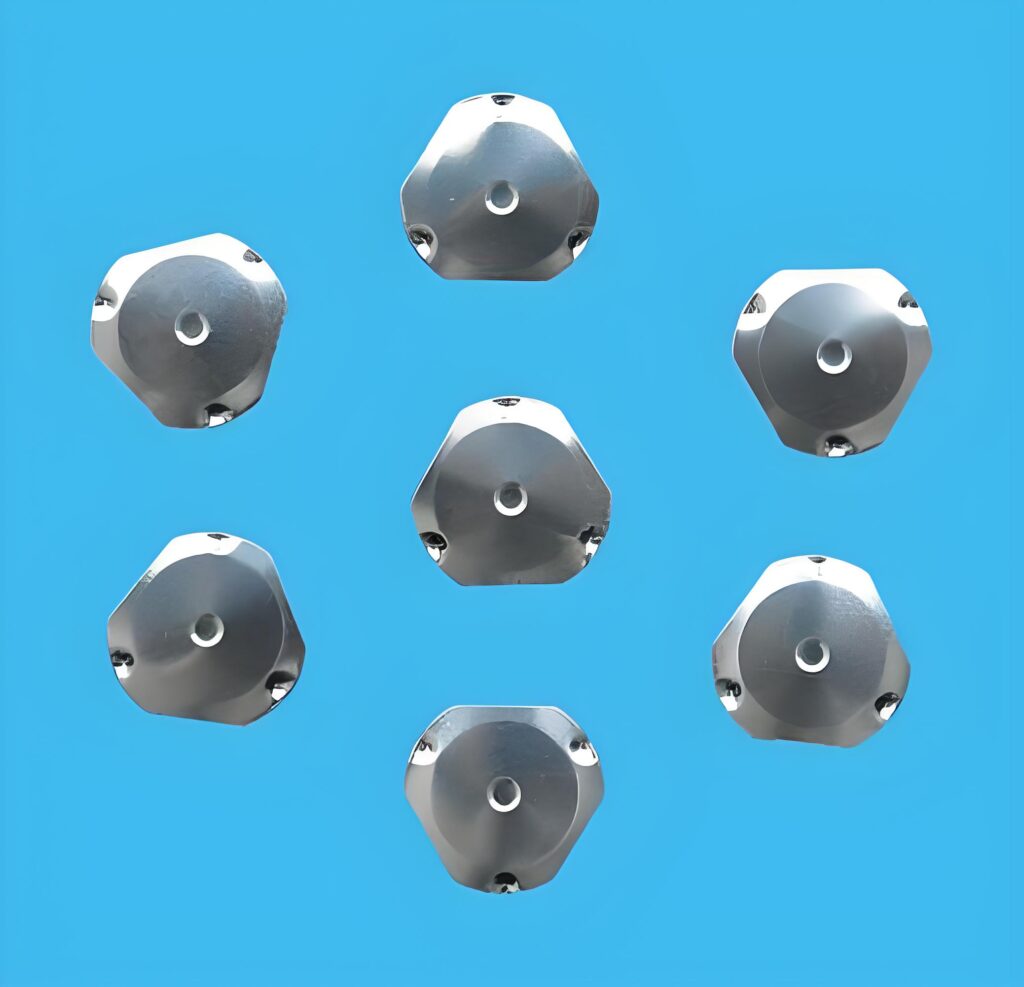

The triangle metal dome is usually made of high-quality metal materials, such as stainless steel, copper alloy, etc. Compared with traditional round or rectangular domes, the triangle metal dome can better maintain its shape and elasticity when subjected to external force, and is not easy to deform, which greatly improves the service life of the product.

What is the metal dome?

The metal dome is a thin sheet element made of metal materials (such as stainless steel 301 or 304). It usually has a specific shape and size, can be deformed when subjected to external force, and quickly return to its original shape after the external force is removed. This feature makes it an ideal choice for realizing multiple functions such as mechanical transmission, electrical connection or disconnection, and pressure sensing.

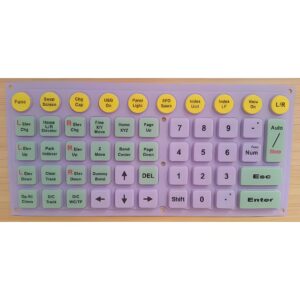

The metal dome is located in the conductive part of the PCB board on the membrane key. When pressed, the center point of the dome is concave and contacts the line on the PCB, thus forming a loop, and the current passes through, so that the entire product can work normally.

Characteristics of metal dome

High elasticity: The metal dome can maintain a stable rebound ability after repeated deformation.

Excellent conductivity: The metal itself has good conductivity, which can quickly conduct the circuit when the key is pressed to achieve signal transmission.

Low contact resistance: The contact resistance between the metal dome and the conductive contact is low, ensuring good circuit conduction and reducing signal loss and energy loss.

Corrosion resistance: By selecting suitable metal materials (such as stainless steel), the metal dome can be used for a long time in harsh environments without being easily corroded.

