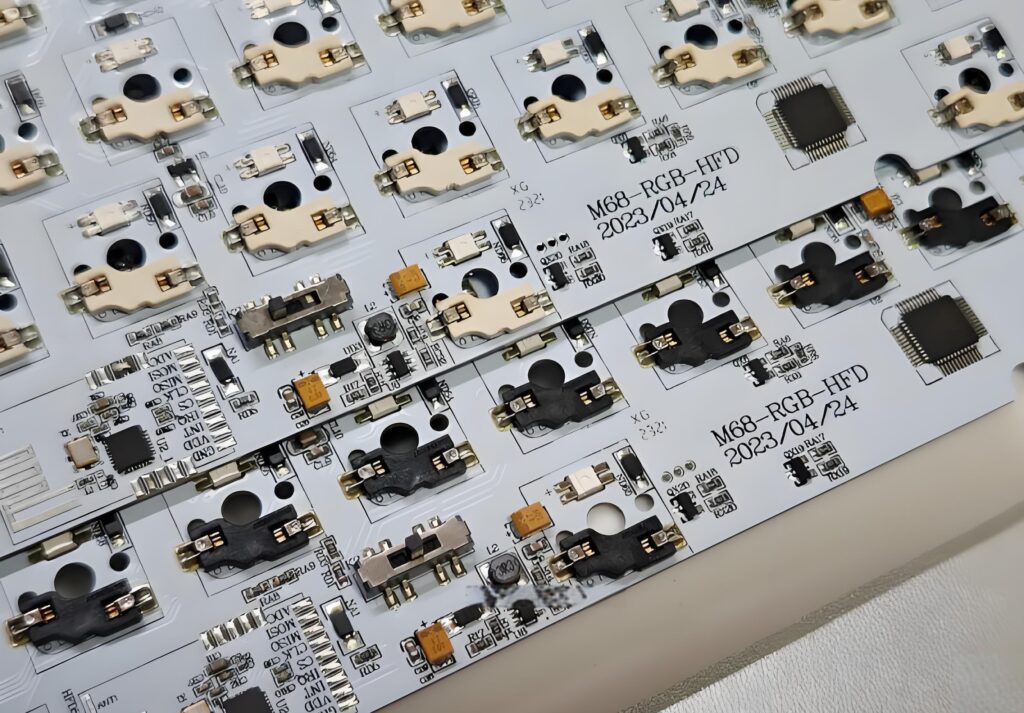

A surface mount switch is an electronic switch mounted on a PCB using surface mount technology. It achieves on-off control of the circuit by directly soldering the switch components on the surface of the PCB. Compared with traditional plug-in switches, surface mount switches have the advantages of small size, light weight, high mounting density, and strong reliability.

BEST Technology has multiple surface mount lines and specializes in manufacturing various types of spring switches, supporting small batch proofing design. The products produced have many advantages, such as good elasticity, fast response speed, and long life.

What does surface mount mean?

Surface mount technology is a technology that directly mounts electronic components with no pins or short pins on the surface of the PCB. This technology solders the components to the pads of the PCB through methods such as dip soldering, thereby realizing the assembly of electronic components.

Surface mount components are usually smaller, thinner, and can achieve higher assembly density, making electronic products smaller and more compact, meeting the requirements of modern electronic products for miniaturization and portability. The welding points are firm, which reduces the failures caused by loose pins, cold soldering and other problems, and improves the reliability and stability of electronic products.

What is surface mount switch?

A surface mount switch is an electronic switch component designed and manufactured based on surface mount technology.

1. Structural features

Miniaturization: Its design is to meet the needs of modern electronic equipment for lightness, thinness and shortness, and the overall size is extremely small.

Contact structure: The key components such as internal contact points and shrapnel are all made of high-precision processing and special materials to ensure good conductivity and elasticity.

