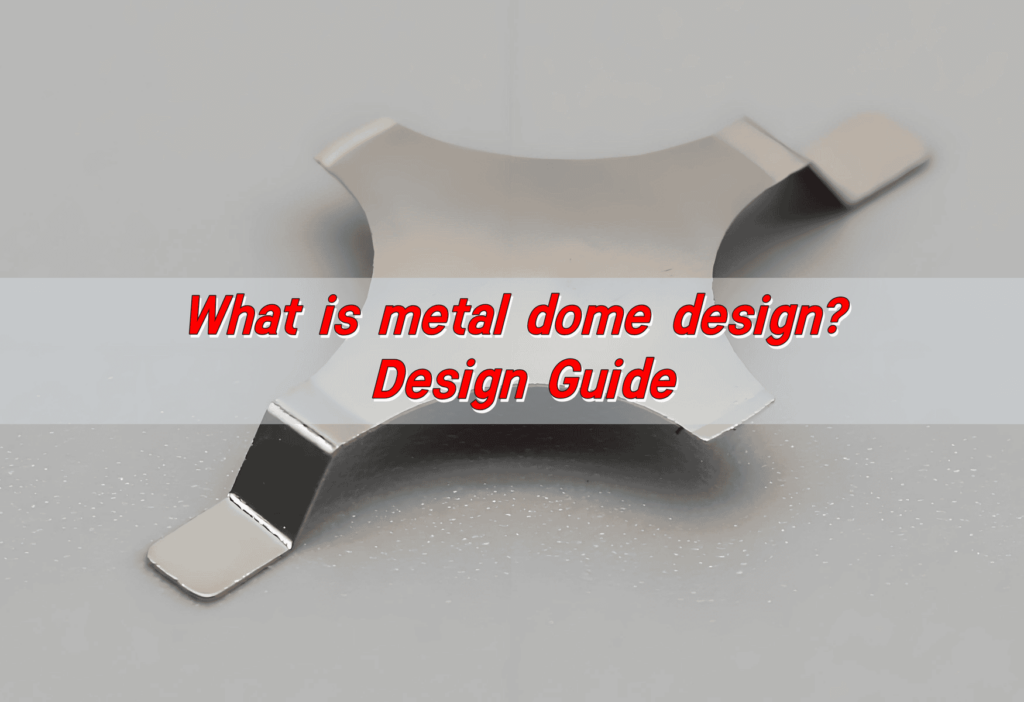

What is metal dome design? Metal dome design is the basis for manufacturing metal shrapnel, which involves the shape, size, material selection and processing technology of the shrapnel. Metal shrapnel is usually designed as an arched structure with a certain radius of curvature. This structure can produce elastic deformation when subjected to pressure, and can return to its original shape when the pressure is released, thereby realizing the on-off function of the circuit.

As a professional metal dome manufacturer, BEST Technology has advanced equipment and technical teams, and can design and produce metal domes of various shapes and sizes according to customer needs. Whether it is a complex structure or high-precision requirements, we have rich industry experience and superb craftsmanship. Choose us to provide reliable metal dome solutions for your products.

What is metal dome design?

