When it comes to user interfaces, metal domes and dome arrays play a critical role in ensuring smooth and reliable operation. These components are used in a wide range of applications, from keyboards to medical devices. In this blog, we’ll explore the concept of metal domes, the different series of domes, how they are manufactured, and the various applications they serve.

What is a Metal Dome?

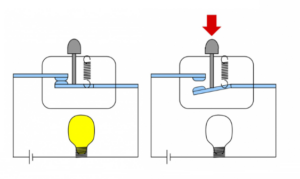

A metal dome is a small, spring-like device made from a thin sheet of metal. It’s shaped like an inverted dome, and when pressed, it compresses and makes contact with an electrical circuit to create a response. Metal domes are often used in tactile switches, providing feedback that lets users know when a button has been pressed. They are essential in many electronic devices, from simple keyboards to complex medical equipment, thanks to their reliability and compact design.

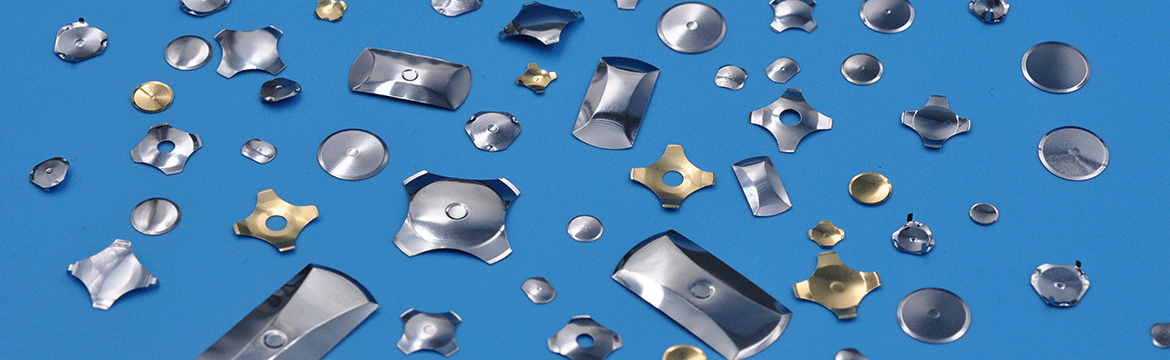

Series of Metal Domes

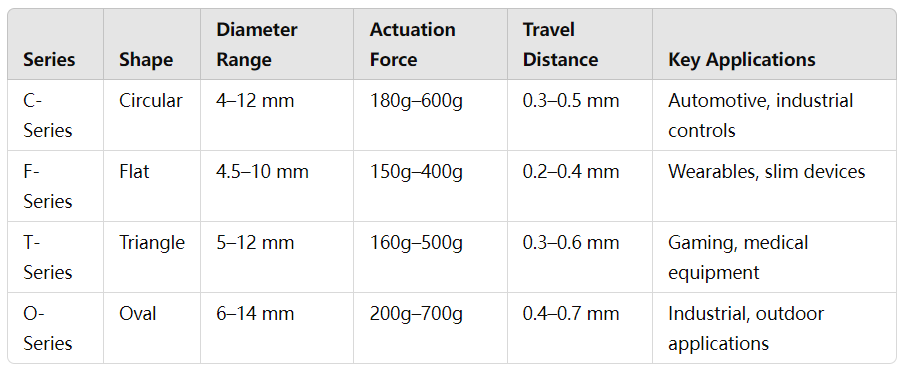

Metal domes are classified into different series based on their design, tactile response, and intended applications. Below is a detailed description of the four main series of metal domes, along with specific data to highlight their features.

