Button domes, also known as metal domes or pot pieces, are elastic metal sheets, usually made of metal materials such as stainless steel and copper. It is mainly installed inside the buttons of electronic devices to transmit external forces and realize circuit connection and disconnection.

BEST Technology specializes in the production of various types of metal domes and has rich experience in metal dome manufacturing. We focus on product quality, use high-quality metal materials, and undergo precision processing and strict testing to ensure that the metal domes have good elasticity, conductivity and durability.

What is a dome button?

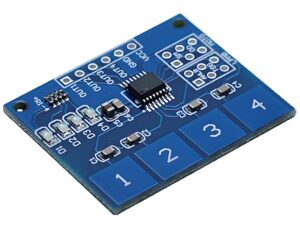

Dome buttons are a common electronic component, usually used in various electronic devices as switches or buttons. The core component of dome buttons is the key dome, also known as metal dome.

The key dome is an important part of the touch switch and is located in the conductive part of the PCB board (mostly above the gold finger on the circuit board). When the button is pressed, the center point of the dome is concave and contacts the circuit on the PCB, thus forming a loop, and the current passes through, so that the entire product can work normally.

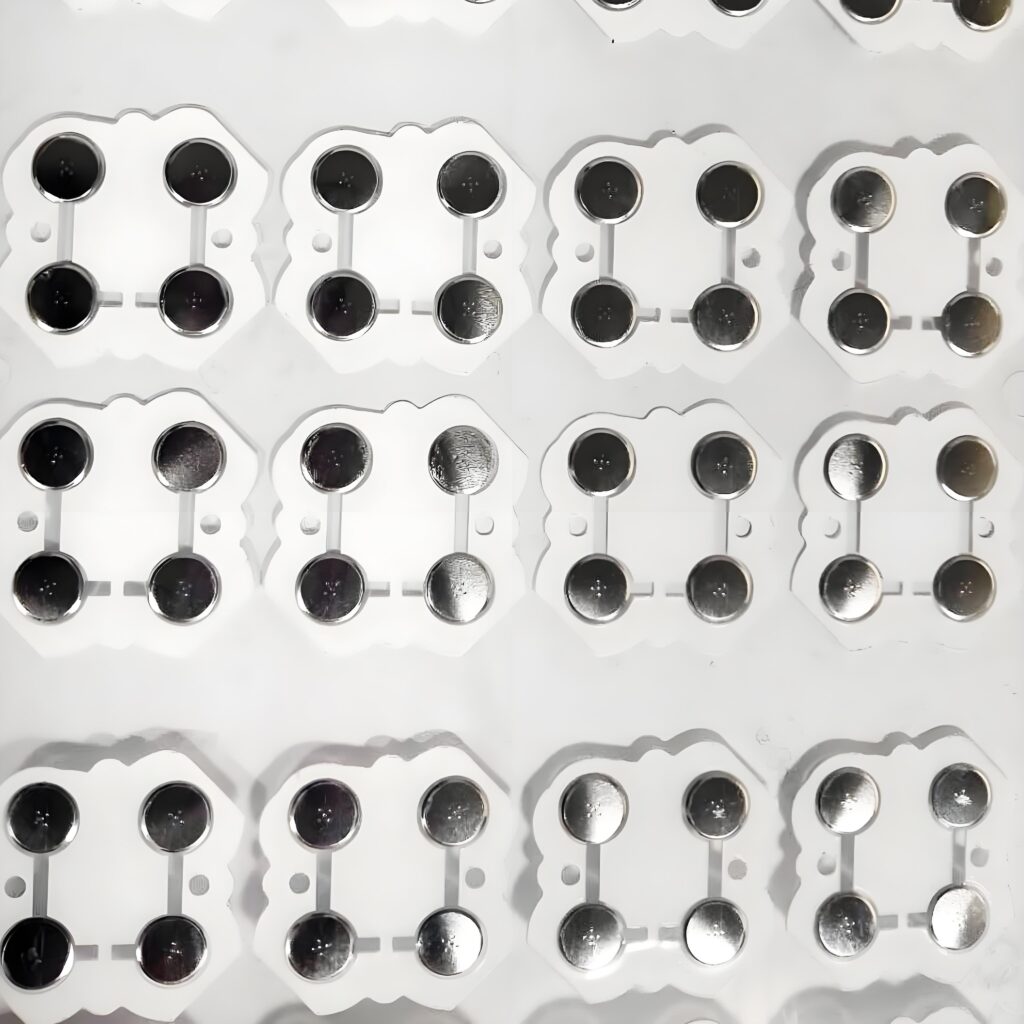

Key dome is usually made of ultra-thin (0.05mm-0.1mm thickness) and ultra-thick (higher hardness) stainless steel 301 or 304 materials. These materials are stamped into shape by a mold and cleaned to be the finished product. If stable resistance and low resistance are required, the surface of the dome needs to be specially treated, such as nickel plating and silver plating.

Key dome is widely used in various electronic devices, especially in membrane switches. Its advantages of strong conductivity, stable rebound and good feel make it the only metal component in membrane switches.

What is the point of a dome?

Metal dome has a wide range of applications in many fields, mainly including the following aspects:

Electronic industry: Metal dome has important applications in the electronics industry. They can be used as connectors on circuit boards to achieve connection and communication between circuit components, simplify the design of circuit boards, improve manufacturing efficiency and reduce production costs.

Mechanical equipment: In mechanical equipment, metal dome is often used to control the tiny mechanism of the torque limiter so that it can be started or stopped accurately.

Medical equipment: In medical equipment, metal dome can be used as a sensor or conductive element to participate in vital sign recording and monitoring.

