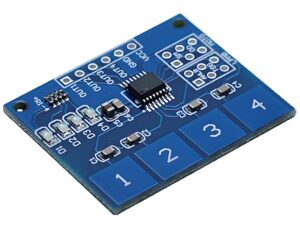

What is a metal switch? A metal switch is a switch device that is mainly made of metal materials or contains metal parts. It is usually composed of a metal shell, a button, and an internal contact mechanism. When the button is pressed, the internal metal dome or contact changes, thereby realizing the conduction or disconnection of the circuit. Push button switches are widely used in various electronic devices, electrical appliances, and industrial control systems.

What is a metal switch?

A metal switch is a device used to control the flow or interruption of current, and is widely used in electrical equipment and circuits. Its core function is to control the working state of electronic equipment by connecting or disconnecting the circuit. Metal switches have the advantages of simple structure, strong durability, reliable on-off, and sensitive operation, so they are widely used in various electronic devices.

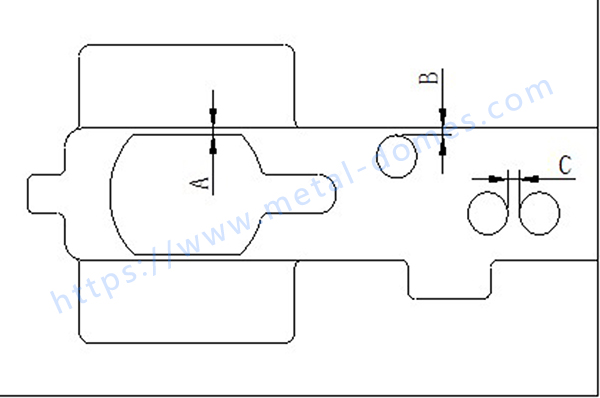

Metal switches usually consist of the following key components:

Contacts: located inside the switch, used to actually connect or disconnect the circuit. The contacts are made of conductive materials, and common materials include copper, silver, etc.

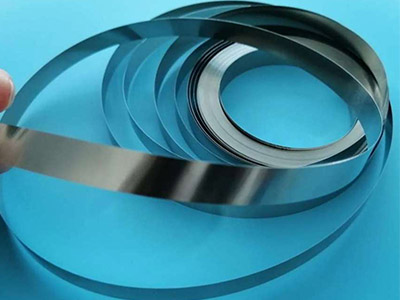

Springs: Ensure that the contacts always maintain a certain contact pressure to ensure the reliability of on-off. The materials of the springs are usually steel, stainless steel, copper, phosphor bronze, etc.

Lever: used to transmit operating force to make the contacts contact and disconnect, usually by manually operating the lever to achieve the control of the metal switch.

Fixed plate: supports the spring and lever, fixed to the shell.

Shell: protects the internal structure, usually made of plastic or metal, with good insulation and corrosion resistance.

Are metal switches safe?

Metal switches are safe under proper use conditions, but you need to pay attention to some safety hazards and correct use methods.

Metal switch panels usually have strong weathering resistance, UV radiation resistance, flame retardancy and other characteristics, and have a long service life, so they are safe under proper use conditions. However, metal switch panels also have some safety hazards in use, mainly including:

Risk of electric shock: If improper installation or use of unqualified electrical appliances and cables, there may be a risk of electric shock, which may even lead to life-threatening.

Overload problem: Using too high a load can cause the electrical components of the switch panel to overheat or even catch fire.

In order to avoid these safety hazards, you need to pay attention to the following points when using metal switch panels:

Correct installation: Select qualified electrical equipment and install it correctly. Do not install electrical appliances where they should not be installed.

Anti-electric shock protection: When installing metal switch panels, attention should be paid to the reliability of grounding, and corresponding safety protection measures should be taken in time when there is a hidden danger of electric shock.

Control load: When using metal switch panels, attention should be paid to controlling the use load to ensure its normal operation.

Strengthen safety measures: During use, attention should also be paid to preventing safety protection issues such as burglary.

In addition, metal switch panels have some advantages, such as elegant and ultra-thin design, good decorative effect, high durability and safety.

What metal is used in switches?

The metals used in switches mainly include copper and silver.

Copper is one of the commonly used metal materials in switches. Copper has good electrical conductivity and certain elasticity, can withstand certain stretching and extrusion, and is suitable for the connection part of the switch. Copper has good electrical conductivity and low loss when transmitting electrical energy, which is suitable for environments with high-frequency switch operations.

