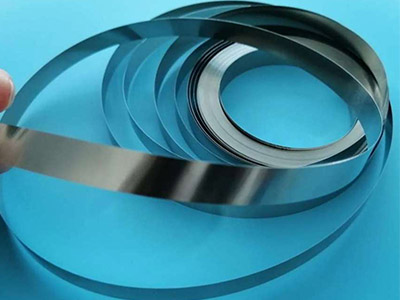

When it comes to snap dome manufacturing, two types of stainless steel stand out—SUS304 and SUS301. These materials are always used as the base material of metal domes. They offer distinct advantages based on their unique properties and chemical compositions. In this article, we will explore the differences between SUS304 and SUS301, helping you understand which is the best fit for your snap dome applications.

What is SUS304 Stainless Steel?

304 stainless steel is a common material in stainless steel, with a density of 7.93 g/cm³; The industry is also known as 18/8 stainless steel, which means containing more than 18% chromium and more than 8% nickel; High temperature resistance 800?, with good processing performance, high toughness characteristics, widely used in industrial and furniture decoration industry and food and medical industry. Among the common marking methods on the market are 06Cr19Ni10 and SUS304, of which 06Cr19Ni10 generally means national standard production, 304 generally means ASTM standard production, and SUS304 means daily standard production.

The most important elements in 304 are Ni and Cr, but they are not limited to these two elements. Specific requirements are specified by product standards. The common judgment situation in the industry believes that as long as the Ni content is greater than 8% and the Cr content is greater than 18%, it can be considered 304 stainless steel.

SUS304 Chemical Composition

The chemical composition of SUS304 is as follows:

- Chromium (Cr): 18%

- Nickel (Ni): 8%

- Carbon (C): 0.08% max

- Manganese (Mn): 2% max

- Silicon (Si): 0.75% max

- Phosphorus (P): 0.045% max

- Sulfur (S): 0.03% max

- Iron (Fe): Balance

SUS304 Mechanical Properties

- Tensile Strength: 520 – 750 MPa

- Yield Strength: 215 MPa (minimum)

- Elongation: 40% (minimum)

- Hardness (Rockwell B): 70 HRB

- Modulus of Elasticity: 193 GPa

- Poisson’s Ratio: 0.29

- Fatigue Strength: 220 MPa (approx.)

- Thermal Expansion: 16.0 × 10?? /°C

- Density: 8.0 g/cm³

- Poisson’s Ratio: 0.27

- Melting Point: 1,140°C – 1,145°C (1,243K – 1,418K)

What Are the Weaknesses of SUS304 Stainless Steel?

While SUS304 is an excellent choice for many applications, it does have some limitations:

- Not as strong as other alloys: SUS304 is not as strong as stainless steel alloys like SUS301, which may be necessary for more demanding snap dome applications.

- Susceptible to chloride-induced stress corrosion cracking: In extreme environments, particularly those involving chlorine or chlorides, SUS304 can experience stress corrosion cracking.

- Lower wear resistance: SUS304 has lower wear resistance compared to certain other grades of stainless steel, which can be a drawback for snap domes exposed to constant friction. Despite these weaknesses, SUS304 remains a top choice for snap dome manufacturing due to its balanced mix of properties.

What is the Life Expectancy of 304 Stainless Steel?

The life expectancy of SUS304 stainless steel depends on several factors, including environmental conditions, the specific application, and how it’s maintained. Generally, in moderate environments, SUS304 can last for decades. Its corrosion resistance helps it withstand oxidation and environmental damage over time. However, the life span can be reduced in harsh, highly corrosive environments or if exposed to extreme physical stress.

For snap dome applications, if maintained well and used in appropriate conditions, SUS304 can perform reliably for many years.

What is SUS301 Stainless Steel?

SUS301 stainless steel is an austenitic stainless steel with high strength and good ductility, mainly used in areas requiring high strength and corrosion resistance. SUS301 and 304 contain low Ni,Cr and high N components, and can achieve high strength through cold working. Compared with ordinary steel, SUS301 has excellent high temperature strength, fatigue strength and corrosion resistance, and can achieve light weight when used in trams.

