Tactile buttons are different from common touch-sensitive buttons. Tactile buttons are physical entities that can be pressed. When your finger presses the tactile button, you can clearly feel the slight sinking and rebound of the button. Tactile buttons are usually composed of a carefully designed mechanical structure. During the pressing process, the internal trigger mechanism responds accurately and connects the circuit in series.

What is a tactile button?

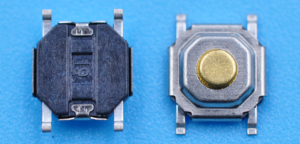

A tactile button is a switch that uses the compression and release of a spring contact piece to open and close the circuit. When the button or key on the tactile switch is pressed, the button applies force to the spring contact piece, compressing the spring contact piece so that it contacts the metal terminal, thereby closing the circuit, allowing current to pass, and triggering the corresponding function of other electronic devices. When the finger leaves the button, the spring contact piece returns to its original state and disconnects the circuit.

The working principle of the tactile button is based on the elasticity and sensitivity of the spring contact piece. When the button is pressed, the spring contact piece is compressed and contacts the metal terminal, forming a low-impedance circuit that allows current to pass. When the finger leaves the button, the spring contact piece returns to its original state and disconnects the circuit. The quality and material of the contacts and contact pieces of a tactile button have an important impact on its performance and life.

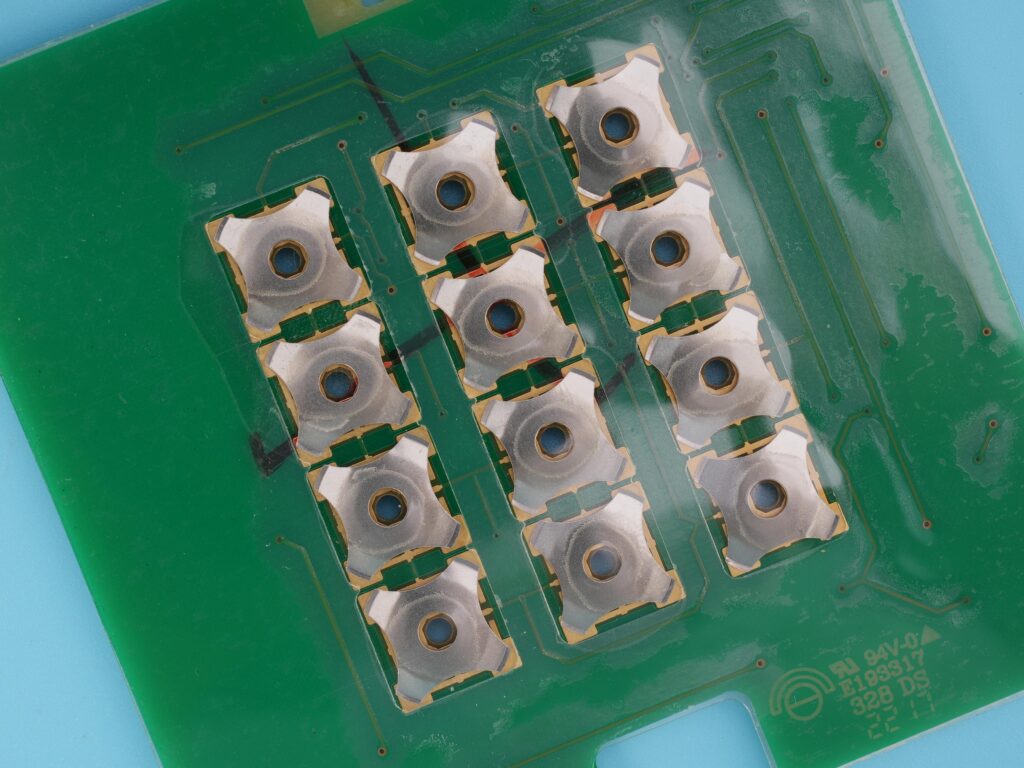

A tactile button consists of a housing, a key, a spring contact piece, and a metal terminal. When the button is pressed, the key applies force to the spring contact piece, compressing it and contacting the metal terminal, closing the circuit. When the finger leaves the button, the spring contact piece returns to its original state, disconnecting the circuit.

How do tactile buttons work?

The working principle of the tactile button is based on the compression and release of the spring contact piece, and the circuit is opened and closed by the contact and separation of the contact. When the button or key on the tactile switch is pressed, the button applies force to the spring contact piece, compressing the spring contact piece, making it contact the metal terminal, thereby closing the circuit and allowing current to flow through the tactile switch. When the finger leaves the button, the spring contact piece returns to its original state, the contact is separated from the metal terminal, and the circuit is disconnected.

A tactile switch is usually composed of a housing, a key, a spring contact piece, and a metal terminal. The quality and material selection of the contacts and contact pieces of a tactile switch have an important impact on its performance and lifespan. High-quality tactile switches can provide better touch and stable performance, and have a longer service life.

What are the different types of tactile buttons?

There are mainly the following types of tactile buttons: tactile buttons, touch switches, and touch-sensitive buttons.

