Metal dome is a thin and elastic metal sheet, usually made of stainless steel, beryllium copper, phosphor bronze and other materials, and is widely used in membrane switches, PCB boards, FPC boards and medical devices. It realizes the on and off of the circuit through elastic deformation. When pressed, the center point of the dome is concave, contacting the circuit board to form a loop, and returns to its original state after releasing.

What is a metal dome?

Metal dome is a thin, precisely shaped metal disc that flexes when pressed. It’s usually made of stainless steel, and it’s designed to snap back to its original form after actuation. That “snap” you feel when pressing a button on a membrane switch keyboard? That’s the dome doing its job.

This small component is vital in creating tactile feedback. It tells your fingers that the button press has registered. In short, it adds that satisfying click. But more than just feel, it ensures electrical contact between two traces on a dome switch PCB.

Because of its durability and responsiveness, the metal dome has become a favorite in industries that demand precision, reliability, and endurance.

What is metal dome design?

Designing a metal dome switch isn’t just about shape. It’s about feel. The right design balances actuation force, tactile feedback, and durability.

Start with the force required to press the dome. Lighter forces are easier on the user, but might lack the crisp response. Heavier forces offer firm feedback but can tire fingers in high-use situations. The right design finds a middle ground.

You also need to consider size. A bigger dome may feel softer and slower. A smaller dome delivers sharper feedback, but may wear out faster if overused.

Then comes the placement on the dome switch PCB. Precision matters here. The dome must sit squarely on the contact pads. If misaligned, the dome won’t function properly—or worse, it could damage the switch.

For long-term use, domes must resist fatigue. That’s why high-quality stainless steel is essential. It’s corrosion-resistant, springy, and holds its shape through millions of presses.

Good dome design also avoids over-travel. That means users press just enough to trigger a response without applying excess force. It makes the switch feel fast and responsive.

What are the different metal dome shapes?

Metal domes aren’t one-size-fits-all. They come in several shapes, each offering a unique feel and function. The most popular types include:

- Four-leg domes – These are common in dome switch keyboards. They provide excellent balance and tactile response.

- Three-leg domes – Slightly less stable, but good for tight spaces.

- Round domes – These give a softer feel. They are ideal where user comfort is key.

- Oblong domes – Best used when space is narrow but you still want that crisp response.

Different shapes also change the click sound and the tactile snap. This choice affects how users perceive your product. Whether it’s a soft touch for medical equipment or a loud click for industrial controls, there’s a dome shape that fits.

What were metal domes used for?

At first, metal domes appeared in simple handheld devices. But as technology evolved, their applications grew.

They’ve become critical in consumer electronics, remote controls, telecommunication devices, medical tools, and automotive panels. Their biggest appeal? They deliver tactile confirmation without needing bulky mechanical switches.

When a nurse presses a monitor’s control pad, the dome ensures the input is quick and precise. In an automotive dashboard, the dome behind the button helps drivers confirm actions without needing to look.

Today, they’re everywhere. You’ll find them inside tactile dome switches in military gear, gaming equipment, and smart appliances. The secret to their popularity is that they blend simplicity with effectiveness. They’re small, powerful, and built to last.

What is metal dome switches?

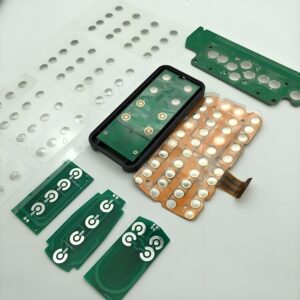

Metal dome switch is the complete setup that includes the dome, a printed circuit board, and a top layer (like a graphic overlay or keypad). Together, these layers create a switch that’s tactile, fast, and reliable.

When you press the top layer, it forces the snap dome to collapse. This connects two circuits on the PCB. Release the pressure, and the dome springs back.

This simple motion creates a reliable electrical signal with every press. And the design allows engineers to stack multiple switches into a sleek, low-profile format. That’s why they’re perfect for slim devices and sealed environments.

With a metal dome switch, you get the best of both worlds: tactile feedback and a compact design. It’s a clear winner for anyone building modern interfaces.

What are the different types of dome switches?

Not all dome switches are created equal. Depending on the use case, there are different builds and materials. Here are the common types:

- Polyester dome switches – Use a formed polyester sheet. They’re low-cost and offer a soft touch but may lack long-term durability.

- Metal dome switches – Use actual stainless steel domes. They provide strong tactile feedback and higher endurance.

- Hybrid dome switches – Combine polyester overlays with metal domes for a middle ground.

- Backlit dome switches – Use LEDs to light up behind the dome. Perfect for dark environments or stylish interfaces.

Choosing the right type depends on your product’s needs. If the feel and reliability are priorities, go with metal dome switches. If price is more critical, polyester domes may work. But for most professional applications, metal domes win by far.

What do membrane switches look like?

Membrane switches look like flat control panels. They’re thin, clean, and usually have graphic overlays that show icons or labels. You’ll see them on microwaves, medical monitors, and industrial controllers.

But underneath the graphics, they’re complex. A membrane switch is built with multiple flexible layers. Each layer serves a purpose—from protection to circuit routing to tactile feedback.

If it includes a metal dome, the tactile experience improves dramatically. The dome is what makes the switch feel responsive. Without it, presses feel mushy and uncertain.

Visually, membrane switches look sleek. They’re often sealed to keep out moisture and dust. That makes them ideal for harsh or high-traffic environments. And they’re highly customizable, with shapes, colors, and button layouts tailored to the device.

What is the difference between membrane and dome switch?

It’s easy to confuse membrane switches and dome switches, but they aren’t the same.

Membrane switch refers to the overall structure—usually made from several plastic layers laminated together. It can have domes inside, but not always.

Dome switch, on the other hand, focuses on the tactile component. It’s the actual mechanism that triggers the signal when pressed.

So, what’s the key difference?

Membrane switches are quiet and flat. They’re often soft and non-tactile unless domes are added.

Dome switches bring the “click” to the experience. They give users that satisfying feedback. They’re usually integrated into membrane switches to enhance feel.

Think of it like this: a dome switch can be part of a membrane switch, but a membrane switch isn’t always a dome switch.

When you want a more intuitive and responsive interface, dome switches are the way to go.

Conclusion:

The next time you press a button and feel that satisfying snap, know that there’s a metal dome working hard behind the scenes. Choosing the right tactile metal dome switch can make a huge difference in the product’s performance and the user’s experience. Whether you’re building a dome switch keyboard or integrating them into a rugged industrial control panel, the design matters.

Need help designing or sourcing your domes? Reach out to us at sales@metal-domes.com