What is an SMD Switch?

An SMD (Surface-Mounted Device) switch is a type of switch designed to be mounted directly onto the surface of a printed circuit board (PCB). Unlike traditional through-hole switches, which require holes to be drilled into the PCB, SMD switches are compact and fit neatly on the board’s surface. They are typically smaller, making them suitable for modern electronic devices where space is a premium.

SMD switches come in a variety of types, such as tactile switches, slide switches, and push-button switches, each serving different purposes in circuit designs. These switches are mounted using soldering techniques, often with automated machines, providing a reliable connection and ensuring minimal risk of board damage.

What is the Purpose of an SMD Switch?

The primary purpose of an SMD switch is to allow users to control electronic circuits. Depending on the design, SMD switches can turn devices on or off, select between different modes, or adjust settings within the system. For example, a tactile SMD switch might be used in a portable device to toggle between modes, while an on/off switch controls the power supply.

SMD switches are highly versatile, making them suitable for a wide range of applications, from mobile phones and wearables to consumer electronics and industrial machinery. Their compact design allows manufacturers to integrate these switches in places where larger components would not fit, while still ensuring that the user experience remains intuitive.

Types of SMD Switches

SMD switches come in various shapes and sizes to cater to different needs. Here are some of the most common types:

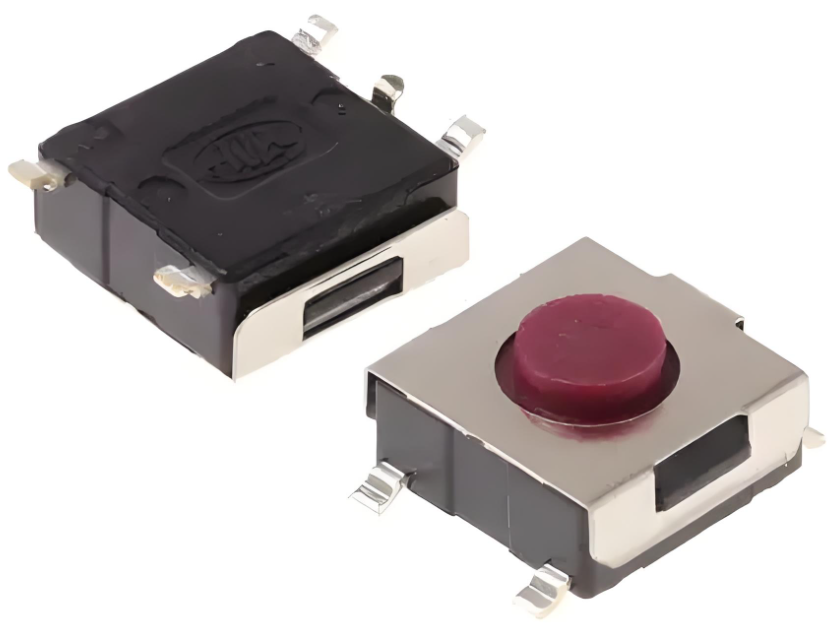

1. Tactile SMD Switches

These are the most common type of SMD switches. They provide a tactile feedback when pressed, often used in applications like keypads, remote controls, or any device requiring a user interface.

2. Slide SMD Switches

Slide switches have a sliding mechanism that allows the user to control a circuit in one or more positions. These are typically used in power circuits for devices like flashlights or even industrial machines.

3. Push-button SMD Switches

These switches work by pushing a button to open or close the circuit. They are commonly used in devices like phones, radios, and even toys.

4. Rotary SMD Switches

Similar to a knob, rotary switches allow users to adjust settings by rotating them. They are used in audio devices, light dimmers, and other gadgets where fine control is needed.

5. SPST and SPDT SMD Switches

Single Pole Single Throw (SPST) and Single Pole Double Throw (SPDT) switches are also popular SMD variants. SPST switches control a single circuit, while SPDT switches can toggle between two different states.

