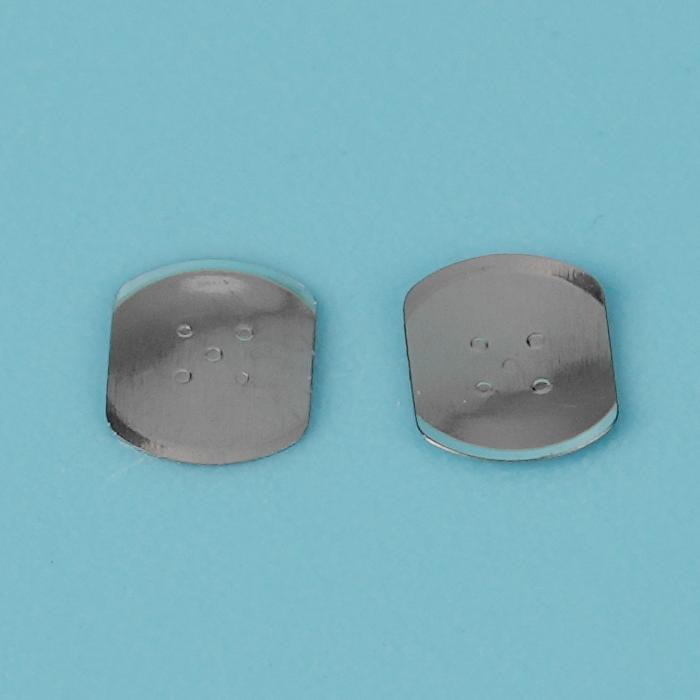

The core component of metal switches is metal dome, which is usually made of materials with good elasticity and conductivity such as stainless steel and copper. When external force acts on the switch, the metal dome will deform, thereby triggering the switch action. The shape and size of the metal switch are carefully designed to produce appropriate deformation under different external forces to ensure that the switch is triggered accurately.

Are metal switches safe?

Metal dome switches are safe, but you need to pay attention to some potential risks. Metal dome switches are safe under normal use. They are widely used in various electronic devices, including membrane switches, contact switches, PCB boards, etc.

The working principle of metal dome switches is to deform the dome by pressing, contact the conductive part, form a circuit, and thus control the on and off of the circuit. When the button is released, the dome returns to its original state and disconnects the circuit. This design makes the metal dome switch have a clear feel and reliability.

However, metal dome switches also have some safety hazards. First of all, metal is an electrical conductor. If anti-electric shock measures are not taken into account in the design, there may be safety risks. Secondly, after long-term use, the metal of the metal dome switch may oxidize, resulting in poor contact or short circuit. In addition, if the quality of the metal dome is not up to standard, it may also cause the switch to malfunction or damage.

To ensure the safe use of metal dome switches, the following measures can be taken: First, choose a metal dome switch product with reliable quality and ensure that it has passed the relevant safety certification. Second, during use, be careful to avoid excessive squeezing or impacting the switch to reduce the possibility of deformation of the dome.

Why are the switches not made of metal?

The role of metal in the circuit is mainly to conduct electricity, while the function of the switch is to control the on and off of the circuit. Metals such as copper or aluminum can conduct electricity well, but are not suitable as switch materials because they cannot effectively cut off the current. The switch requires a material that can switch between the “on” and “off” states, and metal cannot achieve this function.

In addition to plastics, other materials such as glass and metal are also used in switch design. Glass materials are usually used for exterior decoration, while metal materials such as stainless steel or aluminum alloys are used to enhance the durability and aesthetics of the switch.

Why are plastic switches safer?

Plastic switches are safer because of their good insulation, low risk of electric shock and good protection. The shell of a plastic switch is usually made of plastic material, which has high insulation performance and can effectively prevent current leakage and electric shock accidents.

Compared with metal materials, plastic switches have more advantages in safety, because metal materials such as stainless steel are prone to electric shock accidents and are prone to sparks when in contact with plugs, increasing the degree of danger.

Specifically, the advantages of plastic switches include:

?Good insulation performance?: The shell of the plastic switch has good insulation, which can effectively prevent current leakage and electric shock accidents.

?Low risk of electric shock?: Due to the insulation performance of plastic, the use of plastic switches can reduce the risk of electric shock, especially during long-term use, and will not cause electrical safety problems due to wear and tear.

?Strong protection ability?: Plastic switches have excellent protection against external debris and moisture, reducing circuit short circuits caused by external factors such as dust and water vapor, thereby protecting the safety of household appliances and users.

