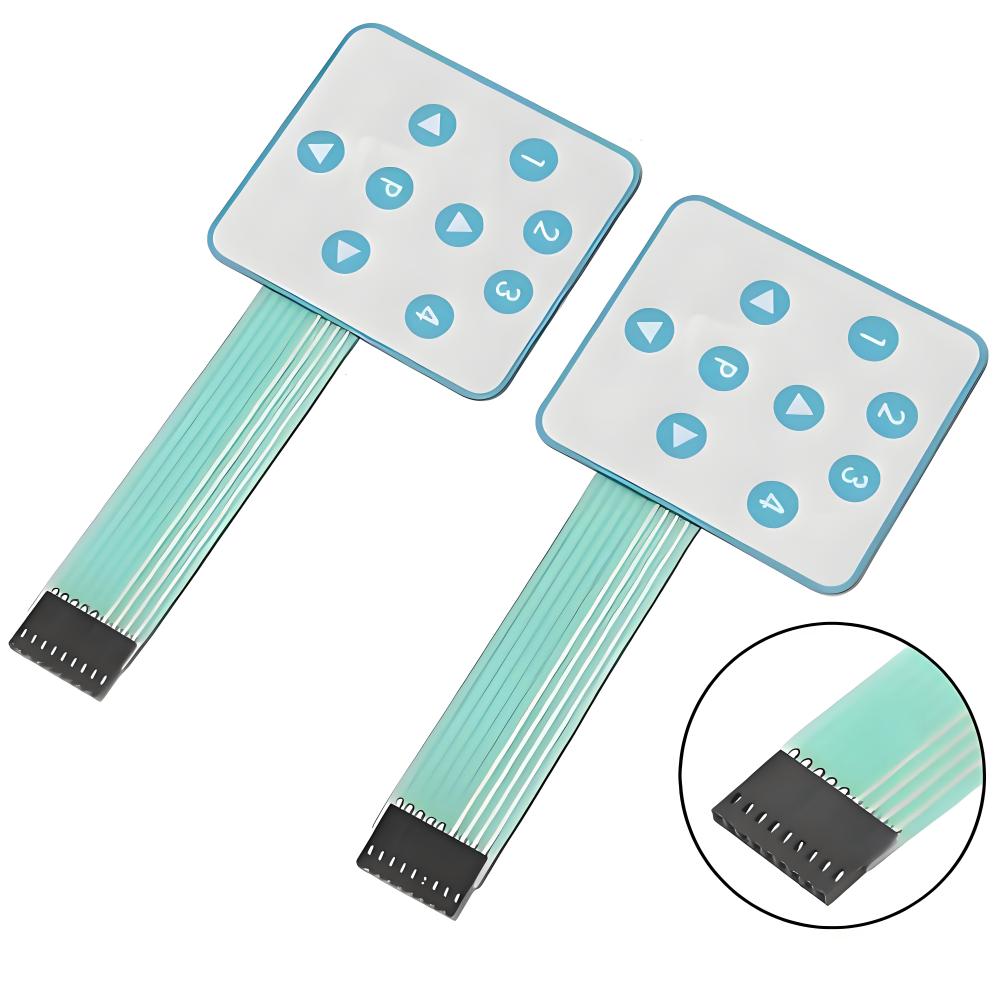

Membrane button are a new type of electronic component that integrates key functions and indicator elements. The working principle of membrane buttons is based on the conductive contact between the upper and lower circuit layers. When the button is pressed, the upper circuit layer of the panel layer contacts the conductive contacts of the lower circuit layer, thus forming a conductive path.

What are membrane buttons?

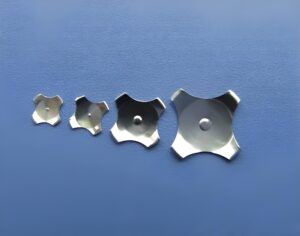

Membrane buttons, also known as metal dome array, are a PET sheet with contacts, which are usually used as switches on circuit boards such as PCB or FPC. It plays an important role as a tactile switch between the user and the instrument.

The basic structure of a membrane button includes a PET sheet with contacts. When the sheet is pressed by external force, the center point of the contact will be concave and contact the circuit on the PCB, thus forming a loop, and the current passes through, so that the entire product can work normally.

