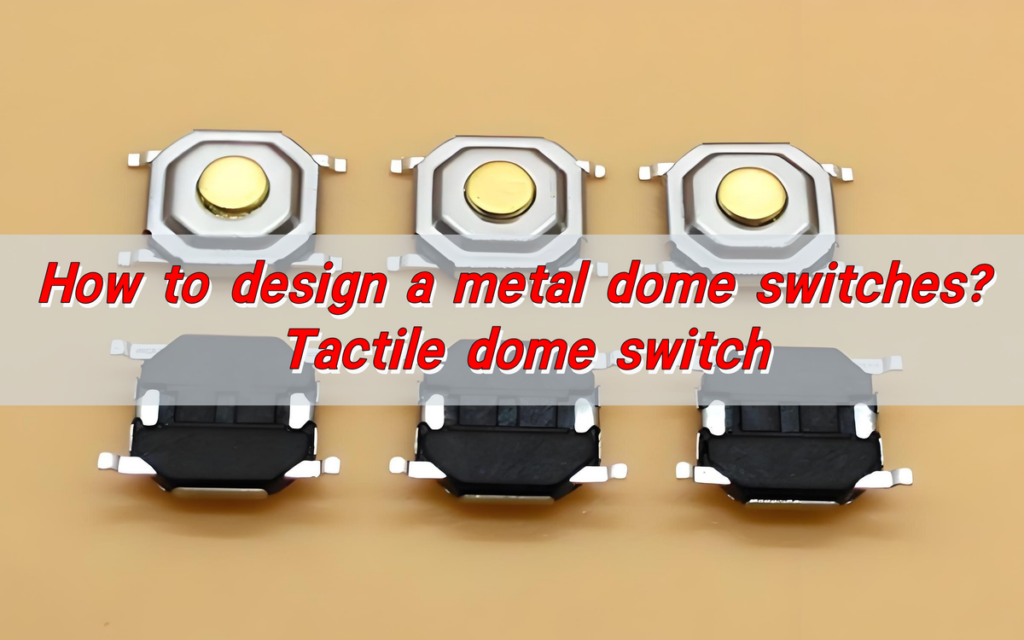

How to design a metal dome switches? Metal dome switches are essential components in modern electronic devices, offering superior tactile feedback and durability. Whether used in industrial machinery, medical devices, or consumer electronics, they ensure precise and reliable actuation. Designing these switches requires attention to factors like force, dome shape, and PCB layout to optimize performance.

As a professional metal dome switch manufacturer, BEST Technology focuses on the manufacture of high-quality metal dome switches. We use high-quality materials to ensure excellent conductivity and durability. In terms of design, we focus on the optimization of dome shape, size and welding process to meet the specific needs of customers. Choosing us means choosing professionalism and reliability.

What is the tactile dome?

A tactile dome is a small, stainless steel component that acts as a switch when pressed. It provides a crisp, responsive “snap,” signaling to the user that an action has been registered. Unlike rubber domes, which provide a softer feel, metal domes offer sharper tactile feedback, improving accuracy and usability.

These domes are used in various applications, from remote controls to medical devices. Their longevity makes them ideal for high-use environments. The distinct click they produce reassures users, preventing accidental key presses and ensuring reliable functionality.

