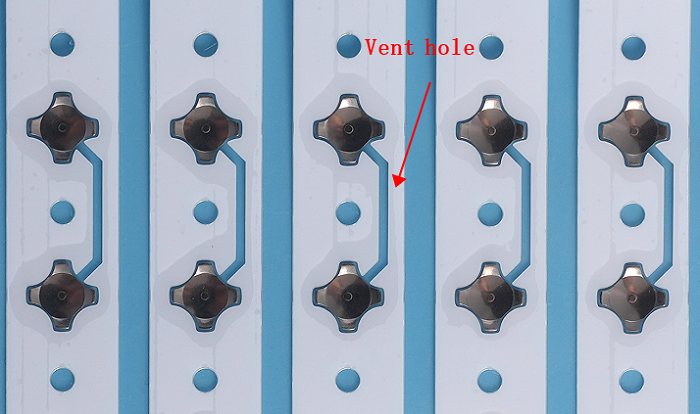

What is the vent hole on the metal dome array? As the name implies, the vent is a hole set on the metal dome array to achieve ventilation. Its main function is to allow air to circulate between different parts of the metal dome array, thereby regulating environmental factors such as internal air pressure, temperature and humidity. In some specific application scenarios, the vent can also prevent static electricity accumulation, remove water vapor and impurities, etc.

BEST Technology uses high-quality metal materials, such as stainless steel, copper alloy, etc., which have good elasticity, conductivity and corrosion resistance, and can ensure the long-term and stable use of the product. From the design stage to the production process, it ensures that the final product fully meets customer expectations.

What is an air vent hole?

In the metal dome array, the vent refers to a hole set in the dome array structure for gas circulation. It is a specially designed channel that allows air or other gases to be exchanged between different areas of the dome array, or between the dome array and the external environment.

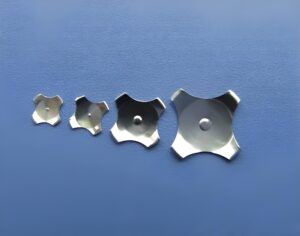

The shapes of vents are various, and the common ones are round, square, rectangular, etc. Circular vents are relatively easy to realize during processing, and their structure is relatively uniformly stressed, and they can better maintain shape stability when pressure changes. Square and rectangular vents may have more advantages in space utilization, especially in matching the shapes of other equipment components.

What is the function of the vent holes on the metal dome array?

During the use of the metal dome array, when the metal dome array is pressed or operated, the air below it will be compressed. The vent hole can discharge the compressed air smoothly to avoid the formation of a local high-pressure area below the metal dome array.

Similarly, when the metal dome array returns to its original state, the external air needs to be replenished to the space below in time. The vent hole can ensure the smooth flow of air, maintain the air pressure balance between the metal dome array and the external environment, ensure that the metal dome array can be elastically reset normally, and enable the key to quickly return to its initial state and prepare for the next operation.

Although the main function of the metal dome array itself is not to dissipate heat, in some electronic devices, the metal dome array is in close contact with heating components such as circuit boards as buttons or connecting parts. The vent hole helps to dissipate heat. When heat is generated inside the device, the flow of air through the vent hole can take away some of the heat and prevent excessive accumulation of heat in and around the metal dome array.

How to arrange the air vent hole?

There are many ways to arrange the vent holes in the metal dome array.

- Center position layout: It is a common method to set the vent hole in the center of the pot piece. When the pot piece is pressed, the pressure is mainly concentrated in the center area, and the vent hole in the center can most effectively discharge the compressed air.

- Edge position layout: The vent hole is arranged at the edge of the pot piece. The edge of the pot piece may be easier to circulate with the outside air. Setting the vent hole here can take advantage of the structural characteristics of the equipment to allow air to flow in and out naturally.

- Evenly distribute multiple vent holes: For some larger pot pieces or application scenarios with high requirements for air pressure balance and air circulation, evenly distribute multiple vent holes. This arrangement method allows the air below the pot piece to be evenly discharged from multiple directions when it is pressed, avoiding excessive local air pressure.

