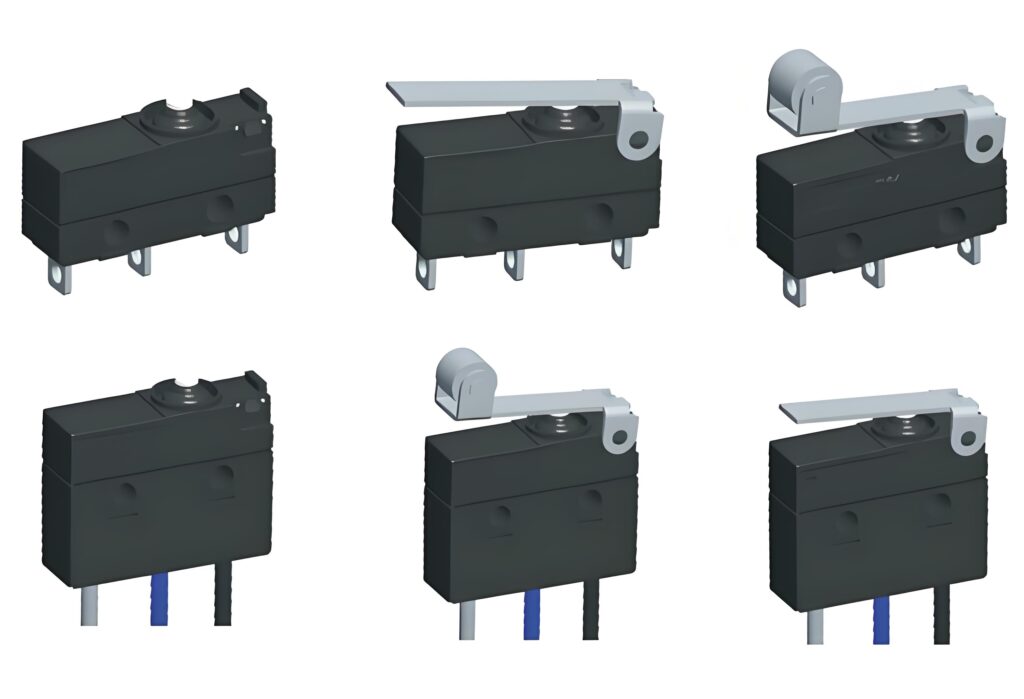

What is a snap switch? A snap switch, also known as a micro switch, is an electronic component that can quickly respond to an action and switch states. It usually consists of an operating part, a contact mechanism, and a housing. The characteristics of a snap switch include fast response, and the response time is usually a few milliseconds or even shorter, which is suitable for scenarios that require high-speed switching.

BEST Technology has rich experience in design and production, specializing in the production of various types of switches, selecting the best quality materials and devoting itself to producing the best products.

What is a snap switch used for?

The main function of a snap switch is to complete the switching or reversing of the motor with a single manual push. A reed mechanism is usually used to ensure fast and stable switching of the circuit.

The working principle of a snap switch is to push the switch body through a manual operating rod, and the reed mechanism quickly moves after being acted upon by an external force to connect or disconnect the circuit. Due to the use of a reed mechanism, the operation feels lighter and the pushing force is small, which can achieve fast and stable circuit switching.

Snap switches are often used in situations where frequent switching is required, such as automated production lines, mechanical processing equipment, etc., due to their fast and stable characteristics. In these scenarios, snap switches can ensure fast response and efficient operation of the equipment.

What is another name for a snap switch?

Another name for a snap switch is a sensitive switch, a snap switch, a momentary switch, a snap-action snap switch, a fast switch, a snap-action snap switch, and a snap-action momentary switch.

These names vary in different fields, such as high-speed switch in shipping, quick-action switch in business, snap-action switch in metallurgy, quick action switch in machinery, etc.

Is a toggle switch a snap switch?

A toggle switch is a snap switch. A toggle switch switches the circuit on or off by toggling the switch handle, thereby achieving the purpose of switching the circuit. It is characterized by flexible slider movement, stable and reliable performance, and is usually used in low-voltage circuits.