2. Working principle

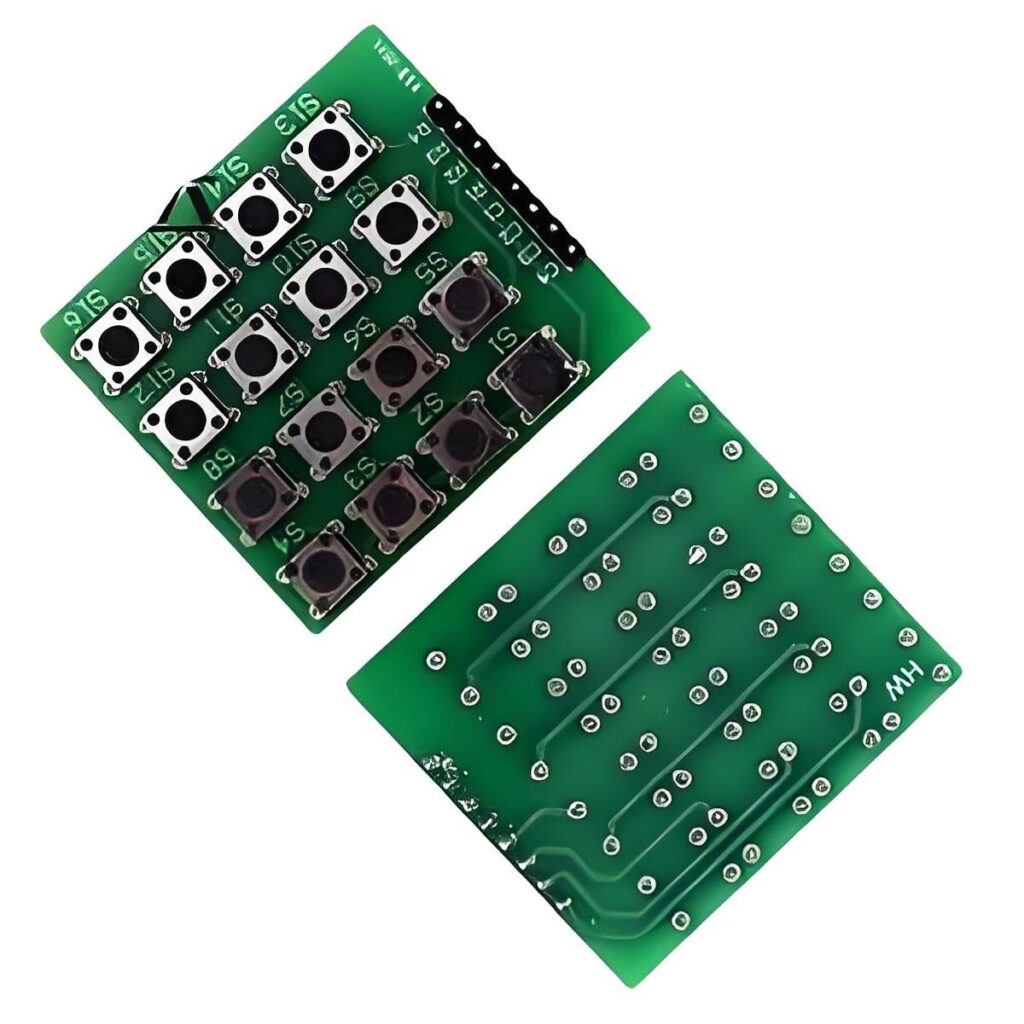

Mechanical button type: When the button is pressed, the shrapnel or contact under the button is deformed, so that the originally disconnected circuit is closed and the current can pass; after releasing the button, the shrapnel relies on its own elasticity to restore its original state, and the circuit is disconnected again.

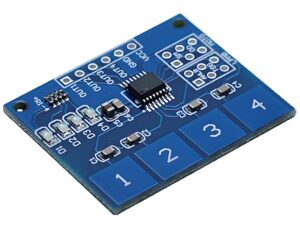

Touch sensing type: Using the capacitance effect of the human body, when the finger touches the surface of the switch, it will change the capacitance value of the touch area, thereby triggering the induction and control logic of the internal circuit to realize the on and off of the circuit.

