Tactile metal domes are momentary switch contacts made of stainless steel, widely used in electronic devices to provide clear tactile feedback. They are commonly used in membrane switches, touch switches, etc., can withstand frequent operations, have long life and high reliability. Tactile metal domes realize the on and off of the circuit through their elastic deformation, provide a clear touch when pressed, and return to their original state after releasing, ensuring the stability and reliability of the circuit.

As a professional tactile metal dome manufacturer, BEST Technology provides customized services and can design metal domes of different sizes, shapes and strengths according to customer needs. Our products are widely used in consumer electronics, industrial equipment, medical equipment and other fields to ensure high quality and consistency. We have advanced production equipment and a strict quality management system, which can quickly respond to customers’ customized needs and provide a full range of services from design to production. Choosing us means choosing a professional, efficient and reliable partner.

How do tactile metal domes make conntact with pcb?

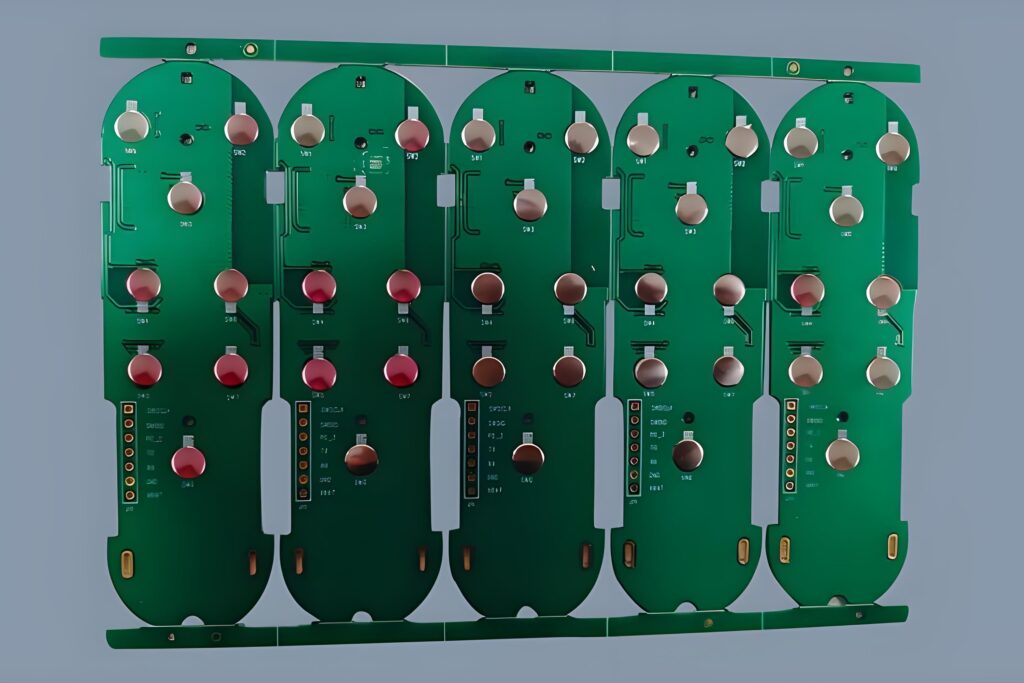

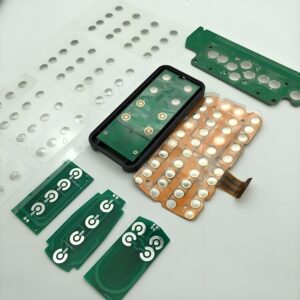

The way a metal dome switch functions is both simple and brilliant. A dome switch PCB design includes a printed circuit board layered with conductive traces. Above this PCB lies a spacer, and on top of that, the metal dome itself.

When the dome is pressed, its center collapses downward, completing the circuit by touching the trace on the PCB. That pressure creates a snap-like feedback that confirms to the user that the button has been pressed. Once released, the dome pops back to its original shape, ready to be used again.

This tactile, audible response is what makes the tactile metal dome switch feel so satisfying. It’s reliable, quick, and clean—ideal for high-performance devices. No guesswork. Just precision.

What makes metal dome switches better than rubber domes?

Unlike rubber dome switches, which rely on pressure to deform silicone, metal domes offer much sharper tactile feedback. That means a better feel and faster reaction. In fields like aerospace, medical tech, and industrial controls, that difference matters.