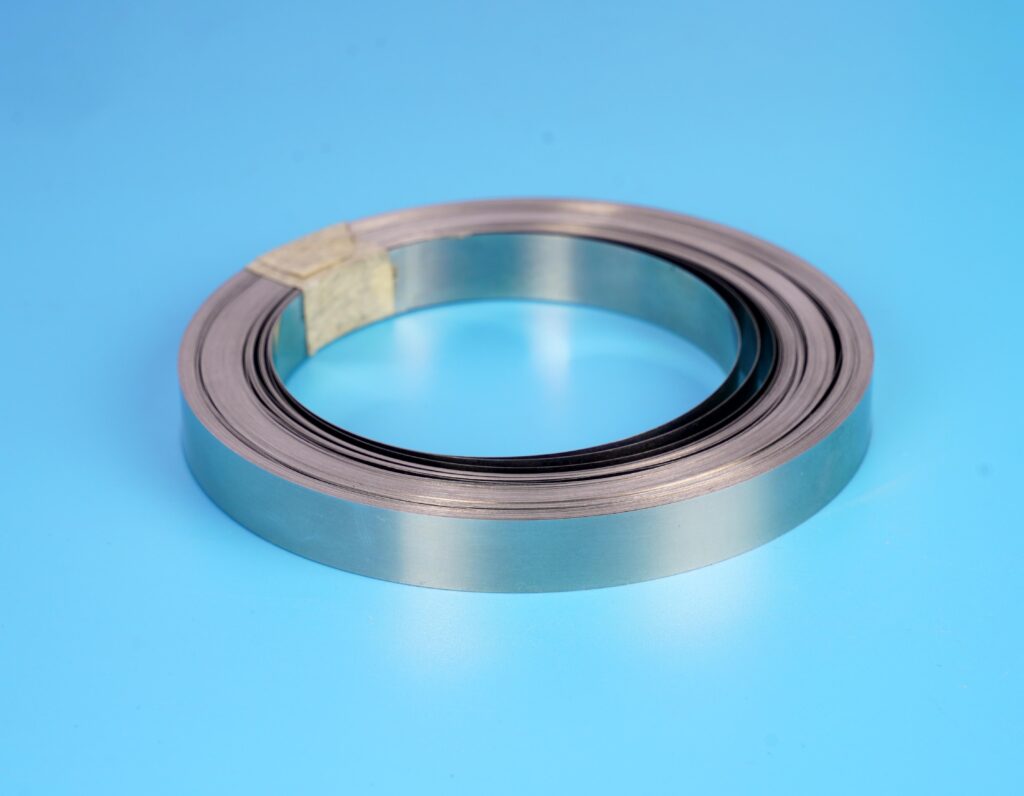

The core of metal dome design lies in the precise selection of materials. Stainless steel (301/304 type) has become the first choice for consumer electronic switches due to its elasticity and corrosion resistance at ultra-thin thickness (0.05-0.1mm); beryllium copper or phosphor bronze can achieve a yield strength of more than 800MPa after heat treatment and strengthening, which is suitable for high-frequency conductive scenarios.

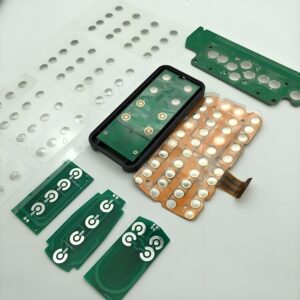

Through circular or cross-shaped geometric design (diameter 3-20mm), the dome can accurately control the pressing contact pressure at 100-600g, ensuring a clear touch and avoiding contact deviation. After optimizing the support points by finite element analysis, the life of modern dome generally exceeds 1 million cycles.

The tolerance of the stamping die needs to be controlled within ±0.02mm, and the defective rate below 0.1% is achieved with optical screening. Surface gold plating can reduce the contact resistance to milliohm level, and the salt spray test verifies its long-term stability in a humid environment.

What is metal dome design called?

Metal dome design is often referred to as tactile dome switch design. It’s a key component in interface technology, offering a snap-action response when pressed. This design is commonly used in dome switch keyboards, industrial control panels, and high-end electronics.

Another term frequently used is snap dome design because of the distinct snapping feel when pressed. This feature improves accuracy and provides users with instant feedback, making it ideal for sensitive applications.

Unlike traditional rubber keypads, metal domes maintain their responsiveness over millions of cycles. Their ability to deliver a consistent, satisfying tactile response makes them superior to other switching technologies.

How to make a steel dome?

The creation of a steel dome requires precision engineering and advanced manufacturing techniques. Every step in the process influences the dome’s durability, electrical performance, and tactile feel.

Step 1: Material Selection

High-quality stainless steel is used for its strength, elasticity, and conductivity. This ensures the dome can withstand millions of actuations without deformation.