Each of these types is designed for specific uses, making them essential components in various electronic applications. Their compact size ensures they can be used even in small devices without sacrificing functionality.

Advantages & Disadvantages of SMD Switches

Advantages:

- Space Efficiency

One of the most significant benefits of SMD switches is their compact size. They are perfect for devices where space is limited, allowing designers to fit more components into the same area.

- Better Durability

SMD switches are generally more durable than through-hole switches. Their design ensures they are less susceptible to mechanical damage, especially when mounted on a surface.

- Automation in Manufacturing

The ability to automate the placement and soldering of SMD switches makes them ideal for mass production. This reduces the cost of manufacturing and ensures consistent quality across batches.

- Improved Aesthetics

The small size of SMD switches often leads to sleeker, more polished product designs. For consumer electronics, this means thinner, more attractive devices.

- Enhanced Performance

SMD switches typically offer better performance due to their direct connection to the PCB. This reduces the risk of signal degradation, ensuring that the switch functions smoothly.

Disadvantages:

- Difficult to Replace

SMD switches are challenging to replace or repair once they are soldered onto the PCB. If a switch fails, it may require desoldering, which can be tricky without the right tools.

- Manual Handling

Although automated systems place most SMD switches, some models might still require manual handling for specific applications, which could lead to additional costs or mistakes during production.

- Potential for Heat Damage

Since SMD switches are mounted directly on the surface of the PCB, excessive heat during soldering or operation can damage them. However, this is mitigated with proper temperature controls and cooling techniques during manufacturing.

- Limited Space for Larger Switches

While SMD switches are compact, they may not always offer enough space for larger or more robust components, especially for high-power applications.

What is the Difference Between SMD Switch and Through-Hole Switch?

The primary difference between SMD switches and through-hole switches lies in how they are mounted to the PCB. SMD switches are placed on the surface of the PCB and soldered into place, while through-hole switches have leads that go through holes drilled in the PCB and are then soldered on the opposite side.

1. Size

SMD switches are generally much smaller than through-hole switches. This makes SMD switches ideal for compact, portable devices like smartphones, wearables, and remote controls.

2. Assembly

Through-hole switches tend to require more manual labor to assemble and solder, while SMD switches can be placed quickly using automated machines, improving manufacturing efficiency.

3. Durability

SMD switches are often more robust, as they are less prone to damage from mechanical stress compared to through-hole versions, which can be more easily affected by physical impacts.

4. Cost

SMD switches are usually more cost-effective when produced in large quantities due to the automation involved. However, through-hole switches may be preferable in some situations where durability or reliability in harsh conditions is prioritized.

When to Use an SMD Switch?

SMD switches are a great choice when space is limited, or when the device is part of a larger, compact electronic assembly. They are commonly used in mobile phones, medical devices, audio equipment, and various consumer electronics. Additionally, SMD switches are perfect for use in situations where automated manufacturing processes are desired.

You might choose an SMD switch for the following reasons:

- Space Constraints: In devices where you need to minimize the size of the components, SMD switches provide an excellent solution.

- High-Volume Production: If you are manufacturing in large quantities, SMD switches allow for faster assembly and lower costs.

- Improved Aesthetics: Their small size and sleek design contribute to more modern, stylish products.

- Durability and Reliability: For devices that need to withstand frequent use, SMD switches offer durability and a long lifespan.

While through-hole switches might be better suited for certain high-power or high-precision applications, SMD switches are the go-to option for many modern electronics.

SMD switches are a key component in modern electronic design, offering space efficiency, durability, and versatility. Whether you’re designing a smartphone, a home appliance, or a specialized piece of industrial equipment, choosing the right type of SMD switch can significantly impact the device’s performance and user experience. The compact nature of SMD switches allows manufacturers to create more functional, durable, and aesthetically pleasing products, while automated processes ensure cost-effective production.

If you’re considering SMD switches for your next project, remember their benefits and challenges. Understanding when and how to use them effectively will help you create the best possible design. Contact us for more information about switches.