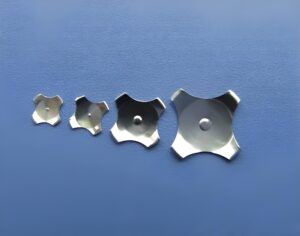

The metal dome is the core of the internal structure of the mechanical button. It is usually a thin sheet of metal, generally made of materials with good elasticity and conductivity, such as stainless steel, copper alloy, etc. The shapes of metal domes are various, the common ones are round, square, triangle, etc., each shape has its specific function and application scenario.

What is a mechanical button?

A mechanical button is an electronic component that closes the circuit through physical contact. It is one of the most common types of buttons, and the circuit is turned on and off by mechanical devices. There are mainly the following types of mechanical buttons:

Self-locking key switch: After pressing the key, the switch is closed, and a mechanical device inside the key hooks the contact, and it remains in a closed state after letting go; press the key again, the mechanical device is unhooked, and the switch is disconnected.

Unlocked key switch: Press to connect, and let go to disconnect. Using an unlocked key switch with a relay or electronic circuit can also achieve circuit self-locking.

Working principle of mechanical button

The mechanical button closes the circuit through physical contact. When the user presses the button, the mechanical device inside the button triggers the circuit to close, and the circuit is disconnected after releasing the button. This design makes the mechanical button have an intuitive operating feel and reliable switching function.

What are the three types of buttons?

There are two main types of push button switches:

Tactile push button switch: Tactile push button switch is one of the most common types of buttons, usually used for the start or stop instructions of the circuit. It realizes the on-off function by the change of the force of the metal dome. Tactile push button switch has the characteristics of good feel and easy operation, and is widely used in home appliances, communication equipment and other fields.

Mechanical self-locking switch: Mechanical self-locking switch realizes the locking function through mechanical structure, ensuring that the button will not automatically bounce up after being pressed until it is manually unlocked. This switch is suitable for scenes that need to maintain the state for a long time, such as switches in some control panels.

What are the different types of mechanical buttons?

There are mainly the following types of mechanical buttons:

Mechanical button: This is the most common type, which closes the circuit through physical contact. The user needs to press the button directly to complete the operation.

Membrane button: Made of flexible material and metal dome, it is usually used for low-cost and thin design.

Push button: The operation speed is slower, but it is not easy to misoperate, and it is suitable for scenes that require precise control.

Touch buttons: have long life, simple operation, waterproof and strong anti-interference ability, suitable for products that require high interactive experience.

Are mechanical buttons better?

Mechanical buttons have obvious advantages in some aspects, but may not be as good as other types of buttons in other aspects.

Advantages of mechanical buttons

Simple structure and reliable use: Mechanical buttons are usually composed of a button and a metal dome, with simple structure and reliable use, suitable for occasions where circuit stability is not required.

Good feel: Mechanical buttons usually have a clear feel, and direct feedback can be obtained even if they are blindly operated, which is very comfortable to use.

Fast trigger speed: The trigger stroke of mechanical buttons is shorter, and the trigger speed is about 35% faster than that of conductive glue buttons, and the time required for triggering will be shortened during use.

Long service life: The average service life of mechanical buttons is up to 5 million times, while that of conductive glue buttons is only 1 million times.

Disadvantages of mechanical buttons

Wear and spark problems: Mechanical buttons change the on and off of the circuit through mechanical touch, and long-term use will cause wear and tear, affecting safety and life.

High cost: Since mechanical buttons have a high trigger speed and service life, the corresponding cost is also high.

Is mechanical better or membrane?

Advantages of mechanical keyboards:

Various and excellent feel: Mechanical keyboards have various shaft designs, each with a different feel, suitable for different usage needs.

Long service life: The life of mechanical keyboard keys can generally reach more than 30 million times, and some high-end products can reach 50 million times.

Strong playability: The various parts of the mechanical keyboard are relatively independent, and users can customize them, even for advanced customization.

Clear feedback: The key feedback of the mechanical keyboard is clear.

Disadvantages of mechanical keyboards:

High price: The production cost of mechanical keyboards is high, and the price is generally more expensive than membrane keyboards.

Heavy weight: Due to the complex structure, mechanical keyboards are usually heavier.

Noisy: The key sounds of mechanical keyboards are loud, which may affect people around.

Advantages of membrane keyboards:

Low price: Membrane keyboards are low-priced, and can be purchased for as little as a dozen yuan.

Lightweight: Membrane keyboards are small in size and light in weight, suitable for portable use.

Moisture-proof and dust-proof: Membrane keyboards have a simple structure and good sealing, suitable for use in harsh environments.

Disadvantages of membrane keyboards:

Poor feel: The key feedback of membrane keyboards is relatively slow, and the feel is not as good as that of mechanical keyboards.

Short life: The key life of membrane keyboards is short, generally only hundreds of thousands to millions of times.

Single function: The function of membrane keyboards is relatively simple, without the diversity and customizability of mechanical keyboards.

Do mechanical buttons last longer than membranes?

Mechanical keyboards are more durable than membrane keyboards. The life of mechanical keyboards is usually longer than that of membrane keyboards. The specific reasons are as follows:

Service life: The key life of mechanical keyboards is generally more than 30 million times. In contrast, the life of membrane keyboards is generally around 3 million times.

Change in feel: After a mechanical keyboard has been used for a long time, the feel of the keys changes little, while the rubber of the membrane keyboard will age and the feel will gradually deteriorate.

Waterproof performance: The waterproof ability of mechanical keyboards is poor, and you need to be more careful when using them, while membrane keyboards are relatively easier to waterproof.

Sound: Mechanical keyboards make a loud sound when in use, while membrane keyboards are quieter.

In summary, mechanical keyboards are superior to membrane keyboards in durability, feel retention, and sound control, but they are more expensive and less waterproof.

What is the disadvantage of mechanical switch?

First, wear is a significant disadvantage of mechanical switches. Since mechanical switches require contact points to send signals, long-term use will cause component wear and eventually lead to failure.

Second, misoperation is also a problem. When the mechanical switch is pressed, the shrapnel will bounce, which may cause accidental clicks.

In addition, slow response time is another disadvantage of mechanical switches. Although mechanical switch technology is mature, occupies a small area, and is low in cost, its response time is slow and is limited by the discharge time of the capacitor.

In short, as the core component of the mechanical button, the metal shrapnel is closely related to the feel, function, quality, and life of the mechanical button from its design, manufacturing to its application in the button. In miniaturized mechanical buttons, the design and manufacturing process of the metal shrapnel poses higher challenges.