Other applications: Metal dome is also used in mobile phone cards, mobile phone antennas, membrane switches, contact switches, PCB boards, FPC boards, micro motors, relay switches and other products.

What is a touch dome?

Touch dome is an elastic element used for touch-type key switches, commonly used in touch screens, keyboard switches, rockers and other parts of electronic products. The main characteristics of touch dome are excellent material, good elasticity, long life, and can provide stable feedback and touch during touch operation.

Touch dome is usually made of stainless steel, phosphor copper, beryllium copper and other materials. Stainless steel is widely used because of its corrosion resistance and fatigue resistance. The manufacturing process includes stamping die stretching and stress treatment to ensure its elasticity and toughness.

What is the weakest point of a dome?

The weakest point of a metal dome is usually its contact point or contact surface.

The following defects may occur in the process of using metal dome:

Overpressure: The pressure is uncontrollable, and the load may exceed the normal preset pressure value of the dome, causing the dome to deform.

Excessive crushing: Using sharp objects or nails to scratch the dome.

Contact too large: The contact design is unreasonable, resulting in improper cooperation between the contact and the dome, affecting the normal use of the dome.

Unbalanced contact surface of the dome: The periphery of the dome placement is unbalanced.

Poor contact: Pay attention to the reserved space when installing the dome reasonably.

These defects may cause the elasticity of the metal dome to deteriorate, thereby affecting its use effect and life.

Are button domes tactile?

The button dome itself has no tactile sense, but can provide tactile feedback.

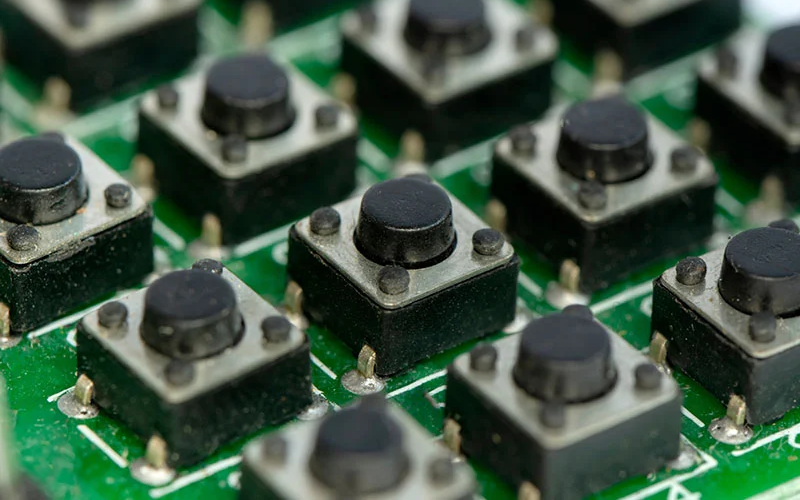

Button dome is usually made of metal or conductive rubber. Its working principle is to deform under the action of external force, thereby changing the on-off state of the circuit.

When the button is pressed, the dome is deformed by the external force and contacts the welding piece or contact, making the circuit conductive; when the button is released, the dome returns to its original state and the circuit is disconnected. This deformation process allows users to feel a clear sense of operation.

Stainless steel domes are often used in applications that require high precision and high stability because of their good stability and resistance to deformation. Phosphor bronze domes are widely used because of their high cost-effectiveness, but they have poor stability and are easily deformed due to temperature changes.

In addition, the structure of the button dome includes parts such as the shell, button, dome, solder or contact, pin, etc., which work together to provide tactile feedback.

What are the characteristics of button domes?

The main characteristics of button domes include:

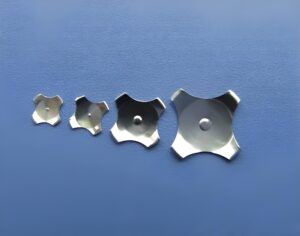

Hardness: The hardness of the dome is generally between 350HV and 550HV to ensure its durability and stability.

Shape: Button domes have a variety of shapes, such as round, triangular, oval, etc. Circular domes are the most commonly used shape, and are widely used in various electronic products because of their short travel and good feel.

Surface treatment: In order to reduce resistance and improve conductivity, the surface of the button dome is usually specially treated, such as nickel plating and silver plating.

Application areas: Button dome is widely used in various electronic products, such as household appliances, computer products, digital products, remote controls, medical equipment, etc.

What are the disadvantages of dome?

The disadvantages of dome mainly include the following aspects:

Resilience problem: The resilience of the dome directly affects its performance and reliability. If the resilience is not good, it may cause problems such as poor contact, functional failure and shortened life.

Durability limitation: Although the durability of the dome has been considered in the design and manufacturing process, it may still be affected by factors such as wear and aging during long-term use, resulting in its performance degradation.

Cost problem: High-quality dome usually has a higher cost. For some users with limited budgets, it may be necessary to weigh the balance between performance and cost.

Dust influence: When dust enters the metal dome without dots, it may cause the defective rate of conduction performance to increase. Although the metal dome with dots can effectively reduce the defective rate of conduction performance, it still needs to be pressed a few more times to make the dust fall off when dust enters.

Over-pressing ring: Using sharp objects or scratching the dome during punching will affect its elasticity.

The contact is too large: unreasonable contact design will affect the normal use of the dome.

Poor contact: too small a gap between the silicone button and the PCB board may lead to poor contact. It is necessary to install the dome reasonably and pay attention to the reserved space.

In short, although the button dome looks small, it plays a vital role in electronic devices. It is made of metal material, with its unique structural characteristics and working principle, it provides electronic devices with good operating feel, fast response speed, long service life and small and light advantages.