Silver is another commonly used metal material, especially in the contact part of the switch. Silver has very good electrical conductivity, which can ensure the fast response and stable operation of the switch. However, silver is soft and easy to oxidize, so in practical applications, silver alloys are usually used to improve its hardness and durability.

Silver alloy is an alloy made by mixing silver with other metals (such as nickel). This alloy not only maintains the good conductivity of silver, but also has higher hardness and better oxidation resistance.

Common silver alloys include silver-nickel alloy and silver-cadmium alloy. Silver-nickel alloy is not easy to oxidize and rust, and is an ideal contact material; while silver-cadmium alloy has good conductivity, but because cadmium is harmful to the human body and easily forms small particles on the contact surface, affecting the conductivity, it is less used.

In general, when choosing the metal used in the switch, factors such as conductivity, hardness, oxidation resistance and cost need to be considered. Copper and silver alloys are widely used in switch manufacturing due to their excellent conductivity and durability.

How does a metal switch work?

The working principle of metal switch is mainly based on the conductive properties of metal conductors, and the on-off control of the circuit is realized through mechanical operation. The structure of metal switch usually includes parts such as contacts, springs, levers, fixing plates and shells.

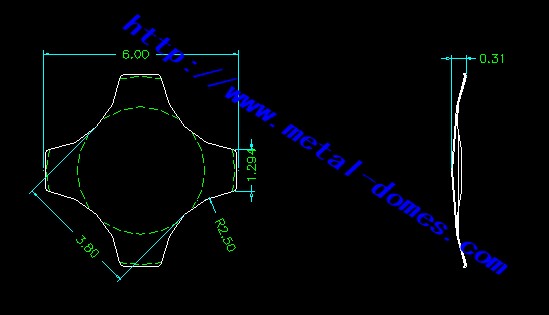

The contact is the most important part of the metal switch. It is made of conductive materials such as copper, silver, gold, etc., and is responsible for realizing the on-off of the circuit. The spring ensures that the contact always maintains a certain contact pressure, the lever is used to transmit the operating force, and the fixed plate is used to support the spring and lever and is fixed on the shell.

What is the best material for a switch?

The best material for a switch is polycarbonate (PC). PC material has excellent heat resistance, flame retardancy and high impact resistance, can withstand arc erosion for a long time, and has very good resistance to ultraviolet rays, and will not change color after long-term use.

In addition, PC material has mature processing technology, comfortable feel, and excellent brightness. It is the preferred material for high-end switch products on the market.

Advantages of PC material

Heat resistance and flame retardancy: PC material has excellent heat resistance and flame retardancy, can remain stable in high temperature environment, is not easy to deform, and can withstand arc erosion for a long time.

Impact resistance: PC material has extremely high impact resistance, and it will not break even if it is hit with a hammer.

UV resistance: PC material has good resistance to ultraviolet rays and will not change color after long-term use.

Mature processing technology: PC material has mature processing technology, comfortable feel, and excellent brightness.

What are the advantages and disadvantages of metal switches?

The advantages of metal switches include:

Good heat dissipation: Metal materials have good thermal conductivity and can effectively dissipate heat, ensuring long-term stable operation of the switch.

Sturdy and durable: The metal shell provides sturdiness, can withstand multiple presses, and has good durability.

Strong anti-interference ability: The metal shell can shield electromagnetic signals, reduce external electromagnetic interference, and improve the reliability of the equipment.

Good waterproof performance: Some metal switches are designed with waterproof functions, suitable for humid or outdoor environments, and improve the durability and safety of the product.

High current carrying capacity: It can carry higher currents and is suitable for a variety of high-power devices.

The disadvantages of metal switches include:

High cost: The material and manufacturing costs of metal switches are relatively high, resulting in a higher overall price.

Difficult installation: Metal switches are relatively heavy and may require special treatment during installation, which increases the difficulty of installation.

Different heat dissipation performance: Metal switches without iron may not have the same heat dissipation performance as switches with iron.

Applications and characteristics of different types of metal materials in switches:

Stainless steel: It has excellent corrosion resistance, oxidation resistance and mechanical strength, and is suitable for applications under various environmental conditions.

Aluminum alloy: low density, good thermal conductivity, suitable for light equipment.

Silicon: has good high temperature resistance, wear resistance and softness, suitable for automobiles and medical equipment.

In short, metal switches, as an important electronic component, play an important role in electronic equipment, industrial control, automotive electronics, medical equipment and other fields. As a special type of metal switch, metal dome switch has the characteristics and advantages of good conductivity, fast response time, reliable contact performance, long life and high durability.