Step 2: Precision Stamping

A specialized stamping machine shapes the steel into the desired dome form. This process requires extreme accuracy to maintain uniformity across batches.

Step 3: Heat Treatment

Heat treatment enhances the spring-like properties of the dome, allowing it to return to its original shape after being pressed. This step is critical in defining the tactile response.

Step 4: Surface Coating

A protective coating is applied to enhance corrosion resistance and electrical conductivity. This prevents oxidation and ensures a reliable connection throughout the dome’s lifespan.

Manufacturing a metal dome requires strict quality control. Even the slightest variation in shape or material thickness can impact performance and longevity.

What is the structural design of a dome?

A metal dome’s structural design is based on precise curvature, tension, and contact points. Unlike mechanical switches, metal domes function using their built-in elasticity. Their design ensures smooth activation, reliable contact, and durability.

Core Structural Elements:

Curved Shape: The curvature creates the necessary resistance for a quick snap-back action after being pressed.

Four-Legged or Round Base: These structures provide stability and proper alignment on the PCB.

Central Contact Point: The dome’s center acts as the primary electrical connection, bridging the circuit when pressed.

Different dome structures affect the tactile response. Some provide a light press, while others require higher force, depending on the application.

What is the purpose of a dome structure?

The primary purpose of a metal dome structure is to enhance user interaction and device functionality. These small yet crucial components impact usability, reliability, and performance in various applications.

Key Purposes of Metal Domes:

Tactile Feedback: Metal domes deliver a satisfying snap, improving user experience.

High Durability: They outlast rubber keypads, making them ideal for frequent use.

Accurate Actuation: The design prevents accidental presses, increasing precision.

Compact and Lightweight: Unlike bulky mechanical switches, metal domes allow for sleek, modern designs.

In industries where precision is critical—such as medical devices and aerospace controls—metal domes provide a trusted and reliable switching solution.