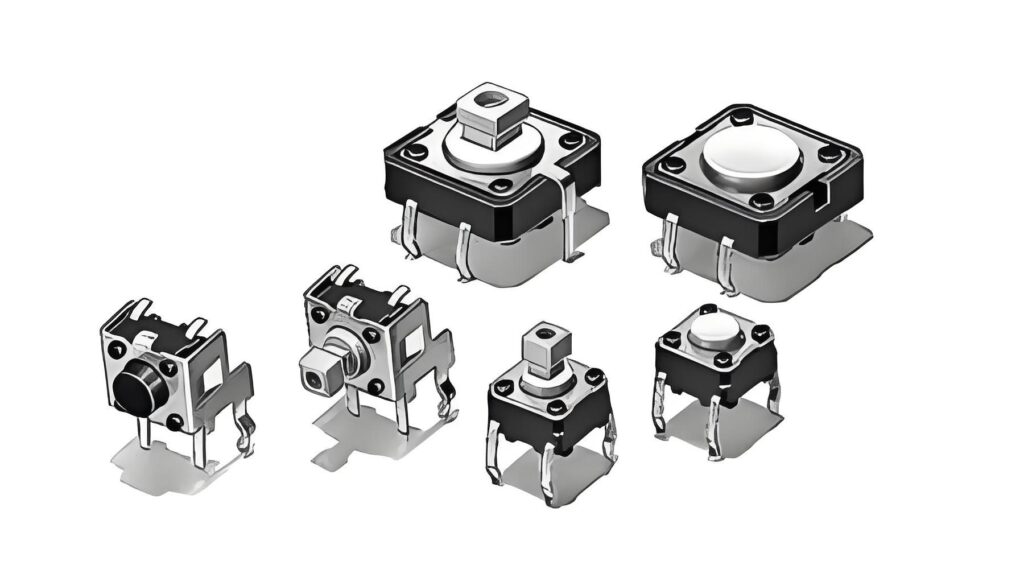

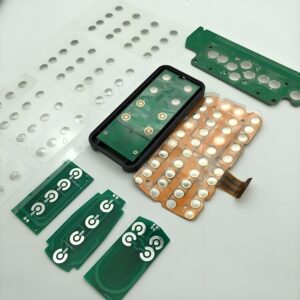

What are the different types of dome switches?

Dome switches come in different shapes and sizes, each offering unique benefits. Choosing the right type depends on the required tactile response, durability, and space constraints.

Four-Legged Domes: These domes have four extended legs that provide a stable actuation. They distribute force evenly, ensuring a consistent tactile response. This type is widely used in membrane keypads and industrial control panels.

Triangular Domes: Triangular domes create a sharper tactile feel, making them ideal for applications requiring strong feedback. They are commonly found in high-precision equipment and rugged keypads.

Round Domes: Round domes offer a softer actuation while maintaining a distinct click. They are often used in consumer electronics, where a balance between comfort and responsiveness is needed.

Oblong Domes: Oblong domes have an elongated shape, allowing them to distribute force across larger buttons. They are beneficial in designs where space is limited but reliability is crucial.

Each type has specific advantages. The right selection enhances user experience and ensures long-lasting performance.

How are domes switch designed?

Designing a dome switch involves several key factors that affect its usability and longevity. Engineers carefully optimize each aspect to create a smooth and responsive interface.

1. Actuation Force

The force required to press the switch varies based on application needs. Lighter forces (around 100g) are ideal for devices requiring quick and effortless actuation. Higher forces (up to 400g) provide stronger feedback, reducing accidental presses.

2. Dome Shape and Size

The shape of the dome determines the actuation feel and durability. A well-designed dome maintains consistent performance over millions of presses. Sizes range from 4mm to over 20mm, depending on application requirements.

3. Click Ratio

The click ratio measures how sharp the tactile feedback is. A higher ratio (above 60%) provides a more defined click, improving user satisfaction. Lower ratios create softer feedback, preferred in quieter environments.

4. Material and Coating

Most domes are made from stainless steel for durability. Some are gold-plated to enhance electrical conductivity and prevent oxidation. Proper material selection ensures reliable performance even in harsh conditions.