There are significant differences between toggle switches and micro switches in structure and scope of use. Toggle switches are usually used in household appliances with relatively low voltages. They are easy to operate and the circuit can be switched freely. Micro switches are mainly used for equipment that requires frequent circuit switching for automatic control and safety protection.

What is a motor snap switch?

A motor snap switch is a switch that can achieve fast and stable switching of the motor through manual operation. It usually adopts a reed mechanism and can complete the switching or reversing of the motor with one manual push. Its structure is relatively simple, mainly consisting of a switch body, a terminal block, a reed mechanism and a manual operating lever. It has a light feel and small pushing force.

Since the snap switch can achieve fast and stable circuit switching, it is usually used in occasions that require frequent switching. For example:

Automated production line: In the automated production line, the snap switch is used to control the start and stop of the equipment to ensure the continuity of the production process.

Mechanical processing equipment: In mechanical processing equipment, the snap switch is used to control the start and stop of the machine tool to improve production efficiency.

Other industrial equipment: In industrial equipment that requires frequent operation, snap switches are also widely used in various control systems.

In summary, the motor snap switch is suitable for occasions that require frequent switching and do not require high control accuracy. Its fast and stable characteristics make it play an important role in industrial automation.

What is the advantage of a snap action switch?

The main advantages of snap action switches include the following aspects:

Quick response and stable switching: snap action switches can complete the switching or reversing of the motor with a single manual push, and usually use a reed mechanism to ensure fast and stable switching of the circuit.

Simple structure and easy operation: The structure of the snap action switch is relatively simple, usually consisting of a switch body, a terminal block, a reed mechanism and a manual operating lever. Its operation feel is relatively light, and the pushing force is small, which is suitable for environments with frequent operations.

High reliability and long life: snap action switches usually have long life and high reliability, and can work stably in harsh environments.

Wide application areas: Due to its fast response and stable switching characteristics, snap action switches are widely used in various automation equipment and industrial control systems.

In summary, snap action switches have become an indispensable component in many automation and industrial control systems due to their fast response, simple structure, high reliability and wide application areas.

The same snap-action switch also has some disadvantages:

Poor contact: The snap-action switch interrupts and connects the circuit by contacting or separating the contacts. If the contacts are in poor contact, it will affect the normal operation of the circuit and may cause the device to fail to start normally or run unstably.

Susceptible to contamination: The snap-action switch is a mechanical switch and is easily affected by external oil, dust, etc. These pollutants will affect the performance and life of the switch.

Wear problem: Long-term or improper operation may cause wear of the sliding contacts, which in turn affects the performance and life of the switch.

Difficulty of installation and maintenance: The installation and maintenance of snap-action switches require certain professional knowledge and skills. Improper operation may cause damage to the equipment or performance degradation.

What is the difference between a snap button and a press button?

The main difference between snap buttons and press buttons lies in their operation methods and application scenarios.

1. Operation method

Snap button: The action is usually triggered by sound or touch. Once triggered, the button will respond quickly and complete the operation.

Press button: The user needs to actively press the button to trigger the action by manual pressure.

2. Application scenarios

Snap-action buttons: often used in situations where quick response is required, such as emergency stop buttons, safety switches, etc., because they can quickly cut off the circuit or start the protection mechanism after being triggered.

Press buttons: suitable for equipment that requires manual confirmation and operation, and users can control the switch or function adjustment of the equipment by manually pressing.

3. Structural features

Snap-action buttons: usually designed as ultra-thin, surface-mounted touch-sensitive, suitable for quick triggering and response.

Press buttons: various designs, including press handles, knobs, push-type, etc., intuitive operation and not easy to trigger by mistake.

4. Working principle

Snap-action buttons: make the circuit conductive or disconnected through sound or touch, suitable for scenarios that require quick response.

Press buttons: manually apply pressure to make the contacts contact and complete the circuit on and off, suitable for operations that require manual confirmation.

In summary, snap-action buttons and press buttons are different in operation mode, application scenarios, structural characteristics and working principles. The choice of which button to use depends on the specific application requirements and usage environment.

In short, the snap-action switch is a switch with the characteristics of fast response, high reliability, multiple types and specifications, and a wide range of applications. It plays an important role in electronic equipment, mechanical devices, industrial automation and other fields.