- Arrangement combined with the shape and structure of the shrapnel: Arrange the vent hole according to the shape and internal structural characteristics of the pot piece itself. This method can maximize the function of the vent hole without affecting the mechanical strength and elastic properties of the pot piece.

How to design the air vent hole properly?

There are three ways to make the vent hole on the shrapnel array, including:

1. Design the vent hole between the shrapnel and the gasket

The first way is the most popular and easiest to implement, which is to design it between the metal shrapnel and the gasket. In this way, we can design the vent slot anywhere, and the path can be long or short, depending on the distance between the two metal shrapnel. In this way, the vent slot must be located between the gasket between the two metal shrapnel so that the air can be discharged smoothly.

2. Open a small hole on the top of the ball fixture

If the space between the metal domes is limited, a small hole can be opened on the dome fixture to facilitate air circulation, which can also allow air to be discharged.

3. Punch a hole in the PCB

The shrapnel array or metal shrapnel is almost always assembled with PCB or flexible circuit. So a hole can be punched in the PCB, and in this way, air can flow out of this small hole.

Each of these vent locations has its own advantages and can be selected based on specific design considerations. The choice of vent location affects factors such as trigger force, key feel, and prevents the shrapnel array from sticking or poor responsiveness in the application.

What are the advantages of air vents?

1. Optimize key feel

Air pressure balance: When the pot is pressed, the air below it will be compressed. The vent allows the compressed air to be discharged smoothly, making the pressing process smoother.

Quick reset: After releasing the button, the outside air quickly enters the pot through the vent, helping the pot to quickly return to its original state.

2. Extend service life

Reduce the impact of internal pressure: In the absence of vents, the air below the pot is constantly compressed during repeated pressing of the pot, which will form internal high pressure. The presence of vents effectively avoids the accumulation of this internal pressure, allowing the pot to work under normal air pressure, thereby extending its elastic life.

Prevent water vapor and dust accumulation: In some environments, water vapor and dust can easily enter the device. The vents help maintain air circulation and reduce the retention of water vapor and dust under the pot, thereby reducing the possibility of damage to the pot by these factors.

3. Auxiliary heat dissipation function

Air convection heat dissipation: In electronic devices, the pot is often in contact with heat-generating components such as circuit boards. The vents can promote air convection, so that heat can be dissipated from the pot and its surroundings through the flow of air.

Avoid local overheating: Local overheating may have an adverse effect on the performance of the pot. The vents can prevent the temperature of the pot and its surrounding areas from being too high, and ensure that the pot works within a suitable temperature range.

4. Improve waterproof and dustproof performance

Combined with waterproof breathable membrane: The vents can be used with waterproof breathable membrane. The waterproof breathable membrane allows gas molecules to enter and exit through the vents, but can prevent water molecules and larger dust particles from entering.

What are the disadvantages of air vents?

Without protective measures, the waterproof and dustproof performance may be reduced, and some design and production costs will also be increased.

- Water ingress risk: The presence of vents provides a channel for external liquid to enter the pot. Without proper protection, water can easily enter the pot under the vents.

- Dust ingress risk: Dust can also enter through the vents. The accumulation of dust particles may interfere with the normal operation of the pot, especially in outdoor or industrial environments with a lot of sand and dust.

- Increased design complexity: In order to ensure that the vents can achieve good ventilation functions while minimizing their negative effects, they need to be designed in coordination with other designs, which increases the difficulty and workload of the design.

- Increased production costs: From a manufacturing perspective, the processing of vents requires additional process steps. Whether the vents are made by stamping, drilling or other forming methods, the production cost will increase.

Although the vents on the metal dome array may seem small, they play an important role in fields such as electronic equipment and precision machinery. By adjusting environmental factors such as air pressure, temperature, humidity and static electricity, the vents can improve the performance and reliability of the metal dome array and extend its service life.