How to fabricate a small circular metal dome? The production of small circular metal dome involves precision craftsmanship, and multiple processes are required from design to finished product. First, the size and shape are designed according to the requirements, and high-quality metal materials such as stainless steel or beryllium copper are selected. They are formed by precision stamping or laser cutting, and then heat treated to optimize elasticity and toughness. Finally, they are pressed and formed by high-precision molds and strictly tested to ensure that each dome has excellent performance and high reliability.

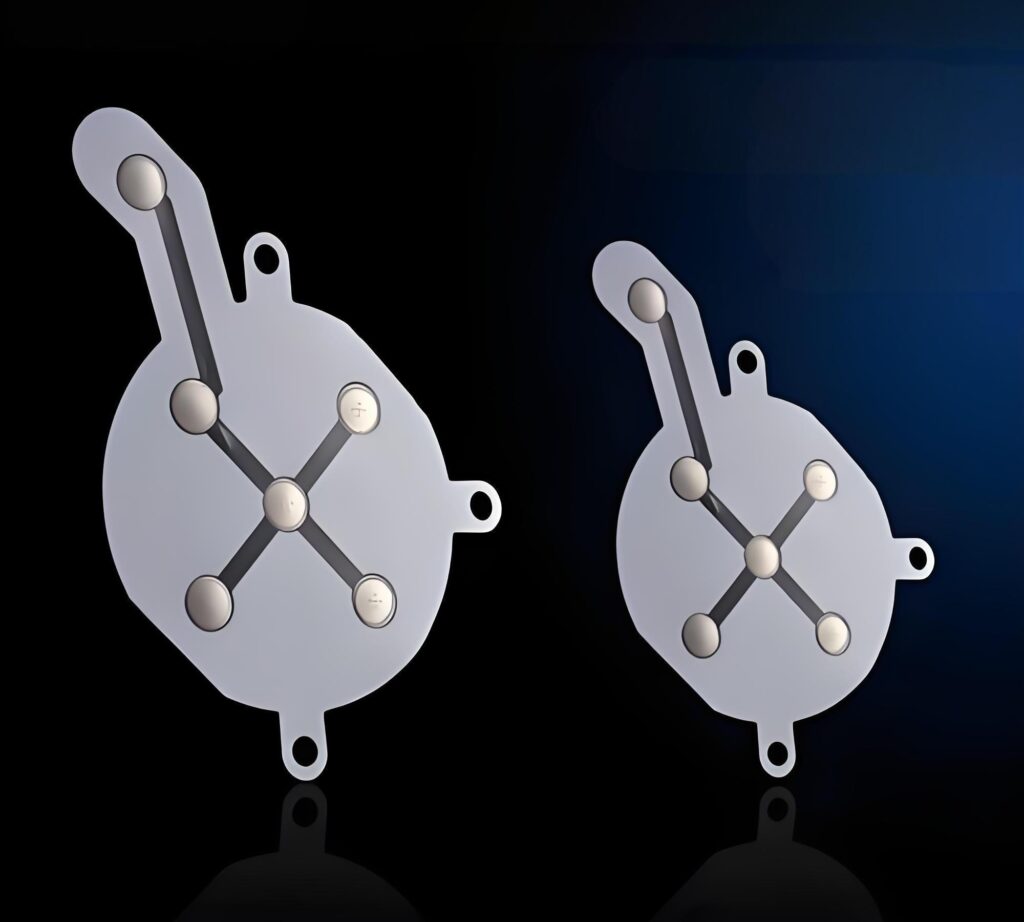

As a professional metal dome manufacturer, BEST Technology has advanced equipment and exquisite craftsmanship, and can manufacture metal dome of various sizes and types. Whether it is a small round dome or a custom dome with a complex shape, we can produce it accurately to ensure that each dome has excellent elasticity and durability to meet your diverse needs.

What is a circular metal dome?

A circular metal dome is a small, round, and flexible metallic component used primarily in switch mechanisms. It acts as a momentary contact switch, delivering tactile feedback when pressed. Made from stainless steel or other conductive metals, these domes ensure durability and reliability in electronic circuits.

When a user presses a button equipped with a round metal dome, it deforms slightly, completing an electrical circuit. Upon release, it returns to its original shape, ensuring longevity and consistent performance. This simple yet effective mechanism makes dome switches essential in consumer electronics, automotive controls, and medical devices.

How to make a steel dome?

Fabricating a steel dome requires precision and expertise. The process starts with selecting the right material. Stainless steel is often used due to its high strength, corrosion resistance, and excellent electrical conductivity.

