Dome metal is a key component in many electronic devices. It plays a crucial role in creating responsive switches that we often take for granted. From keyboards to touchscreens, these metal domes are everywhere, providing tactile feedback when pressed.

What Is Dome Metal?

Dome metal refers to a small, circular metal piece that is used in the construction of switches. Typically made from stainless steel, it has a unique design that allows it to flex under pressure. When you press a button on a keyboard or a remote control, it’s likely that a metal dome is at work underneath the surface, responding to your touch.

These metal domes are designed to provide tactile feedback. This means when you press a key or switch, you feel a small “click,” confirming the action has been completed. It’s this feedback that makes dome metal switches so popular in various applications.

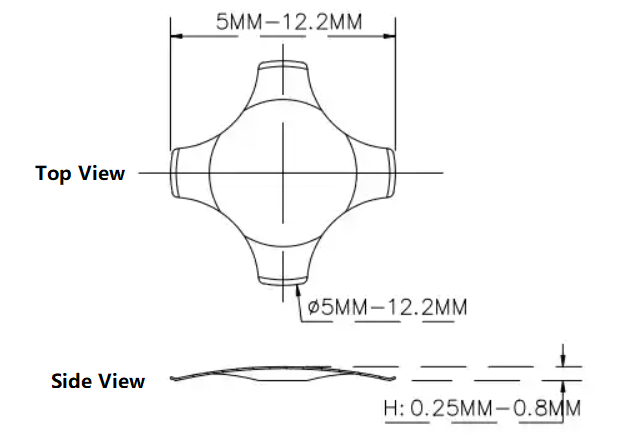

Metal Dome Structure

The metal dome structure is relatively simple but highly effective. The metal dome is shaped like a shallow, inverted bowl, allowing it to compress under pressure. When you press on the surface, the dome collapses, causing a contact to form beneath it. This contact triggers the electrical signal, completing the circuit and registering the action. Below is a top view and side view structure of a metal dome.

Characteristics of Dome Metal

- Material and production process: metal domes are made of ultra-thin (0.05mm-0.1mm thickness) and ultra-thick (generally high hardness) stainless steel 301 or 304 material.

- Thin and small volume: thin product, small volume, easy to install and use.

- ?High hardness: the general hardness is between HV480-550.

- Long life: after special treatment, the life of metal dome can reach more than one million times.

- ?Surface treatment: the metal dome can be nickel plated, silver plated, gold plated and other different surface treatment to meet different needs ?.

- Application: Metal dome is widely used in mobile phones, digital cameras, telephones, mp3 and other digital products. It is mainly used in membrane switch, micro switch, PCB board, and other products.

Metal Dome vs. Metal Dome Array

While individual metal domes are commonly used for single switches, metal dome arrays are essential for applications where multiple presses need to be registered in a small area. Here are some basic differences between the metal dome and metal dome arrays:

1. Metal Dome:

- Single Switch: A metal dome is typically used for a single switch or key press. It’s a small, dome-shaped piece of metal that flexes when pressed, triggering an electrical signal.

- Compact Design: These are designed for one-to-one interaction, often used in devices with a small number of buttons, such as simple calculators, remote controls, or industrial panels with minimal buttons.

- Flexibility: The individual dome is able to compress and return to its original shape with each press, ensuring tactile feedback for the user.

- Applications: Commonly used in devices where individual switches are necessary, such as remote controls, calculators, and some industrial applications.

2. Metal Dome Array:

- Multiple Switches: A metal dome array is essentially a grid of multiple metal domes arranged in a pattern. These arrays are used in keypads or control panels with a large number of buttons, such as in laptops or multifunctional devices.

- Space Efficiency: A metal dome array allows for more switches in a compact space. Instead of having individual domes for each switch, they can be grouped together, saving space and providing a more efficient design.

- Durability: Just like single domes, metal dome arrays are built for durability, capable of withstanding millions of presses.

- Applications: These are found in devices that require high-density switch layouts, such as keyboards, calculators, complex control panels, and some automotive dashboards.

How Long Do Domes Last?

The lifespan of metal domes can vary based on several factors, including usage frequency, pressure, environmental conditions, and the quality of the dome material. However, here’s some general data on how long metal domes last:

- Standard Lifespan: Most high-quality metal domes are designed to last between 5 million to 10 million actuations. This means that with normal use, the metal dome should remain operational and provide the same tactile feedback for millions of presses.

- Premium Lifespan: Some premium domes, especially those used in high-end consumer electronics or industrial applications, are designed to last even longer, often reaching up to 20 million actuations.

- Environmental Factors: Temperature, humidity, and pressure can affect the lifespan. Metal domes exposed to extreme conditions (e.g., high heat or moisture) may experience wear more quickly. However, in normal indoor conditions, they are quite durable.

- Pressure Sensitivity: The amount of pressure applied during each press also affects the longevity. Heavier presses can cause slight deformation over time, while lighter presses tend to preserve the shape and function of the dome for longer.

Overall, high-quality metal domes, if used properly, can provide a reliable and durable solution for long-term applications, with a lifespan that far exceeds many other types of switches.

Dome Metal Applications

Dome metal switches are used in a wide variety of applications. Some of the most common include:

- Keyboards

- Remote Controls

- Calculators

- Automotive Dashboards

- Consumer Electronics like microwaves, coffee machines, etc

- Touch panels

- Industrial control panels

- Medical devices

- Wearable technology

- Toys

- POS systems

- Consumer gadgets

Dome Metal Packaging

When it comes to packaging metal domes for transport and assembly, ensuring their safety and protection is essential. Here are common methods used to package metal domes:

- Tray Packaging:

Metal domes are often arranged in custom-designed trays that keep them securely in place during transit. These trays typically feature individual slots or compartments for each dome, preventing any damage.

- Tape Rolls:

For bulk orders, metal domes may be attached to adhesive tape rolls. This method allows for easy handling and assembly, as the domes are precisely placed and can be quickly transferred to their intended position.

- Vacuum Sealing:

In some cases, metal domes are vacuum-sealed in protective plastic bags to prevent exposure to moisture or dust. This is especially important for high-precision or sensitive components.

- Blister Packs:

Metal domes can be packaged in blister packs, similar to the packaging used for small electronics. These packs help protect the domes from physical damage while allowing easy access for assembly.

- Plastic Bags:

A simple, cost-effective packaging solution involves placing metal domes into static-free plastic bags. These bags help protect the domes from static electricity, which could damage the components.

- Custom Packaging:

For larger quantities or special requirements, manufacturers may use custom-designed packaging solutions. These can include tailored boxes or storage units that optimize space and prevent any movement during transportation.

Best Technology Metal Dome

As a professional metal dome and dome array manufacturer, we are aiming to provide the highest quality and fastest delivery to our customers. At Best Technology, we are not limited to metal dome and dome array, but also membrane switches, special dome arrays, light guide films and surface mount fasteners. We offers various packages with bulk, tube, tape, reel, peel & place and customized packings. If you are interested in dome metal or dome arrays, welcome to e-mail at sales@metal-domes.com.