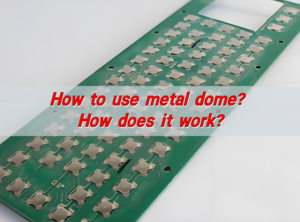

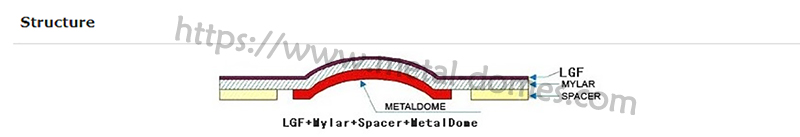

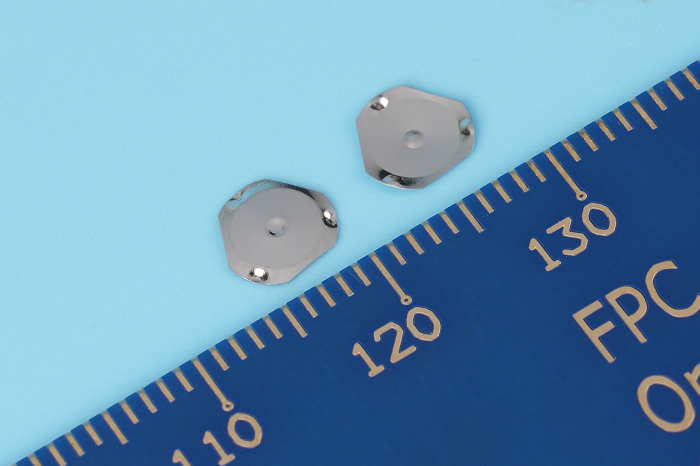

Metal domes are a critical component used in various electronic devices, providing tactile feedback and functionality. As a leading provider of packaging solutions, we understand the importance of delivering metal domes in a safe and secure manner. In this article, we will explore the best packaging methods for metal domes, ensuring their protection during transportation and storage.

Why It Is Important for Proper Package?

Before diving into the specific packaging methods, it is essential to highlight the significance of proper packaging for metal domes. These small, delicate components are susceptible to damage from external factors such as moisture, dust, and physical impact. By implementing appropriate packaging techniques, we can ensure that metal domes reach their destination in pristine condition, ready for use in electronic devices.

Different Packing Methods for Metal Domes

Usually, Best Technology has 4 types of packaging methods for snap domes:

1.Anti-Static Packaging for ESD Protection

Electrostatic discharge (ESD) poses a significant threat to electronic components, including metal domes. To safeguard against ESD, anti-static packaging is crucial. This type of packaging is designed to dissipate static electricity and prevent its accumulation on the surface of the metal domes. Anti-static packaging methods include:

a)Anti-static bags

These specialized bags are made from materials that have low or no static charge, effectively shielding the metal domes from ESD. The bags also offer protection against dust and moisture.

b)Conductive foam

Another effective option is to use conductive foam inserts inside the packaging. The foam absorbs and dissipates any static charges, further minimizing the risk of ESD damage.

c)Humidity control

Controlling humidity levels within the packaging is vital to prevent ESD. Moisture-absorbing materials, such as desiccant packs, can be included to maintain optimal humidity conditions.

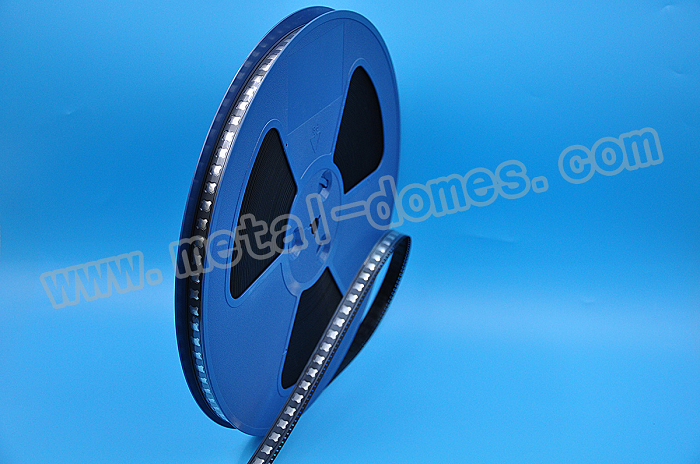

2.Tape & reel package

The tape and reel packaging method, which shares similarities with the packaging used for electronic components, provides a convenient solution specifically tailored for SMT (Surface Mount Technology) peel-and-place machines. This packaging technique involves placing metal domes in a continuous strip of tape, with the domes evenly spaced and secured in individual compartments or pockets. The tape is wound onto a reel, creating a compact and organized packaging format. The advantages of tape and reel packaging are numerous.