The material contains higher carbon content than SUS304, contributing to its greater strength. However, this also means that it may be slightly less resistant to corrosion, though it still performs well in many applications.

SUS301 Chemical Composition

SUS301 stainless steel contains:

- Chromium (Cr): 17-19%

- Nickel (Ni): 6-8%

- Carbon (C): 0.15% max

- Manganese (Mn): 2% max

- Silicon (Si): 1% max

- Phosphorus (P): 0.045% max

- Sulfur (S): 0.03% max

- Iron (Fe): Balance

The higher carbon content contributes to the material’s enhanced strength and makes it more suitable for applications where greater mechanical performance is required.

SUS301 Mechanical Properties

- Tensile Strength: 1,000 MPa (minimum)

- Yield Strength: 350 – 650 MPa (depending on heat treatment)

- Elongation: 40% (minimum)

- Hardness (Rockwell B): 90 HRB (high-carbon variants can be harder)

- Modulus of Elasticity: 193 GPa

- Poisson’s Ratio: 0.30

- Fatigue Strength: 320 MPa (approx.)

- Thermal Expansion: 16.5 × 10?? /°C

- Density: 7.9 g/cm³

- Poisson’s Ratio: 0.30

- Melting Point: 1,400°C – 1,450°C (1,673K – 1,723K)

SUS301 Equivalent Materials

SUS301 stainless steel is widely recognized for its excellent mechanical strength, ductility, and corrosion resistance. Equivalent materials to SUS301 exist across various international standards. These materials may have similar chemical compositions, mechanical properties, and applications.

Here are some equivalents to SUS301 stainless steel in different standards:

| Standard | Equivalent Material Name | Notes |

| AISI (USA) | AISI 301 | The direct equivalent to SUS301 in the American Iron and Steel Institute (AISI) system. |

| UNS (USA) | UNS S30100 | Common designation under the Unified Numbering System in the USA. |

| EN (Europe) | X12CrNi17-7 (1.4310) | European equivalent with comparable mechanical properties and applications. |

| DIN (Germany) | 1.4310 | Widely used in Europe, particularly for components requiring high strength. |

| BS (UK) | 301S21 | British Standard equivalent to SUS301 with slight variations in properties. |

| JIS (Japan) | SUS301 | Original Japanese standard designation for this stainless steel grade. |

| ISO (Global) | 301 | Recognized by ISO as part of the international standards for stainless steels. |

| AFNOR (France) | Z12CN17-07 | French designation for an equivalent stainless steel material. |

| GB (China) | 12Cr17Ni7 | Chinese equivalent based on national standards, often used in industrial applications. |

Stainless Steel 301 vs 304 vs 316

| Property | Stainless Steel 301 | Stainless Steel 304 | Stainless Steel 316 |

| Chemical Composition | 17-19% Chromium, 6-8% Nickel, 0.15% Carbon | 18-20% Chromium, 8-10.5% Nickel, 0.08% Carbon | 16-18% Chromium, 10-14% Nickel, 2-3% Molybdenum |

| Tensile Strength | High (up to 1,000 MPa) | Moderate (up to 520 MPa) | Moderate (up to 620 MPa) |

| Corrosion Resistance | Moderate, less resistant than 304 and 316 | Good, especially in mild environments | Excellent, especially in saltwater or marine environments |

| Magnetism | Slightly magnetic when cold worked | Mostly non-magnetic | Mostly non-magnetic |

| Ductility | Good, more rigid compared to 304 | Excellent | Good |

| Formability | Good, though harder to form than 304 | Excellent for forming complex shapes | Good, but requires higher costs and equipment |

| Applications | Spring-like components, automotive, appliances | Food processing, kitchen equipment, medical equipment | Marine environments, chemical processing, medical implants |

| Heat Resistance | Good for temperatures up to 870°C | Good for temperatures up to 870°C | Excellent for temperatures up to 925°C |

At Best Technology, we specialize in providing high-quality snap dome components, manufactured with the best materials, including SUS304 and SUS301, tailored to your specific needs. Whether you require durability, strength, or corrosion resistance, we can help you select the perfect material for your application.