Strong wear resistance: The metal dome has strong wear resistance during frequent key operations and can withstand long-term use without being easily worn.

High precision: Modern manufacturing processes enable metal domes to achieve extremely high size and shape accuracy.

Good stability: After rigorous design and testing, the metal dome can maintain stable performance under various working conditions.

Strong customizability: Metal domes of different shapes, sizes and elasticity can be designed according to specific application scenarios.

What are the different metal dome shapes?

The main shapes of metal domes include round, cross, triangle and ellipse. These shapes are widely used in electronic devices, such as mobile phone cards, mobile phone antennas, membrane switches, contact switches, PCB boards, FPC boards, medical devices, etc.

Metal dome of different shapes and their application scenarios

Circular metal dome: This is the most commonly used metal dome inside the touch switch. It is particularly suitable for high-end electrical appliances because of its short stroke, good feel, and fast response speed.

Cross-shaped metal dome: Although the sound is clear, due to the large stroke, the time to contact the conductive part during operation is longer and the response speed is slower. It is usually used in special situations.

Triangular metal dome: Suitable for equipment that requires specific shapes and functions, such as some special switches and sensors.

Oval metal dome: Suitable for equipment that requires an elliptical shape, such as some special switches and sensors.

What is the strongest geometric shape dome?

The strongest geometric shape dome is the triangular dome. The triangular dome is structurally stable and can withstand greater pressure and distortion, so it performs well in various applications.

Advantages of triangle metal dome

Stability: The triangle metal dome has higher structural stability, can better resist external pressure and distortion, and is not easy to deform.

Strength: The triangular design enables it to better disperse pressure when subjected to force, thereby improving the overall load-bearing capacity.

Durability: Due to its stable structure, the triangle metal dome is more durable during use and can withstand more frequent use and greater loads.

How are triangle metal dome made?

The production process of triangle metal dome mainly includes the following steps:

Material selection: Select a suitable metal material, such as phosphor bronze, which is usually 0.25mm thick.

Mold design: When designing the mold, it is necessary to retain the bending line of the product, and consider the rebound and give way of the product in the mold design.

Stamping: Use a stamping machine to stamp the metal sheet into the desired shape. During the molding process, it is necessary to ensure that the bending and slider structure of each step can be completed smoothly.

What are the disadvantages of triangle metal dome?

The triangle metal dome has some disadvantages in terms of operating feel, travel and sound effects. Specifically, the triangular metal dome is not as good as the circular metal dome in terms of operating feel, because its shape design makes it feel worse when operating.

In addition, the triangular metal dome has a longer stroke, which means that during operation, the dome takes longer to reach the conductive part, resulting in a slower response speed.

Although the triangular metal dome may be crisper in sound effect, the circular metal dome is more commonly used in touch switches because it has more advantages in operating feel, stroke and response speed.

Where are triangle metal dome used?

Membrane switch: used for the contact in the membrane switch, which forms a loop by pressing to control the on and off of the circuit.

Contact switch: as a key component in the contact switch to realize the switch function.

PCB board and FPC board: used for the connection and switch function of the circuit board.

Medical device: as an important contact switch in medical devices to ensure the normal operation of the equipment.

Why choose BEST Technology‘s metal dome?

1. Quality assurance

Strict control of raw materials: In the selection of raw materials, whether it is precious metal dome for electronic products or ordinary metal dome for mechanical devices, it is ensured that it meets or even exceeds industry standards.

Advanced production technology: Modern production technology is adopted, among which cold stamping technology can achieve high-precision control of the shape of dome, with an accuracy of micron level. At the same time, the use of surface treatment technology can effectively prevent rust and corrosion, and significantly extend the service life of the dome.

Complete quality inspection: A multi-level quality inspection system has been established. Strictly control the quality of materials put into production. During the production process, the dome of each production batch is sampled and the error range is strictly controlled; the hardness of the dome is tested with the help of a hardness tester to ensure that it is suitable for specific application scenarios.

2. Significant price advantage

Effective cost control: Committed to optimizing supply chain management to reduce costs, at the same time, focusing on energy conservation and resource utilization efficiency improvement in the production process, such as the use of energy-saving technology in stamping equipment to effectively reduce electricity costs.

Outstanding cost-effectiveness: Not only is the product price advantageous, but the quality is also excellent. Choosing our metal dome can get a high cost-effectiveness.

3. Excellent customer service

Professional pre-sales consultation: The sales team has high professional quality and rich professional knowledge, and can provide customers with detailed product consulting services, covering dome performance parameters, applicable scenarios, installation suggestions and other contents.

Perfect after-sales guarantee: Provide comprehensive after-sales guarantee services. If customers find product quality problems during use, they will respond as soon as possible. For quality problems not caused by customers, free repair, replacement or refund services are provided.

In short, as an important connection and triggering element, the triangular metal dome plays an indispensable role in modern industry and electronics. With the continuous advancement of science and technology and the continuous changes in market demand, the triangular metal dome is also constantly developing and innovating.