a)Efficient and save time

It streamlines the process of loading metal domes onto SMT machines,allowing for efficient and automated assembly. The continuous strip of tape ensures a steady supply of domes, eliminating the need for manual handling or individual picking. This results in enhanced productivity and reduced assembly time, making it an ideal packaging method for high-volume manufacturing.

(Metal domes in tape and reel package)Â

b) Convenient for transportation and storage

The tape and reel packaging format provides excellent protection for metal domes during transportation and storage. The tape acts as a barrier, shielding the domes from external elements such as dust, moisture, and physical damage. It also helps to maintain the integrity and positioning of the domes, preventing any shifts or misalignment that could occur during handling or shipping.

c) Easy to inspection

The clear visibility of the metal domes on the tape allows for easy inspection, quality control, and verification of the quantity and type of domes in each reel. This promotes traceability and simplifies inventory management, ensuring accurate tracking of components throughout the supply chain. Additionally, the compact and lightweight nature of tape and reel packaging optimizes storage space and facilitates efficient logistics. Reels can be easily stacked, stored, and transported, maximizing the use of available storage areas and minimizing the risk of damage or loss.

3.Make them into dome array or dome sheet

In certain instances, metal domes can be conveniently packed using customized PET adhesive tape, commonly known as dome arrays or dome sheets. This packaging method provides a practical and efficient solution for organizing and handling metal domes.Dome arrays or dome sheets consist of a precisely designed tape with individual compartments or pockets that securely hold metal domes. The domes are accurately positioned within each compartment, ensuring their proper alignment and preventing any movement or dislodging during transportation or storage.

(Dome array)Â

One of the key advantages of dome arrays or dome sheets is their ease of use. The metal domes are pre-arranged and affixed onto the adhesive tape, eliminating the need for manual sorting or positioning during assembly. This significantly simplifies the integration process and saves valuable time, particularly in automated production lines.

4.Customized Trays and Tubes for Organization and Safety

To enhance organization and ease of handling, customized trays and tubes can be utilized for packaging metal domes. These packaging solutions provide the following advantages:

a)Secure storage

Metal domes can be organized and stored neatly in trays or tubes, reducing the risk of misplacement or damage. The customized design ensures a snug fit, preventing any movement during transportation.

b)Ease of identification

Clear trays or tubes allow easy visibility and identification of different types and sizes of metal domes. This streamlines inventory management and improves overall operational efficiency.

c)Protection against contamination

Customized trays and tubes can be made from anti-static materials, providing an additional layer of protection against ESD and dust contamination.

Labeling and Documentation for Traceability

In addition to proper packaging, labeling and documentation play crucial roles in metal dome packaging. Including clear and accurate information ensures traceability and quality control throughout the supply chain. Key elements of labeling and documentation include:

i. Part numbers: Each metal dome should be clearly labeled with a unique part number, simplifying identification and referencing.Â

ii. Batch numbers: Including batch numbers enables effective tracking of specific production runs, facilitating quality control and issue resolution.

iii. Date of manufacture: The date of manufacture provides valuable information for tracking product age and shelf life.

At Best Technology, we have extensive expertise in metal domes. Our capabilities extend beyond snap dome packaging; we are also highly skilled in metal dome manufacturing. As a leading provider of metal dome & dome array solutions, our dedication is focused on delivering unparalleled protection and top-notch quality for metal domes. Our commitment goes beyond meeting industry standards â we aim to exceed them and guarantee customer satisfaction.Â

We invite you to reach out to us or visit our website to discover more information about our comprehensive range of snap domes and dome arrays. We are eager to share our knowledge and assist you in finding the perfect solution for your needs.