Material Selection: The first step is choosing the right grade of stainless steel. Thin sheets with high elasticity and conductivity are ideal. The material must withstand repeated use without losing its shape.

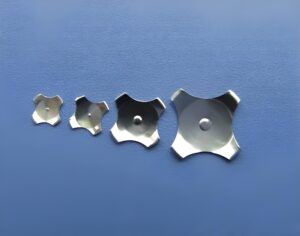

Cutting the Metal Sheet: A precise cutting method, such as laser cutting or stamping, is used to shape the metal dome. High-speed machines cut out perfect circles, ensuring consistency in size and shape.

Forming the Dome Shape: The cut metal piece is then pressed into a dome shape using specialized forming tools. This step is crucial for defining the dome’s height, curvature, and tactile force.

Heat Treatment: To enhance durability, the formed dome metal undergoes heat treatment. This process strengthens the material, ensuring it retains its elasticity even after extensive use.

Surface Finishing: A smooth finish is necessary to prevent oxidation and enhance conductivity. The domes are cleaned and coated if needed to maintain their efficiency over time.

Quality Testing: Every circular metal dome undergoes strict quality control checks. Engineers test them for durability, electrical resistance, and tactile response to ensure they meet industry standards.

How to make a dome shaped?

Shaping a round metal dome requires advanced machinery. Using high-precision forming dies, the metal is pressed into the required dome curvature.

The depth and diameter must be carefully controlled. If the dome is too shallow, it won’t provide a strong tactile feel. If it’s too deep, it may become too rigid. The right balance ensures the dome delivers a satisfying response with every press.

How to make circular metal dome?

A circular metal dome follows the same shaping principles as a dome switch. However, different industries have specific requirements. Some domes require additional coatings for better conductivity. Others need specialized designs to fit complex circuits.

Laser cutting or precision stamping ensures smooth edges and accurate dimensions. Forming machines create the dome curvature, and heat treatment enhances its resilience. The result is a highly durable dome switch that lasts for millions of presses.

What are the sizes of circular metal dome?

Round metal domes come in various sizes, typically ranging from 3mm to 12mm in diameter. The height and force resistance vary depending on the application. Smaller domes are used in compact devices, while larger domes provide a stronger tactile feel.

Different industries require different force levels. A dome switch used in a remote control may require light pressure, while an industrial machine switch may need a firmer response. These variations ensure the domes perform optimally in their respective applications.

What are the advantages of round metal dome?

Superior Tactile Feedback: A round metal dome delivers a crisp and responsive feel, enhancing user experience.

- Durability and Longevity: These domes can withstand millions of cycles without losing performance. High-quality materials ensure they remain functional even after repeated use.

- High Conductivity: Made from stainless steel or plated metals, dome metal ensures excellent electrical conductivity.

- Compact and Versatile: The small size of circular metal domes allows them to fit in compact devices without compromising performance.

- Resistant to Wear and Tear: Unlike rubber or plastic alternatives, metal domes do not degrade over time.

What are the disadvantages of round metal dome?

Although dome switches offer many advantages, they do have some limitations:

Higher Manufacturing Costs: Producing high-precision domes requires specialized equipment and quality materials, which can increase costs.

More Rigid Feel: Compared to membrane switches, metal domes can feel firmer, which may not be suitable for every application.

Potential Noise: The crisp tactile feedback can produce a slight clicking sound, which may not be ideal in noise-sensitive environments.

What are the applications of circular metal dome?

Circular metal domes are found in a variety of industries, providing reliable switching solutions across multiple fields.

Electronics and Consumer Devices: Many household gadgets, such as remote controls, calculators, and gaming controllers, use dome switches for precise input.

Medical Equipment: Medical devices require high-precision dome switches for accurate operation.

Automotive Industry: Car dashboard controls, steering wheel buttons, and other vehicle components use round metal domes for their durability and responsiveness.

Industrial Controls: Machinery and industrial panels often use dome metal switches because they can withstand harsh environments and frequent use.

Aerospace and Military Equipment: In high-stakes applications, metal domes provide the precision and reliability needed for mission-critical operations.

Conclusion:

Fabricating a small circular metal dome requires precision, expertise, and high-quality materials. These tiny but powerful components offer exceptional durability, tactile feedback, and electrical performance.

If you need high-quality circular metal domes, reach out to us at sales@metal-domes.com. Our expert team can help you find the perfect solution for your application.