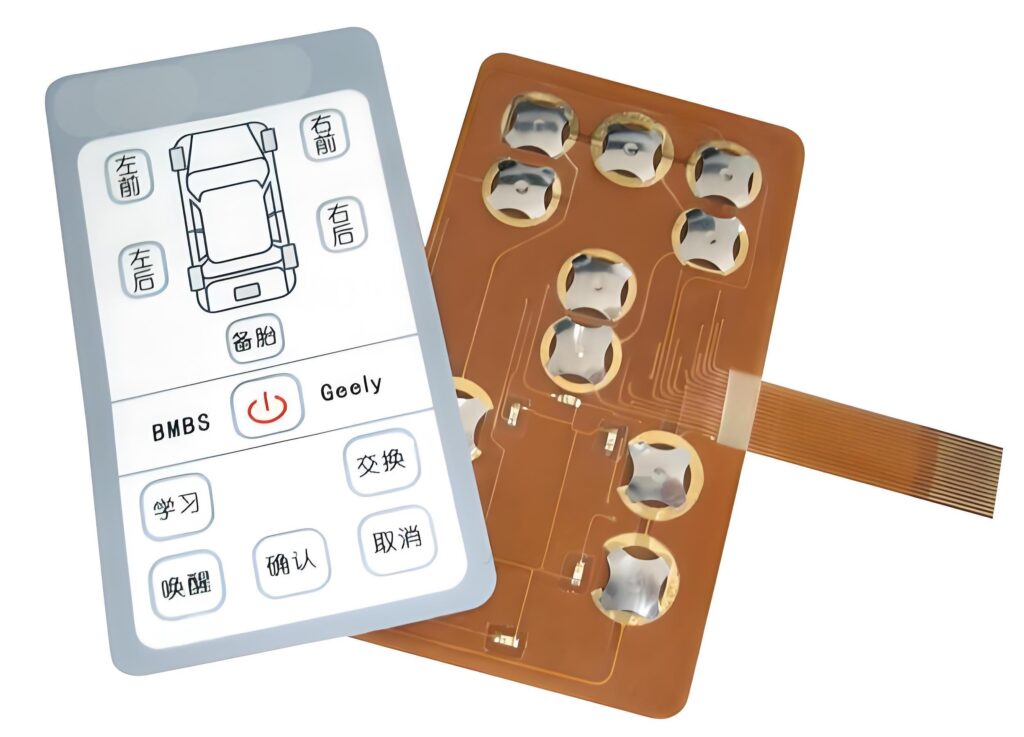

5. PCB Layout and Adhesive Placement

The dome must align perfectly with the PCB’s contact points. Incorrect positioning leads to inconsistent actuation. High-quality adhesives secure the domes, preventing movement while maintaining electrical connectivity.

A well-executed design enhances switch responsiveness, longevity, and overall device performance.

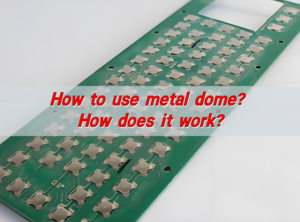

How do dome switches work?

Dome switches operate by momentarily closing an electrical circuit when pressed. Beneath the dome, conductive traces on the PCB remain separated until pressure is applied. When the dome collapses, it bridges the circuit, sending an electrical signal to the device.

The moment pressure is released, the dome snaps back to its original position. This quick recovery ensures the switch is ready for the next actuation. The sharp snap users feel results from the dome’s elasticity, providing both tactile and auditory feedback.

Because of their precise engineering, metal domes offer rapid response times, making them ideal for devices that require accurate input.

Are dome switches good?

Yes, dome switches provide several advantages that make them superior to other switch types. Their key benefits include:

Exceptional Durability: Metal domes withstand millions of actuations without performance degradation. Unlike rubber-based switches, they retain their original force and tactile response over time.

Fast and Reliable Actuation: The sharp tactile feedback ensures users know when a key has been pressed. This makes dome switches ideal for industrial controls, medical instruments, and automotive interfaces.

Lightweight and Compact: These switches add minimal weight to devices, making them perfect for portable electronics. Their compact size also allows for more flexible design configurations.

Superior Electrical Contact: Metal domes ensure consistent and stable signal transmission. The direct metal-to-metal contact minimizes resistance, improving response time and reliability.

Versatile Applications: From consumer gadgets to military-grade equipment, dome switches adapt to various environments. Their resilience makes them the preferred choice for demanding applications.

Compared to membrane or rubber-based alternatives, metal dome switches maintain their performance longer, making them a worthwhile investment.

What is a dome switch keyboard?

A dome switch keyboard uses domes under each key to provide tactile feedback. These keyboards can use either metal or rubber domes.

Metal Dome Keyboards – Provide a sharper tactile response, ideal for professionals who need precision. They last longer and maintain their feel over time.

Rubber Dome Keyboards – Offer a softer, quieter feel. These are common in budget-friendly consumer keyboards but wear out faster.

Metal dome keyboards excel in durability and responsiveness, making them the preferred option for specialized applications.

What is the height of a dome switch?

Dome switch height varies based on design requirements. Standard heights range from 0.3mm to 1.5mm.

Lower domes (0.3mm – 0.6mm) require less force and are used in thin devices.

Higher domes (1.0mm – 1.5mm) provide stronger feedback and are favored in industrial settings.

Choosing the right height ensures the best balance between tactile feedback and user comfort.

Conclusion:

Designing a metal dome switch requires precision. From actuation force to dome shape, every detail impacts performance. Proper design guarantees a crisp, reliable tactile response, ensuring user satisfaction.

Dome switches stand out for their durability, responsiveness, and reliability. Selecting the right dome type and design ensures optimal results. For expert advice on designing metal dome switches, contact us at sales@metal-domes.com