Metal domes are important components in a variety of electronic devices, providing tactile feedback and reliability in button interfaces. Assembling a metal dome onto a printed circuit board (PCB) is a critical step that requires careful consideration of methods, advantages, precautions, and potential pitfalls. Best Technology has rich experience in both the PCB industry and the metal dome industry. Below, I will introduce to you in detail the methods and advantages of metal dome assembly.

Can a metal dome be soldered to a PCB?

Metal domes can be assembled onto PCBs using various methods, including:

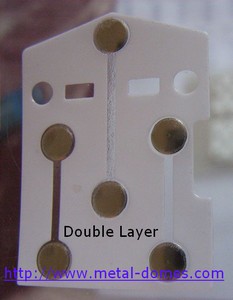

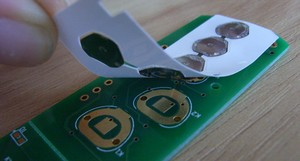

Direct Insertion:It can be directly inserted into the pinholes of the PCB and fixed; or a Metal dome can be made with tape, and the Metal dome and PCB can be glued together for conduction, which is called a dome array.

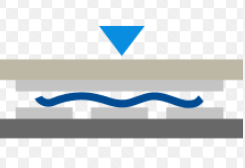

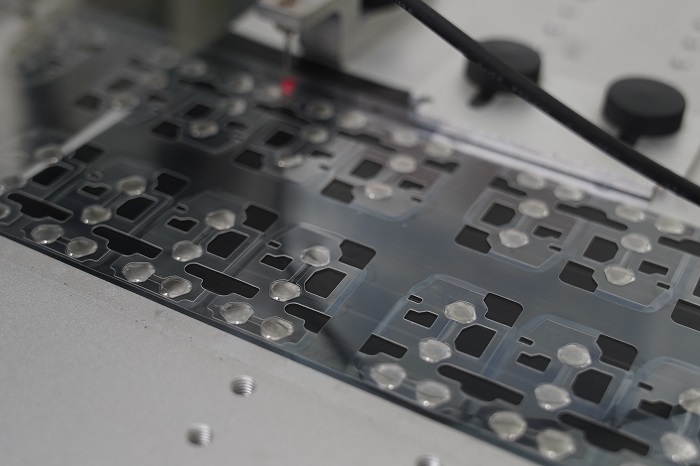

Dome Array: Metal domes can be affixed to PCBs using adhesive tape, creating a dome array. However, welding metal domes directly onto PCBs is not recommended. This is because metal domes possess a slight arc and ductility. When pressed, they tend to extend slightly. Welding directly onto PCBs can limit this flexibility and potentially cause the metal domes to become concave with prolonged use.

Precautions for Metal Dome Assembly

When working with metal domes, it is essential to observe specific precautions to maintain their integrity and functionality:

Avoid Sharp Objects: Do not use sharp objects to press the metal domes to prevent damage.

Avoid Overloading (Heavy Objects): Ensure that products are not subjected to heavy objects that may cause deformation or damage to the metal domes.

Physical Inspection: Pay close attention to any physical external damage on the metal domes, as this can impact performance.

Minimize Direct Contact: Refrain from touching the metal domes directly with bare hands to prevent contamination.

Avoid Exposure to Solvents: Ensure that products do not come into contact with special solvents, as these can affect the performance of metal domes.

Maintain Clean PCB Pads: PCB contact pads in contact with metal domes should not contain foreign matter, as this can affect the conductivity of the domes.

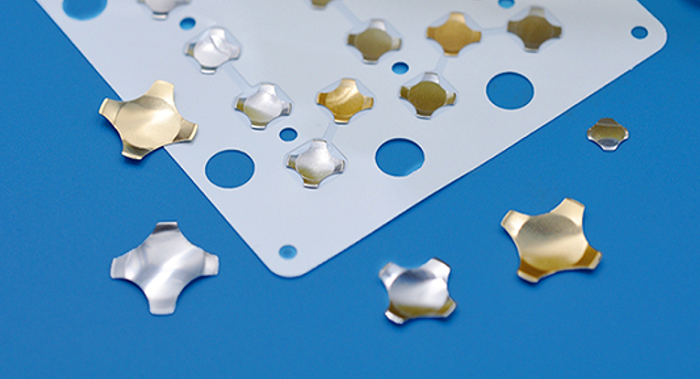

Advantages of Making Metal Dome Arrays

Creating metal dome arrays offers several advantages:

Enhanced Efficiency : Metal domes can be processed into a single adhesive film, streamlining the assembly process and significantly improving efficiency. This eliminates the need to assemble metal domes individually.

Protection Against Contamination : Covering metal domes with PET adhesive paper safeguards them against dust and contamination, ensuring optimal performance over time.

firmly attached : Dome arrays provide a more secure attachment of metal domes to the circuit board, enhancing overall durability.

Best Technology considers methods, materials and precautions to ensure that metal domes function optimally during use. In addition to the assembly methods and some precautions introduced above, Best also undergoes strict inspections when producing metal domes to ensure the product quality of the metal domes. If you want to learn more about Best Technology’s dome array, you can contact us.