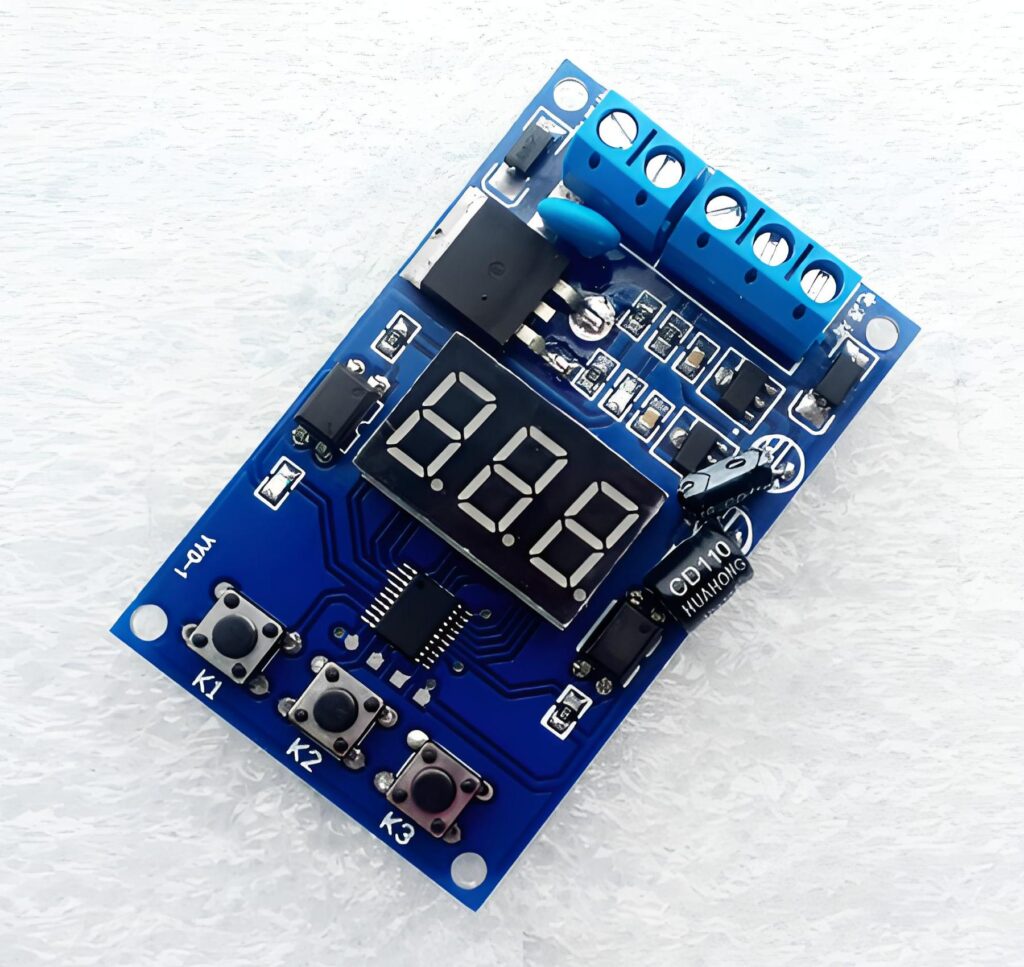

3. Push Button Switches

Also known as momentary switches, they close the circuit only when pressed. These are found in printed circuit board push button switch designs, such as calculators, consumer electronics, or even industrial machines.

4. Toggle and Slide Switches

Used when an on-off mechanism is required, these are common in lighting systems, power tools, or sound systems. A pcb switch on-off function is a typical use case.

5. Rotary Switches

Great for applications that require multiple positions or modes, like old stereo systems or mode selectors.

6. Membrane Switches

These are flat, flexible switches, often used in microwaves or control panels. They can be paired with metal domes for tactile feedback.

Each type brings something different to the table. Choosing depends on application, environment, and user preference.

How Do You Connect a Switch to a PCB?

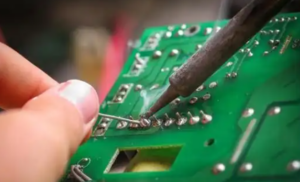

Connecting a switch to a printed circuit board is straightforward but must be done correctly for optimal performance.

First, identify the switch’s pin layout. Some have two pins (simple open-close), others have four or more. Using a printed circuit board schematic diagram, designers place the switch on the PCB layout, ensuring it lines up with the circuit traces.

