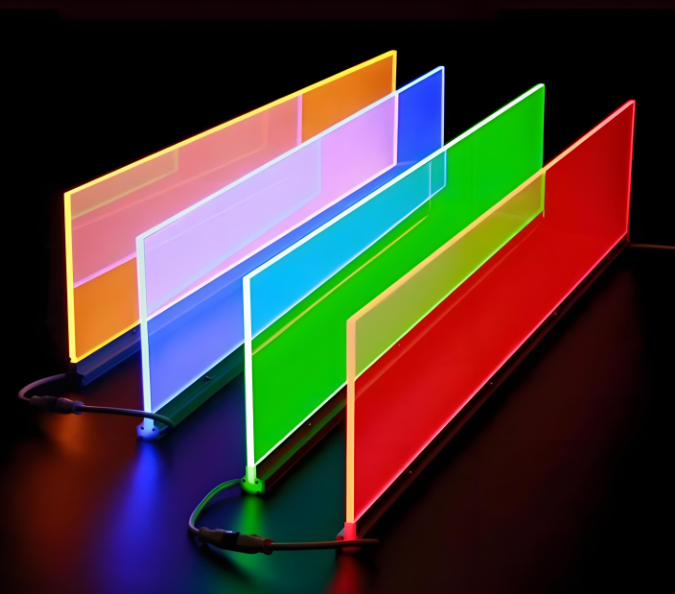

What Is Light Guide Film?

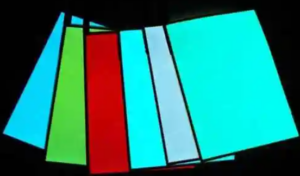

Light guide film (LGF) is a thin, flexible material that spreads light evenly across a surface. It helps devices look better by providing uniform lighting without bright or dark spots. This film is widely used in products like keyboards, control panels, and touch screens to improve visibility. It’s a smart solution for modern designs because it is lightweight, energy-efficient, and easy to use.

Unlike bulky lighting solutions, light guide film offers a sleek and effective way to brighten up devices. It makes things look clearer and more professional without adding extra weight. This is why many industries use it to enhance their products.

How Do Light Guides Work?

Light guide film works by taking light from a source, such as LEDs, and spreading it evenly. Tiny patterns inside the film help control how light moves and spreads. When light enters the film from the edges, it bounces around inside and is directed outward in a smooth and even way. This prevents uneven lighting and makes everything look well-lit.

The film works by using a simple concept called reflection. Light is trapped inside and only released through specific points. This clever design helps save energy while keeping brightness levels high. With fewer LEDs needed, devices using light guide film can last longer on a single charge.