Sliding type: By sliding components such as sliders or rollers, the connection state of internal contacts is changed to achieve the conduction or disconnection of different circuits.

3. Performance advantages

High precision and high reliability: Advanced technology and strict quality control in the manufacturing process make surface mount switches highly consistent and stable.

Good high-frequency performance: Due to short pins and small parasitic parameters, surface mount switches perform well in high-frequency circuits, with fast signal transmission speed and low loss, which can meet the requirements of modern high-speed electronic equipment for signal transmission.

What is the use of surface type switch?

Surface mount switches have a wide range of applications in many fields, mainly including the following aspects:

Household appliances: Surface type switches are widely used in household appliances, such as refrigerators, washing machines, air conditioners, etc.

Automotive industry: In the automotive industry, surface type switches are often used in smart surfaces of car interiors, such as touch switches.

Electronic communications and: In electronic communications and measuring instruments, surface type switches are used to control the switching function of equipment.

Industrial control: In industrial control and medical equipment, surface switches are used to control the start and stop of equipment. They are simple to operate and highly reliable.

How does surface mount work?

First, prepare surface mount components with pins or electrodes at the bottom or side. Then, solder paste is printed. According to the design of the PCB pad layer, a steel mesh is made so that the solder paste can be applied to the pad through the steel mesh.

Then the SMT machine absorbs the components, places them on the corresponding pads of the PCB after identification, positioning, movement and precise alignment, and places them for misunderstanding detection and correction.

After that, soldering and curing are carried out. Reflow soldering is mostly used. By controlling parameters such as temperature, the solder paste is melted to form solder joints to achieve connection. In some cases, wave soldering is used.

Finally, inspection and testing are carried out, including appearance, solder joint and function inspection to ensure product quality and normal operation of the circuit.

What is an SMD switch?

