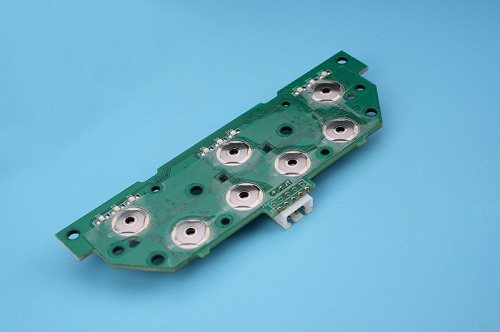

Dome arrays are always assembled with Printed Circuit Boards (PCBs) or flex circuits as tactile switches that provide reliable and responsive feedback to users in electronic devices. However, one common issue with metal dome arrays is that they can lift up or “pop” off the PCB after being placed, causing malfunction or failure of the switch. In this article, we will discuss the reasons behind this issue and some possible solutions.

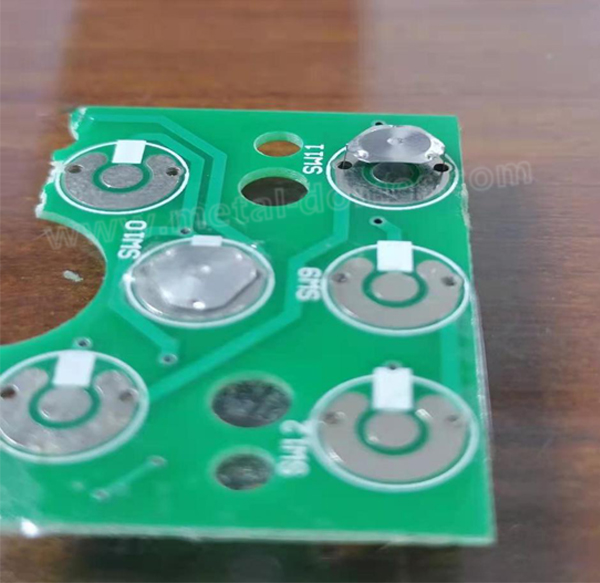

(Metal dome array on PCB)

Understanding the Design of Metal Dome Arrays

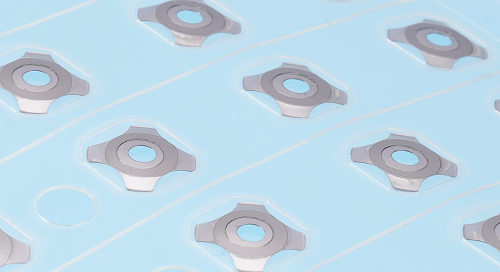

Metal dome arrays consist of a sheet of metal domes, which are small metal discs with a raised center, that are mounted onto a PCB. The domes are usually made of stainless steel or nickel-plated phosphor bronze, and are designed to be compressed when a user applies force on them. This compression causes the dome to collapse and make contact with the conductive pad on the PCB underneath it, creating a connection and activating the switch.

The metal domes are typically held in place by an adhesive tape or film that covers the conductive pads on the PCB. When pressure is applied on the dome, the adhesive tape stretches and allows the dome to compress. However, when the tape is not properly bonded or the dome is too large, it can lift up from the PCB, resulting in a malfunctioning switch.

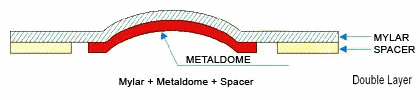

And when the dome array is a double-layer structure, the thickness of upper mylar layer is about 0.05mm, the thickness of spacer layer is about 0.075mm, if the dome you used are high-height series such as triangle metal dome or four-leg metal dome (height always from 0.4~0.7mm), the space between metal dome and spacer is too big. Once the metal dome is close to the outline, it is easy to make this area of dome array tilt up.

(Double layer dome array structure)

Causes of Metal Dome Arrays Lifting up

There are several reasons why metal dome arrays may lift up when placed on a PCB:

1. Insufficient Bonding StrengthOne common reason for metal dome arrays lifting up is insufficient bonding strength between the adhesive tape and the PCB. This can occur if the tape is not properly applied or if the surface of the PCB is not clean. Inadequate pressure or temperature during the bonding process can also contribute to weak bonding.

2. Size and Shape of Metal DomeThe size and shape of the metal dome can also affect its ability to stay in place. If the dome is too large or has a sharp edge, it may be more prone to lift up from the PCB. The shape of the dome can also impact its ability to compress and make contact with the conductive pad.

3. Environmental FactorsEnvironmental factors, such as temperature and humidity, can also impact the bonding strength of the adhesive tape and the metal dome array. Extreme temperatures or humidity can cause the tape to weaken or lose its adhesion, leading to the dome lifting up from the PCB.

How to Prevent Metal Dome Arrays from Lifting up on PCBNow that we have discussed the reasons behind the lifting up of metal dome arrays on PCB, it’s important to know how to prevent this issue. Here we listing some effective solutions to prevent metal dome arrays from lifting up on PCB:

- Use proper adhesive tape

It’s essential to use the appropriate adhesive tape for attaching the metal dome array to the PCB. The adhesive tape should have high adhesive strength and should be compatible with the material of the metal dome array and PCB.

- Choose the right size of adhesive tape

The adhesive tape should be slightly larger than the size of the metal dome array to ensure proper adhesion. However, if the tape is too large, it may cause stress on the corners of the tape, leading to lifting up.

- Apply sufficient pressure

Ensure that sufficient pressure is applied during the assembly process to ensure proper bonding between the metal dome array and the PCB.

- Make spacer thicker

Make the space thicker can effectively solve the lift up problem, due to when the spacer thicker, then the space between spacer and metal dome is not too much.

- Control the assembly environment

The temperature and humidity of the assembly environment should be controlled to prevent the adhesive tape from becoming too dry or too moist, which may affect the adhesion strength. Our SMT work shop always control the room temperature around 25oC +/-3oC, and the humidity is 35%-70%, this is the most suitable temperature for assembly.

- Optimize the design

The design of the metal dome array and PCB can also affect the adhesion strength. By optimizing the design, the stress concentration on the corners can be minimized, thereby reducing the chances of lifting up. Below are some common FAQs about metal dome array assemble to PCB, hope this can help you to better understand and properly design dome array.

1. Q: Can I use any adhesive tape for attaching metal dome arrays to PCB?

A: No, it’s important to use the appropriate adhesive tape with high adhesive strength and compatibility with the material of the metal dome array and PCB.┬á

2. Q: What is the ideal size of adhesive tape for attaching metal dome arrays to PCB?

A: The adhesive tape should be slightly larger than the size of the metal dome array to ensure proper adhesion.

3. Q: What is the impact of temperature and humidity on the adhesion strength of metal dome arrays?

A: The adhesion strength of metal dome arrays can be affected by the temperature and humidity of the assembly environment, with excessive dryness or moisture leading to weaker adhesion.

4. Q: Can the design of the metal dome array and PCB affect the adhesion strength?

A: Yes, by optimizing the design, stress concentration on the corners can be minimized, reducing the chances of lifting up.

5. Q: What are the consequences of metal dome arrays lifting up on PCB?

A: The consequences of metal dome arrays lifting up on PCB include malfunctioning of electronic devices and decreased durability.

This is the end of the sharing, if you have any questions or solutions about the lift up problems, welcome to contact us at any time.