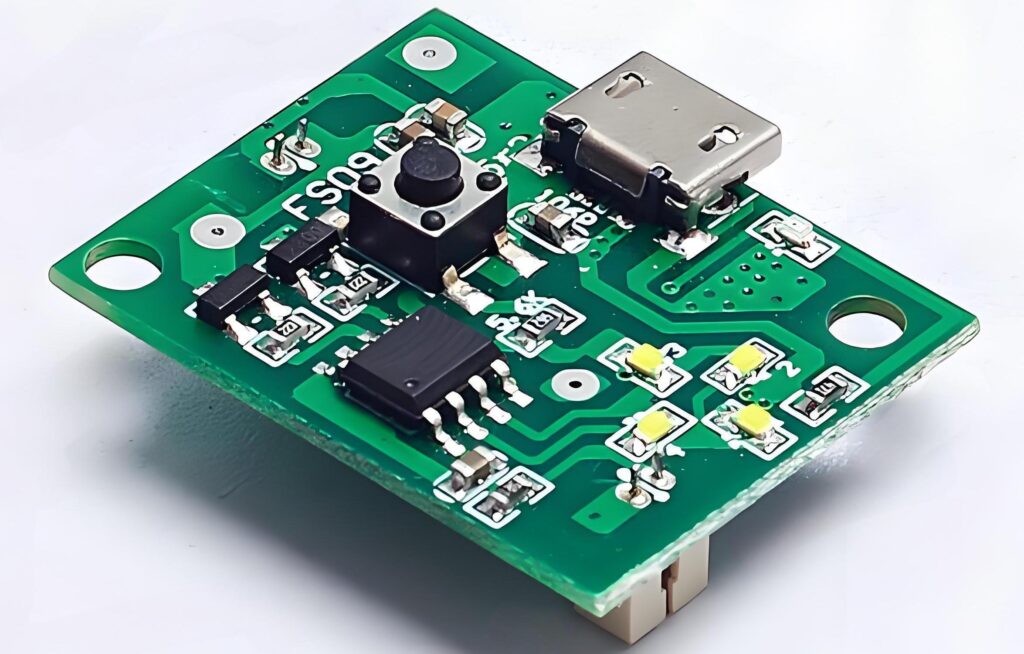

After that, the switch is mounted using either through-hole or surface-mount technology (SMT). Through-hole switches go into drilled holes and are soldered on the opposite side. SMT switches are directly soldered onto the surface. SMT is more common in compact devices.

Then, test the connection. Pressing the switch should close the circuit, and releasing it should break it. Use a multimeter or test jig to confirm functionality.

For printed circuit board kits or DIY projects, these steps are simplified. Many kits come with pre-cut slots and clear printed circuit board symbols to guide placement.

How Does a PCB Switch Work?

Printed circuit board switch works by changing the state of a circuit—either allowing current to pass or blocking it. When you press the switch, a metal contact (like a metal dome) touches the conductive path beneath. This completes the circuit.

Releasing the switch lifts the contact away, breaking the circuit.

Let’s take the circuit board push button switch as an example. It stays open until pressed. Pressing the button brings metal contacts together. Once released, the spring mechanism pushes the contacts apart.

In a printed circuit board keyboard, dozens of tiny switches are laid out in a grid. Each press sends a signal to the processor, telling it which key was pressed. Thanks to fast response and low power use, these switches can handle thousands of presses every day without failure.

What are the Best Switches for Printed Circuit Boards?

The best switches for printed circuit boards depend on the device’s needs. However, a few standouts lead the way.

Metal dome switches are among the most reliable. They combine tactile feedback, low profile, and long life. They’re often used in control panels, medical devices, and industrial applications. The crisp click assures users their action was registered.

Tactile switches are great for low-cost applications with limited space. While they lack strong feedback, they still perform well under high usage.

Printed circuit board button switches—especially those with push or momentary functions—are ideal for interactive devices. They’re used in toys, gadgets, and consumer electronics where fast response matters.

Durability, tactile feel, space, and budget all play a role. For performance and user experience, metal dome switches often come out on top.

How Do You Read PCB Switch Symbols and Diagrams?

Understanding printed circuit board symbols helps you build, repair, or design circuits. Switches usually appear as two lines with a gap, sometimes with a diagonal line or circle. This shows an open circuit.

When the line connects across the gap, it means the switch is closed—current flows.

Look at a printed circuit board schematic diagram and locate the switch symbol. It may be labeled SW1, SW2, etc. Match this with the layout on the board. PCB design software also displays 3D models of the switch for easy placement.

For beginners using printed circuit board kits, diagrams often highlight where to place each switch. The instructions are beginner-friendly, making it easy to follow without deep technical knowledge.

Where are Printed Circuit Board Switches Used?

The beauty of PCB switches is their versatility. You’ll find them in nearly every electronic product.

In consumer electronics, they’re in remote controls, gamepads, and PCB switch keyboards. Their quick response and smooth feel enhance everyday use.

In industrial equipment, metal dome switches are often preferred. They resist wear and tear, work in tough environments, and offer a clear tactile response.

In the medical field, they appear in diagnostic tools and patient monitors. Reliability here is non-negotiable. Switches must work every time.

In automotive, they’re used for controls, seat adjustments, and infotainment systems. Compact size and durability are key here.

You’ll also find them in smart home devices, wearable tech, kitchen appliances, and even toys. As technology becomes more personal and interactive, printed circuit board switches continue to evolve with it.

Conclusion:

Printed circuit board switches might be small, but their impact is massive. They power up devices, enable commands, and create interaction between humans and machines. Whether it’s the snap of a metal dome switch, the press of a printed circuit board push button switch, or the click of a keyboard key, every action starts with a switch.

Want expert help selecting or customizing your PCB switches? We’re here to assist. Reach out anytime at sales@metal-domes.com