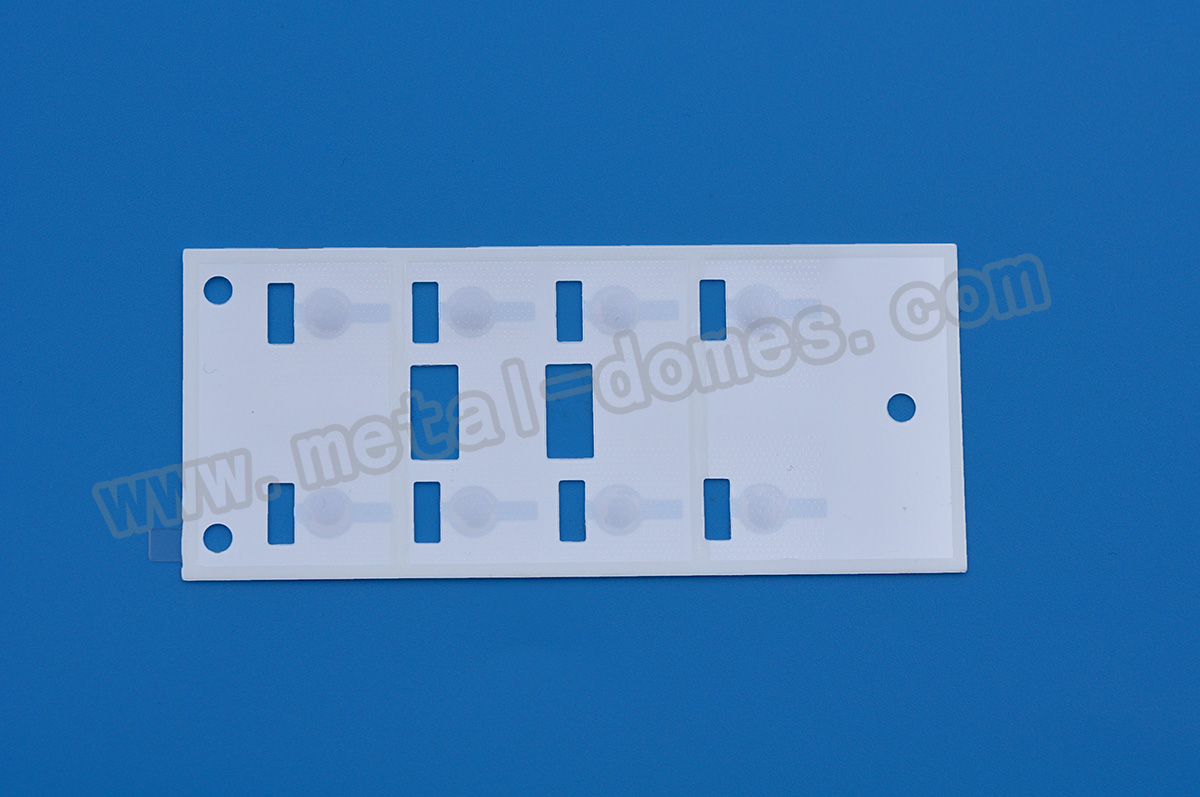

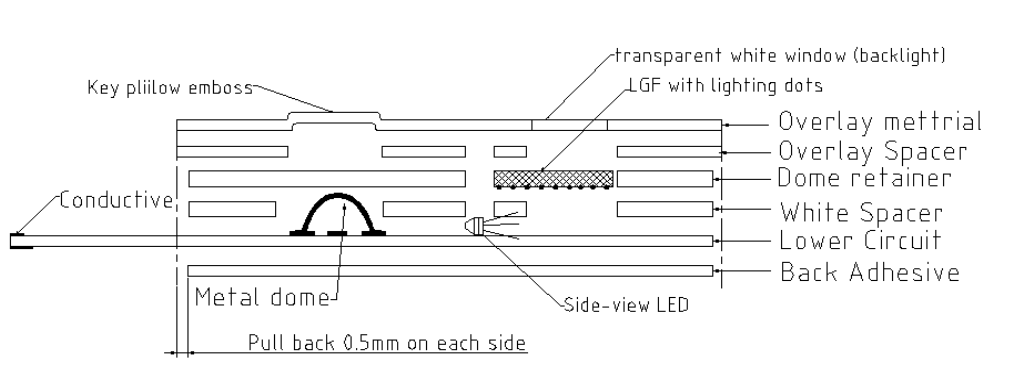

Structure of Light Guide Film

The structure of light guide film includes several essential layers that work together to provide efficient lighting and functionality. These layers are:

- Overlay Material – This top layer acts as a protective cover and provides a smooth surface for user interaction.

- Overlay Spacer – Positioned beneath the overlay, it ensures proper spacing and alignment of internal components.

- Dome Retainer – This layer holds the tactile domes securely in place, ensuring reliable button performance.

- White Spacer – It helps to reflect and distribute light evenly across the surface for better visibility.

- Lower Circuit – This functional layer carries electrical signals to enable device operation.

- Back Adhesive – The final layer that allows the film to be securely attached to different surfaces.

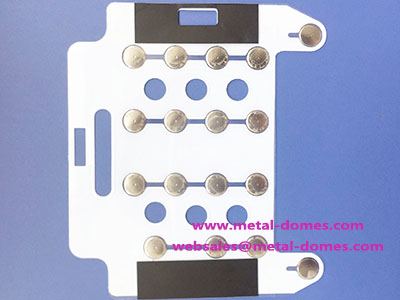

Advantages of Using Light Guide Film in Membrane Switch

Using light guide film in membrane switches offers several benefits that improve how devices work and look. Some of these benefits include:

- Slim Design – Light guide film is very thin, so it can be used in small devices without taking up much space. It’s perfect for modern gadgets that need to stay lightweight.

- Energy Saving – Since the film spreads light efficiently, fewer LEDs are needed. This helps devices use less power and last longer without charging.

- Even Lighting – The film ensures that every part of the switch is lit equally, making it easy to see in any lighting condition. This is especially useful in dark environments.

- Long-Lasting – The materials used in light guide films are strong and durable. They can handle frequent use without wearing out quickly.

- Flexible Design Options – The film can be customized to fit different shapes and sizes, making it suitable for a variety of products.

- Minimal Heat Generation – Light guide films don’t get hot like other lighting methods, making them safe for touchscreens and sensitive devices.

Where Can I Use Light Guide Film?

Light guide film is used in many products and industries because of its flexibility and efficiency. Some common applications include:

- Consumer Electronics – Devices like laptops, remote controls, and gaming keyboards use light guide film to brighten up buttons and touch areas. It makes them easier to use in low light.

- Automotive Industry – Cars use light guide films in dashboards and control panels to ensure drivers can see the controls clearly, even at night.

- Medical Equipment – Many hospital devices have lighted buttons to help healthcare workers operate them in dimly lit areas. Light guide film makes sure the buttons are easy to see.

- Household Appliances – Washing machines, ovens, and microwaves often have illuminated control panels that use light guide film for better visibility.

- Industrial Machines – Factories and workspaces use light guide films in control panels to improve safety and efficiency by making buttons and displays clear.

- Advertising Displays – Many signs and displays use light guide film to provide eye-catching, bright lighting that spreads evenly without harsh spots.

Since light guide film can be shaped and sized in different ways, it is useful in almost any product that needs clear, even lighting.

FAQs about Light Guide Film

1. Is light guide film expensive?

Not really. It can actually save money because it reduces the number of LEDs needed and helps lower power use.

2. Can light guide film be used in outdoor products?

Yes, it can. With the right protective layers, it can handle different weather conditions and last a long time.

3. Does light guide film wear out quickly?

No, it’s designed to be durable and can last for years with regular use.

4. Can light guide film be customized for different designs?

Yes, it can be made to fit different shapes, sizes, and lighting needs for various products.

5. Does light guide film work with all types of lights?

It works best with LEDs, but it can also be used with other light sources in some cases.

6. Is it easy to install?

Yes, it is lightweight and flexible, making it simple to add to devices without major changes.

7. Does it generate heat?

No, it stays cool even after long use, which makes it safe for sensitive devices and touchscreens.

8. What makes light guide film better than traditional lighting?

It spreads light more evenly, uses less energy, and takes up less space, making it a better choice for modern designs.