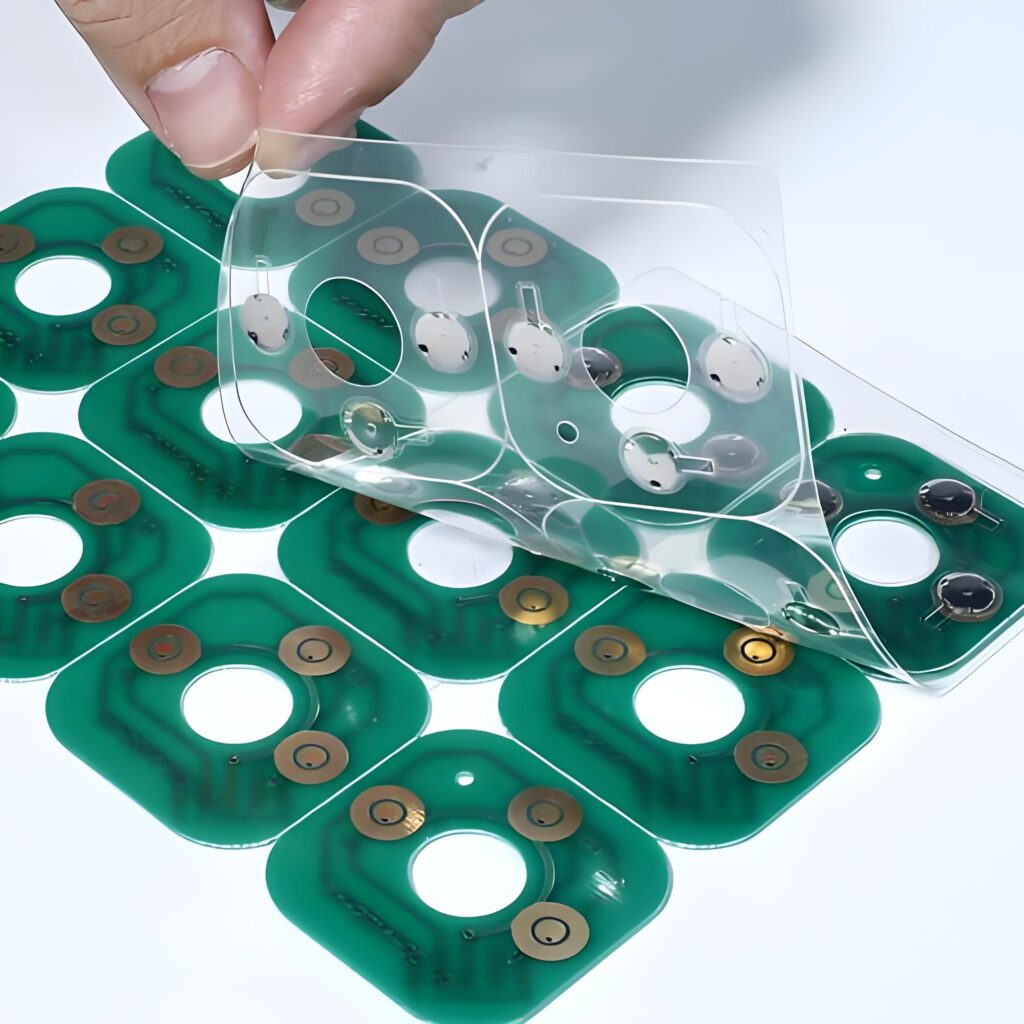

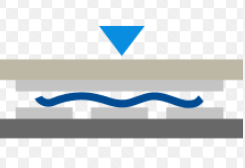

How does metal dome work?

Metal domes complete an electrical circuit when pressed, triggering a response in the connected device. Their function is simple yet highly effective.

Step-by-Step Functionality:

Idle State: The dome rests above the PCB, with its edges touching the circuit board.

Pressing Action: When pressure is applied, the dome collapses, making contact with the circuit.

Current Flow: The electrical path is completed, sending a signal to the device.

Release and Reset: Once pressure is removed, the dome snaps back to its original form, breaking the circuit.

This mechanism enables fast and reliable switch activation. Unlike traditional rubber-based switches, metal domes maintain consistent performance for millions of cycles.

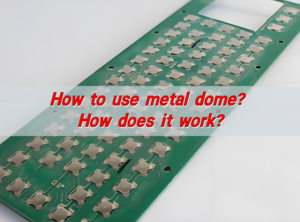

What are the different metal dome shapes?

Metal domes come in various shapes, each designed for specific tactile responses and force requirements. The choice of shape affects actuation force, travel distance, and click sensation.

Common Metal Dome Shapes:

- Round Domes: Offer a soft but defined click, ideal for remote controls and consumer electronics.

- Four-Legged Domes: Provide stability and durability, making them suitable for industrial control panels.

- Triangular Domes: Require higher actuation force, perfect for rugged applications.

- Oblong Domes: Feature a longer shape, often used for customized keypads.

Choosing the right dome ensures the best balance between force, feedback, and longevity.

Advantages of Metal Dome Switches

Compared to rubber or mechanical switches, metal domes offer several key benefits that make them the preferred choice in high-performance applications.

Long Lifespan: Metal domes last millions of cycles, far outlasting rubber-based alternatives. This makes them a cost-effective choice for long-term use.

Enhanced User Experience: The distinct click response provides users with immediate feedback, improving accuracy in input devices.

Compact and Lightweight: Their thin profile allows manufacturers to design sleek and modern devices without sacrificing tactile response.

Consistent Performance: Metal domes maintain precise actuation force, ensuring uniform feedback across all presses.

Versatile Applications: From medical equipment to consumer electronics, metal domes enhance functionality in a wide range of industries.

Conclusion:

Metal dome design is an essential part of modern switching technology. Whether in dome switch keyboards, tactile dome buttons, or dome switch PCBs, these components ensure accuracy, durability, and a superior user experience. For expert guidance on metal domes, contact sales@metal-domes.com