The design of the membrane button largely determines the feel and characteristics of the button. The thickness of the membrane is usually between 0.125-0.2 mm. Too thin will lead to weak rebound and insensitive contact separation; too thick will be slow to respond and increase the operating force.

How do rubber membrane buttons work?

When not pressed by external force, the membrane button is in normal state. At this time, the contact between the upper circuit and the lower circuit of the membrane switch is disconnected, the current cannot pass, and the circuit is in an open circuit state.

When the panel of the membrane button is pressed by external force, the panel will transfer the pressure to the upper circuit layer, and the contact of the upper circuit will deform downward, so that the upper circuit and the lower circuit are connected through the contact, so that the circuit is turned on

After the circuit is turned on, the current can pass through the circuit of the membrane button, and the turned-on circuit will transmit an electrical signal to the externally connected instrument (substrate)

After receiving this signal, the external instrument will perform corresponding operations according to the pre-set program or logic, thereby realizing the corresponding function of the membrane button.

When the finger releases the pressure on the membrane button, the external force applied to the panel disappears. The contact of the upper circuit will rebound under the elasticity of the membrane material, and the circuit is disconnected. At this time, the membrane button returns to the normal open circuit state, waiting for the next press operation.

How good are membrane switches?

Membrane switches have the following advantages:

Good sealing: The overall structure of membrane switches is sealed and not easy to oxidize. It has good waterproof, dustproof and anti-corrosion properties and is suitable for use in various harsh environments.

Good durability: The service life of membrane switches can generally reach more than one million times. The rationality of material selection enables it to withstand high-frequency use without deformation.

Light weight and small size: The membrane switch can be arranged and combined into a membrane keyboard in design. The sealed sheet structure composed of multiple layers of membrane makes it small in size, light in weight, and easy to carry and install.

Rich colors: The membrane switch has a beautiful appearance and rich colors. The decorative effect reflects the comprehensive characteristics of material beauty, decorative beauty, and craftsmanship beauty.

Reduced supporting costs: The installation of membrane switches is adhesive, which saves labor and materials and reduces the supporting costs of the whole machine.

What are the disadvantages of membrane buttons?

The main disadvantages of membrane buttons include:

No operating feel: The membrane button has no obvious physical feedback during operation, which is easy to cause misoperation or repeated operation, affecting the user experience.

Low finished product qualification rate: The finished product qualification rate of membrane buttons is low, and the requirements for design and manufacturing are high, which is prone to quality problems.

Sensitive to electromagnetic interference: Membrane buttons are easily affected by surrounding electromagnetic interference, which affects their stability and reliability.

High design requirements: The design and manufacturing of membrane buttons require a high level of technology and precision craftsmanship, which increases costs and difficulties.

What are the three types of buttons?