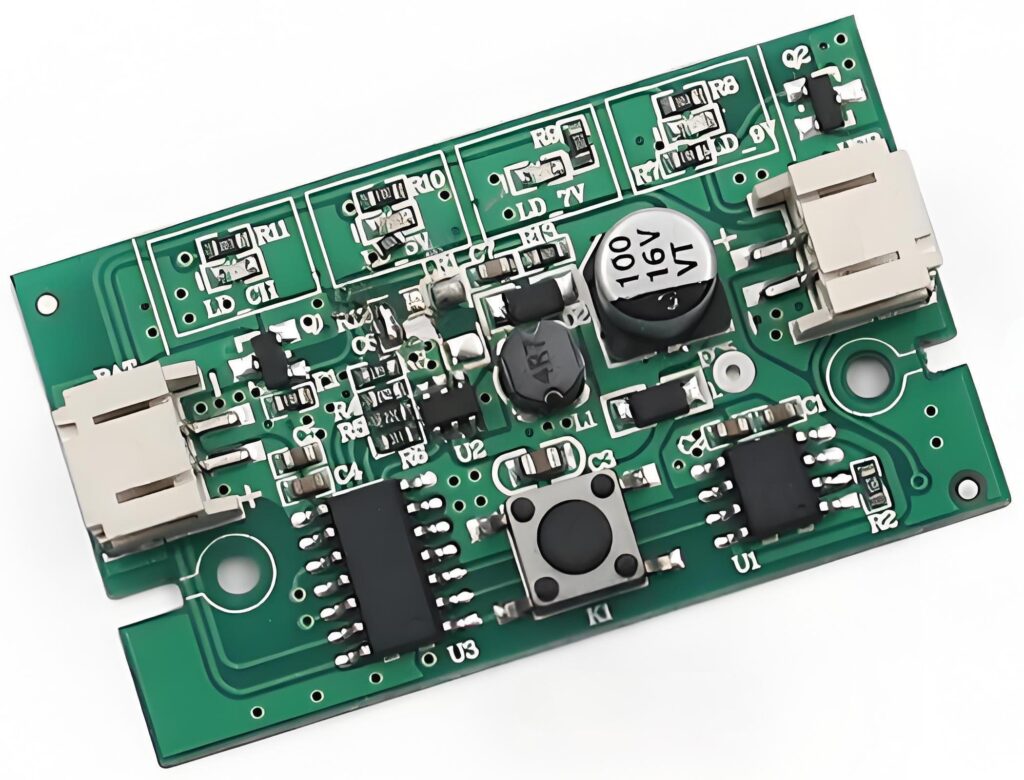

An SMD switch refers to a switch packaged with surface mount technology. SMD switches are characterized by small size, light weight and high reliability, and are widely used in electronic devices such as mobile phones and digital cameras.

The package form of SMD switch is flat, usually directly pasted on the surface of the circuit board through the patch process, without inserting holes on the circuit board. This packaging method makes SMD switch occupy less space in electronic equipment and is suitable for equipment with limited space.

Due to the characteristics of small size, light weight and high reliability of SMD switch, it is widely used in electronic equipment such as mobile phones and digital cameras that require miniaturization and high reliability. These characteristics of SMD switch make it one of the indispensable components in modern electronic equipment.

Why use surface mount technology?

The main reasons for using surface mount technology (SMT) include the following:

Miniaturization and lightweight: SMT technology makes electronic components smaller and lighter, so that electronic products can be designed to be more compact and lightweight.

Production efficiency and automation: The SMT process is highly automated, suitable for large-scale production, can significantly reduce labor costs, and has high production efficiency.

High reliability: The lead length of SMT components is shorter, which reduces inductance and capacitance, improves electrical performance, and reduces failure rate and improves product reliability.

Adapting to the development of modern electronic components: Integrated circuits (ICs), especially large-scale and highly integrated ICs, are widely used in modern electronic devices, so SMT technology has become a necessary assembly method.

Good high-frequency characteristics: SMT components perform well in high-frequency circuits and are suitable for electronic devices that require high performance.

What is surface mount advantages and disadvantages?

Surface mount technology has the following advantages and disadvantages:

Advantages

Miniaturization: Using surface mount technology allows electronic components to be directly mounted on the PCB surface without drilling, greatly reducing the size and space occupied by components, significantly improving assembly density, and making electronic products more miniaturized and thinner.

High performance: Short or no pins on components reduce the delay and parasitic effects of signal transmission, making the high-frequency performance of the circuit better, effectively reducing electromagnetic interference and radio frequency interference, and improving the speed and quality of signal transmission.

High reliability: The solder joint defect rate is low, and the components are tightly connected to the PCB. When subjected to external forces, it is not easy to loosen, fall off or have poor contact, and can adapt to harsh working environments.

High production efficiency: It is easy to realize automated production, which greatly improves production efficiency and shortens production cycle. It is especially suitable for mass production and can meet the needs of rapid market updates.

Cost-effectiveness: In mass production, production efficiency is improved, material waste is reduced, and labor costs are reduced.

Disadvantages

Difficult maintenance: The components are small in size and the pin spacing is narrow. Once problems such as poor welding or component damage occur, it is difficult to locate and operate during rework and repair.

Heat dissipation problem: For some high-power components that generate a lot of heat, surface mounting may not be conducive to heat dissipation, because the components are closely attached to the PCB, and the heat is not easy to dissipate, which may cause the temperature of the components to be too high.

High requirements for surface quality: The quality factors such as the finish and flatness of the PCB surface have a great influence on the welding effect.

In short, the spring switch occupies an important position in the surface mount switch. Its characteristics such as small operating force, good feel, long life, and small size bring many advantages to the surface mount switch. It not only improves the performance and reliability of surface mount switches, meets the high requirements of modern electronic devices for operating experience, but also helps to achieve miniaturization design, making electronic devices lighter and more portable.