What Is UV Coated Membrane Keys?

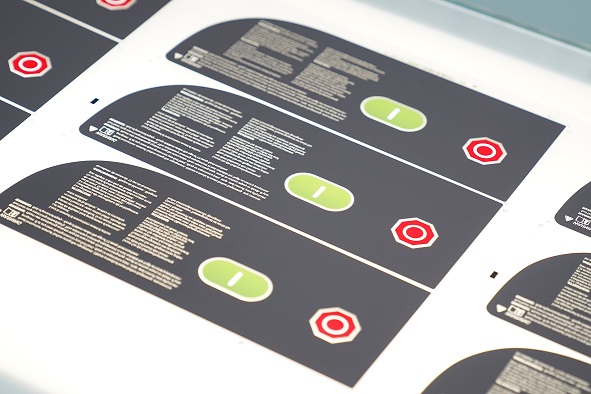

UV coated membrane panels are standard membrane keys with a protective layer of ultraviolet-cured coating. This coating is a thin, liquid polymer applied to the surface, which hardens when exposed to ultraviolet light. The process creates a durable, smooth finish that resists wear and tear.

Depending on the desired outcome, the coating can have a glossy or matte finish. Glossy coatings often give the keys a vibrant and shiny look, while matte finishes are preferred for a more subdued, professional appearance. The layer not only improves the aesthetic value but also serves as a protective shield against scratches, stains, and environmental factors like moisture and UV rays.

This coating is widely used in various industries, including electronics manufacturing, medical devices, and automotive controls, where membrane keys must endure frequent usage and harsh conditions.

What Does UV Coated Do?

- Scratch Resistance: Membrane keys are prone to scratches, especially when used in high-traffic environments. UV coating minimizes these marks, ensuring the keys remain visually appealing over time.

- Moisture Protection: Exposure to moisture can degrade membrane keys, especially in humid conditions. The UV layer acts as a barrier, preventing water or humidity from penetrating the surface.

- Fading Prevention: UV rays can cause colors to fade over time, especially in outdoor settings. A UV-coated surface resists fading, maintaining the vibrancy of the keys.

- Enhanced Appearance: Beyond protection, UV coating adds a refined look to the keys, making them appear polished and professional.

- Improved Tactile Feel: The coating adds a smoother texture to the keys, enhancing user interaction.

Is UV Coated Good?

The simple answer is yes. UV-coated membrane keys offer significant advantages in terms of durability, aesthetics, and overall performance.

- Prolonged Lifespan: The protective layer reduces wear and tear, meaning the keys stay functional for a longer time. This is especially beneficial in applications where the keys are used intensively.

- Cost-Effective Solution: While the initial investment in UV coating might seem higher, the long-term savings outweigh the costs. Fewer replacements and repairs mean reduced expenses over time.

- Adaptability: UV coating can be applied to various types of membrane keys, making it a versatile choice for different industries.

- User Satisfaction: Enhanced tactile feel and appearance contribute to a better user experience, ensuring satisfaction for customers and end-users alike.

- Environmental Protection: Modern UV coatings are designed to be eco-friendly, ensuring minimal environmental impact during the manufacturing process.

Does UV Coating Wear Off on Membrane Keys?

Like any protective layer, UV coating may wear off over time, especially under extreme conditions or constant use. However, the rate at which the coating degrades depends on factors such as:

- Quality of the Coating: High-quality UV coatings last longer and provide better protection.

- Frequency of Use: Keys used frequently will experience more wear compared to those used occasionally.

- Environmental Factors: Exposure to harsh conditions, such as extreme temperatures or direct sunlight, can accelerate wear.

With proper care and maintenance, UV-coated keys can last for years without significant degradation. Regular cleaning with non-abrasive materials and avoiding harsh chemicals can further prolong the coating’s life.

How Can I Coat UV on Keycaps?

Applying UV coating to keycaps is a specialized process that requires precision and the right tools. Here’s a step-by-step guide:

1. Clean the Keycaps and Printing Silver Paste: Begin by thoroughly cleaning the surface of the keycaps to remove any dirt, grease, or contaminants. This ensures the coating adheres properly.

2. Apply the Coating: Use a spray or dipping method to evenly apply the UV coating. Ensure that the layer is thin and uniform to avoid uneven finishes.

3. Cure Under UV Light: Place the coated keycaps under a UV light source to harden the coating. This step is crucial as it solidifies the polymer, creating the durable layer.

4. Inspect the Finish: Once cured, inspect the keycaps for any imperfections. If needed, additional layers can be applied for added protection.

5. Polish (Optional): For a glossy finish, the keycaps can be polished after the coating has cured.

For professional results, it’s best to use industrial-grade equipment and materials. If you’re attempting this process at home, ensure you follow safety guidelines and use quality products. If you are looking for a reliable membrane keys manufacturer, please take us as your go-to choice.

FAQs

1. Can UV coating be applied to all types of keycaps?

Yes, UV coating is versatile and can be applied to most keycap materials. However, it’s important to use a coating compatible with the specific material for optimal results.

2. How long does UV coating last on membrane keys?

With proper care, UV coating can last several years. Its longevity depends on the quality of the coating and the conditions under which the keys are used.

3. Is UV coating environmentally friendly?

Many modern UV coatings are designed with eco-friendly formulations, ensuring minimal environmental impact during production and application.

4. Does UV coating affect key sensitivity?

No, UV coating does not interfere with the functionality or sensitivity of membrane keys. In fact, it can enhance the tactile experience.

5. Can I apply UV coating at home?

While possible, applying UV coating at home requires careful handling and the right tools. For best results, professional application is recommended.