Rubber can wear down, especially under frequent use. Metal domes, made from stainless steel, last much longer. They’re durable, stable, and perform consistently over time. While rubber can feel mushy or uncertain, snap dome switches respond with a click that’s easy to feel and hear.

Also, rubber domes tend to degrade in extreme temperatures and humidity. Metal domes don’t. Their resistance to weather and corrosion gives them the edge.

So when you need high-speed activation, longevity, and crisp feedback, the choice is clear—tactile metal domes win.

Why use a custom tactile metal dome?

Every product is different. And off-the-shelf parts don’t always cut it. Custom domes can be designed to match that exact force profile. This level of control ensures the perfect user experience.

You can also choose the dome shape—round, triangle, or four-leg. Each has its own characteristics. Custom options also allow adjustments in size, click ratio, travel distance, and even plating.

So don’t settle. The right custom tactile metal dome improves the user experience, and keeps your device one step ahead.

How does a metal dome give tactile feedback?

Tactile feedback isn’t just about feel—it’s about communication. It tells the user: “Your action worked.” That confirmation builds trust.

The magic of a metal dome tactile switch lies in its construction. Each dome is engineered to respond to pressure by “snapping.” This mechanical action creates a physical and often audible click. The resistance before the snap, followed by a release, forms what users recognize as tactile feedback.

The feeling is sharp, responsive, and unmistakable. That’s the difference between a button that feels alive and one that feels lifeless.

The design of the dome—height, thickness, and material—affects the tactile force and sound. By controlling these, manufacturers create a unique switch feel.

Metal dome tactile feedback is essential in mission-critical applications. It confirms the command. It reduces input errors. And it creates a sense of quality in every press.

How does a triangle tactile metal dome work?

Among the various dome shapes, the triangle tactile metal dome stands out for its unique mechanical structure. Unlike round domes, triangle domes feature three legs and a central contact area.

This design offers highly centered actuation. When pressed, the force flows evenly through all three legs. That ensures consistent tactile response, even after thousands of presses.

Triangle domes are ideal for small, high-density layouts. They take up less space and provide faster recovery after actuation. This makes them perfect for handheld devices, slim keypads, and compact controls.

The triangle tactile metal dome keypad delivers snappy action with a clean return. It’s preferred in designs where uniformity and quick response matter.

Plus, triangle domes often have a higher click ratio, meaning a more distinct snap. That’s a win for user satisfaction and trust.

What is a snap dome switch used for?

The snap dome switch is the backbone of modern tactile interfaces. It’s used anywhere a sharp, responsive feedback is needed.

In medical devices, it ensures the doctor knows when a command has been entered. In consumer electronics, it enhances user experience. In industrial machines, it minimizes input errors.

Snap dome switches are found in automotive dashboards, security keypads, smart meters, POS systems, and more. Anywhere reliability and feedback matter, these switches deliver.

Their compact form, fast actuation, and extended life make them the preferred solution. And thanks to the metal dome tactile membrane switch structure, they integrate easily with flexible circuits and overlays.

So whether it’s safety, efficiency, or user comfort, snap dome switches step up where it counts.

What makes a dome switch button so responsive?

Responsiveness is design. A dome switch button responds quickly because of the way the metal dome is engineered.

Each dome has a specific actuation force. When pressed, the dome collapses rapidly and returns just as fast. This quick snap creates immediate tactile feedback.

What boosts responsiveness further is the low-profile structure. The shorter travel distance means less delay. Also, the dome’s shape and thickness ensure energy transfers cleanly from the user’s touch to the circuit.

The metal dome tactile switch instrument is often tuned to microseconds of response time. That kind of speed isn’t just impressive—it’s necessary in industries where time is critical.

And when paired with well-designed overlays or films, the responsiveness only improves. There’s no drag, no lag—just instant reaction.

Whether it’s medical technology, smart controls, or wearable electronics, the feel of a button can define the product. And with custom tactile metal dome switch fabricators, you can bring that feel to life.

Custom designs also allow better integration with printed circuits and overlays. That means slimmer profiles, faster feedback, and less wear. And the visual branding can be baked right into the dome layer.

Conclusion:

Tactile metal domes deliver the feedback your users trust. Compared to rubber domes, they’re sharper, faster, and last longer.

Whether it’s triangle domes for compact designs, snap dome switches for sharp feedback, or metal dome tactile membrane keypads for flexible layouts, these components elevate the experience.

Contact us today at sales@metal-domes.com and Let us create the perfect tactile solution for your idea.