Tactile buttons are a simple switching mechanism, usually made of hard materials such as plastic or metal. They are widely used in home appliances, electronic devices, and industrial controls. Tactile buttons control the circuit through a touch sensor, are easy to operate, and have the advantages of small contact resistance, precise operating force error, and diversified specifications.

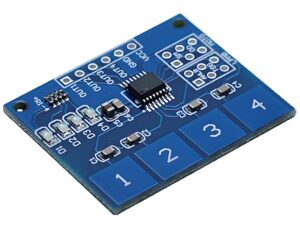

Touch switches include resistive touch buttons and capacitive touch buttons. Resistive touch buttons work by detecting resistance changes caused by human touch, and have high sensitivity and stability; while capacitive touch buttons are based on the principle of inductive capacitance between conductive objects, are not affected by weather and human resistance changes, and have unlimited life and no mechanical parts.

A touch-sensitive key is a key implemented using touch-sensing technology. It detects touch behavior by sensing the capacitance or resistance change of the human body and converts it into an electrical signal to realize the operation function. This type of key has high sensitivity, beautiful appearance and good user experience, and is widely used in controlling home appliances, medical equipment, public facilities and industrial control.

Which is quieter, tactile or linear?

Generally speaking, tactile buttons are quieter than linear buttons.

Linear buttons usually refer to buttons that have no obvious sense of paragraphs and go straight up and down during the pressing process. When such buttons are pressed and popped up, if the internal structure design is not specially silent, they may produce certain sounds due to the collision and friction of mechanical parts. For example, some linear axis keys in traditional mechanical keyboards have certain key sounds when used.

Tactile buttons simulate the feeling of pressing buttons by detecting pressure and generating vibrations. The sound generated during its operation mainly comes from the slight vibration sound of the vibrating parts (if there is a vibration feedback function). This sound is usually very slight and much quieter than the mechanical collision sound of linear buttons.

However, if the linear button is specially designed to be silent, such as adding cushioning materials, optimizing the internal structure, etc., the noise can be reduced to a certain extent, but in general, under the same conditions, the tactile button will still be quieter.

What is the difference between a tactile button and a push button?

The main difference between tactile buttons and push buttons is their working principle, feedback method and applicable scenarios.

Tactile buttons are similar to traditional mechanical buttons, but are smaller and support pressure sensing. It is usually located on the side or bottom of the device, with a groove to distinguish the volume adjustment area. Tactile buttons make a click when pressed and provide instant tactile feedback. Even if the device is turned off or out of power, users can move the button and perform pressure sensing.

Push button switches start the current by pressing the actuator within a certain stroke, and cut off the current by pressing the actuator again. Traditional mechanical push button switches are simple to operate. You only need to press or release the button to turn the circuit on and off, which is very convenient and easy to use.

In terms of function and usage experience, tactile buttons support remote control and pressure sensing, providing higher intelligence and convenience. Traditional push button switches are more stable and durable, suitable for a variety of environments and scenarios.

Which is better clicky or tactile?

Clicky buttons and tactile buttons have their own advantages and disadvantages, and the choice depends on the specific application scenario and user needs.

Clicky buttons usually refer to operations performed on a touch screen, and users can complete the operation by lightly touching the screen with their fingers. The advantages of this type of button include:

Easy to operate: Users only need to lightly touch the screen to complete the operation, which is very convenient and fast.

Modern appearance: Touch screen devices usually give people a high-tech and modern feel.

Versatility: Through different click times and combinations, multiple functions can be achieved to meet the needs of complex operations.

However, clicky buttons also have some disadvantages:

Complex maintenance: Once a fault occurs, the maintenance cost is high, because the touch screen is controlled by a whole circuit board, and the entire circuit board needs to be replaced during maintenance.

Not suitable for all environments: In some environments where physical buttons are required, clicky buttons may not be reliable enough.

Tactile buttons refer to buttons with physical buttons, and users need to press physical buttons to complete operations. The advantages of this type of button include:

Durability: Physical buttons are usually more durable and can withstand more usage.

Wide range of applications: In some special environments, such as kitchens and other places that are easy to get dirty, physical buttons are easier to clean and maintain.

Obvious feedback : Users can clearly feel the feedback of the button press through the feel, and the operation experience is better.

However, tactile buttons also have some disadvantages:

Traditional appearance: Compared with the modern feel of touch screens, physical buttons may appear more traditional and backward.

Space occupied: Physical buttons require more physical space and are not suitable for devices with limited space.

In summary, the choice of click buttons or tactile buttons needs to be determined according to specific application scenarios and user needs. If you need a modern, multi-functional scenario and don’t mind the complexity of maintenance, you can choose a click button; if you need a durable, wide range of applications and don’t mind the traditional appearance, you can choose a tactile button.

Conclusion:

In short, tactile buttons are unique in the wave of technological development with their depressible physical characteristics. It not only retains the operating texture of traditional buttons, but also incorporates the precision and efficiency of modern technology. In the future, I believe that tactile buttons will continue to play their unique advantages and bring more convenience and surprises to our lives and work.