In contrast, although metal switches have excellent durability and thermal conductivity, they are more expensive and the surface is prone to rust, which may lead to poor contact and damage, increasing the risk of electric shock. Therefore, from a safety perspective, plastic switches are more reliable.

What is the best material for a switch?

The best material for a shrapnel switch is stainless steel. This is because stainless steel has excellent corrosion resistance and mechanical strength, which can meet the long-term use requirements of the switch.

The advantages of stainless steel shrapnel switches include:

?Corrosion resistance?: Stainless steel has good corrosion resistance and can remain stable in various environments, extending its service life.

?Mechanical strength?: Stainless steel has high mechanical strength and can withstand greater pressure and wear, ensuring the stability and reliability of the switch.

?Conductivity?: Although stainless steel is not as conductive as copper, in shrapnel switches, it mainly relies on its mechanical properties and structural design to achieve the switch function, so conductivity is not the only consideration.

In addition to stainless steel, there are other materials used in the production of shrapnel switches, such as:

?Copper?: Copper has good conductivity and elasticity, and is often used in the shrapnel of connector switches, but its cost is relatively high.

?Tin-phosphor bronze?: This material is hard, elastic, and has excellent conductivity. It is often used in switches that require high waterproof performance?.

In summary, stainless steel is the best material for spring switches because it combines the advantages of corrosion resistance, mechanical strength, and cost-effectiveness to meet the long-term use requirements of switches.

What are the four types of switches?

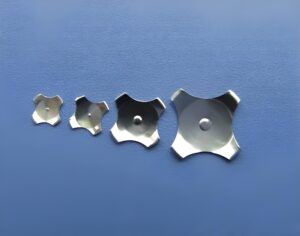

There are four main types of spring switches: metal spring type, hot-pressed convex type, flat touch type, and capacitive sensing type. ?

?Metal spring type?: Metal spring is used as the conducting medium. The advantages include good key feel, uniform force, high stroke accuracy, and a crisp sound during operation, which can clearly know the operation status. The disadvantage is that when the lining is uneven or pasted on a large bending arc, the spring may cause short circuits, malfunctions, and non-rebound phenomena.

?Hot-pressed convex type?: After the contact surface is printed with a film material, the convex point is rolled to form a rebound force. The advantages are high life, which can reach more than 500,000 times, good feel, and the stroke and force can be customized according to customer needs. The disadvantage is that the mold cost is high, and the convex mold needs to be opened. Using it in a high temperature environment may cause the key force to weaken.

?Flat touch type?: The contact point uses a thin film substrate to print the conductor, and no secondary process is used. The advantage is that the key life is long, which can reach one million times, and the conductive contact area is large to ensure the conductivity. The disadvantage is that there is no operating feel, which is easy to cause repeated operation or misoperation.

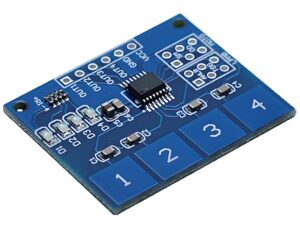

?Capacitive sensing type?: Use a conductor to sense the conduction. The advantage is that it can sense the action within a certain distance like a capacitive touch screen, and the sensing distance can be designed according to the customer’s specifications. The disadvantage is that the finished product qualification rate is low, it is sensitive to the surrounding electromagnetic interference, the design requirements are high, and related electronic components and chips are required. ?

Where are metal switches mainly used?

Metal dome switches are mainly used in membrane switches, contact switches, PCB boards, FPC boards, medical devices and other products. These application fields require switches to have high reliability, sensitivity and corrosion resistance, and metal dome switches can meet these requirements?.

Specifically, metal dome switches are widely used in the following fields:

?Home appliances?: such as air conditioners, washing machines, televisions, etc.

?Automotive electronics?: including electronic handbrakes, steering wheel switches, air conditioning controllers, window controllers, etc.

?Industrial automation?: such as PLC, robots, sensors, etc.

In addition, metal dome switches also have the following advantages:

?Strong conductivity?: The metal dome can effectively transmit current in the circuit to ensure the stability of the circuit.

?Stable rebound?: When the external force is removed, the metal dome can quickly return to its original state to ensure the reliability of the switch.

?Good feel?: The design and material of the metal dome make the switch operation smooth and the user experience good?.

In short, metal switches are very important in the electronic world, and metal dome switches, as the best among them, have been widely used in consumer electronics, automotive electronics, industrial control, medical equipment and other fields with their precise trigger mechanism, excellent feel feedback, high reliability and durability, and miniaturized design.