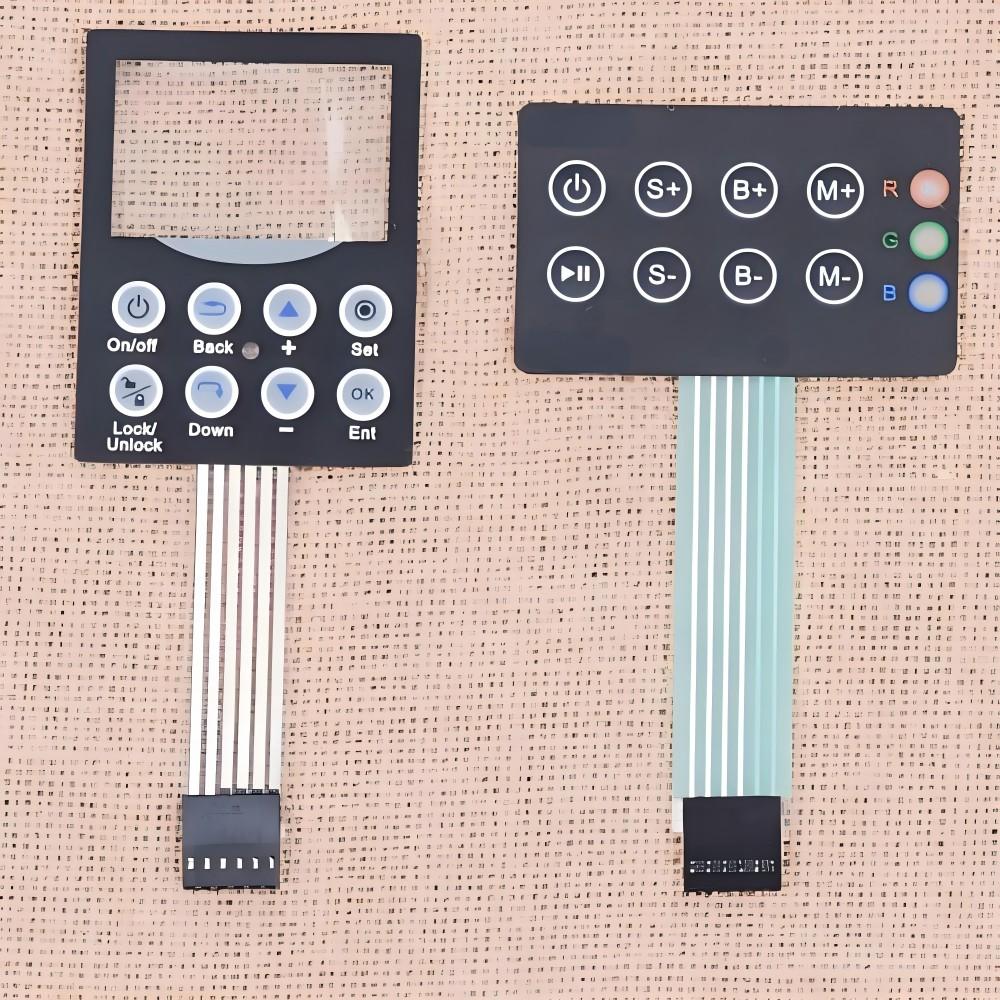

There are three main types of buttons: mechanical buttons, membrane buttons, and touch buttons.

Mechanical buttons: This is the most common type of button, which closes the circuit through physical contact. This type of button has clear tactile feedback and is suitable for scenarios that require clear operational feedback.

Membrane buttons: Made of flexible materials and conductive inks, they are usually used for low-cost and thin designs. This type of button has a simple structure and is suitable for mass production, but due to the lack of physical feedback, the user experience may not be as good as mechanical buttons.

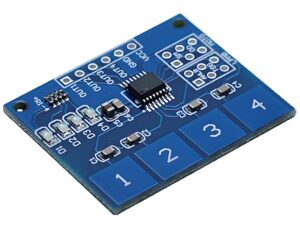

Touch buttons: There are no physical moving parts, and touch is detected by capacitance, resistance or other sensor technologies. This type of button is suitable for occasions that require a simple appearance and space saving.

These different types of buttons have their own advantages and disadvantages and are suitable for different application scenarios. Mechanical buttons provide clear operational feedback, but are more expensive; membrane buttons are cheaper but lack physical feedback; touch buttons are suitable for modern electronic devices, but may be more sensitive to environmental changes.

What are the applications of membrane buttons?

Electronic communications and electronic measuring instruments: Membrane button switches are used in these fields to control various functions, such as adjusting volume and switching channels.

Industrial control: In industrial automation systems, membrane button switches are used to control the operation and settings of machines.

Medical equipment: In medical equipment, membrane button switches are used to control the operation of various medical instruments to ensure the reliability and safety of the equipment.

Automotive industry: In automobiles, membrane button switches are used to control audio, air conditioning and other equipment, providing a convenient operating experience.

Smart toys: In smart toys, membrane button switches are used to control game functions and interactive experiences, increasing the fun and interactivity of toys.

Household appliances: In household appliances, membrane button switches are used to control various functions, such as turning on and off the machine, adjusting the temperature, etc., providing a user-friendly operating interface.

Membrane buttons are characterized by being light, thin, compact, beautiful in appearance, good in operating feel, high in reliability and low in cost. Widely used in electronic equipment, industrial control, medical equipment and other fields. Driven by modern technology, membrane buttons continue to develop, and their importance in electronic products and various industries is becoming increasingly prominent.