- C-Series Metal Domes

Shape: Circular

Diameter Range: 4 mm to 12 mm

Actuation Force: 180g to 600g

Travel Distance: Approximately 0.3 mm to 0.5 mm

C-series metal dome picture:

Applications:

Automotive dashboards

Industrial machinery controls

Consumer remote controls

- F-Series Metal Domes

Shape: Flat or slightly domed

Diameter Range: 4.5 mm to 10 mm

Actuation Force: 150g to 400g

Travel Distance: Approximately 0.2 mm to 0.4 mm

F-series metal dome picture:

Applications:

Slim remote controls

Wearable devices

Compact keyboards

- T-Series Metal Domes

Shape: Triangle or cross

Diameter Range: 5 mm to 12 mm

Actuation Force: 160g to 500g

Travel Distance: Approximately 0.3 mm to 0.6 mm

T-series metal dome picture:

Applications:

Gaming controllers

Medical equipment interfaces

High-performance electronics

- O-Series Metal Domes

Shape: Oval or elongated

Diameter Range: 6 mm to 14 mm (long side)

Actuation Force: 200g to 700g

Travel Distance: Approximately 0.4 mm to 0.7 mm

O-series metal dome picture:

Applications:

Industrial control panels

Outdoor equipment

Rugged consumer devices

Features of Each Dome Series

Each series of metal domes has been engineered with specific features to meet different needs. Here’s a brief overview of what makes each series stand out:

- C-series: High spring force, excellent tactile feedback, long operational life, perfect for automotive and consumer electronics.

- F-series: Low profile, space-saving design, smooth actuation, ideal for handheld devices and remote controls.

- T-series: Precise tactile feedback, durable design, best for high-end electronics such as gaming controllers.

- O-series: Superior durability, wear resistance, and environmental protection, great for industrial and rugged environments.

How Is a Four-Legged Metal Dome Manufactured?

The manufacturing process of a four-legged metal dome involves several key steps to ensure precision, durability, and high-quality performance. Below is a detailed list of the typical process involved in creating a four-legged metal dome:

1. Material Selection

- Choose a suitable spring steel or stainless steel, which is thin enough to provide the required tactile feedback but strong enough for longevity.

- The material is chosen based on the specific requirements of the final product, such as flexibility, durability, and response.

2. Metal Sheet Preparation

- The metal sheet is cut to the desired size and shape. This is done with precision to avoid any defects in the final product.

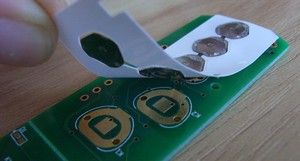

3. Stamping/Punching Process

- The metal sheet is stamped using a die to form the dome shape. This stamping process is designed to create the distinctive inverted dome shape that will act as the spring mechanism for the tactile switch.

- The stamping process can be fine-tuned to ensure that the dome’s curvature and height meet the desired specifications.

4. Adding the Four Legs

- After the dome is formed, four legs are attached to the base. These legs are strategically placed to ensure that they make proper contact with the circuit board when the dome is pressed.

- The legs can either be formed from the same sheet of metal or attached separately, depending on the design specifications.

5. Leg Alignment and Bending

- The four legs are bent into precise angles and aligned correctly to ensure the dome functions as intended.

- Each leg must be positioned accurately to provide stable contact and a reliable switch action when pressed.

6. Surface Treatment

- The metal dome is often coated or treated to improve its durability and resistance to corrosion. Common treatments include electroplating or coating with a layer of gold or nickel, especially for enhanced conductivity and long-term reliability.

7. Testing and Quality Control

- After manufacturing, each four-legged metal dome undergoes strict quality control testing. This may include measuring the actuation force, testing for durability, and checking the consistency of the legs’ alignment.

- The dome is tested to ensure it responds reliably and consistently with the expected tactile feedback when pressed.

8. Final Inspection

- A final inspection is carried out to ensure that the metal dome meets all of the required specifications for the application.

- Any defective units are removed from the production line to ensure only high-quality domes are shipped to customers.

9. Packaging and Shipping

- Once the metal domes have passed all tests and inspections, they are carefully packaged for shipping to clients or integrated into the final products.

Dome Applications

- Consumer Electronics: Metal domes are often found in remote controls, keyboards, and other electronic devices where tactile feedback is important.

- Automotive: In the automotive industry, metal domes are used in control panels, dashboards, and other touch-sensitive components where reliability and feedback are crucial.

- Medical Devices: In medical equipment, metal domes are used in user interfaces that require precise control and feedback, ensuring that the equipment works correctly even in critical situations.

- Industrial Equipment: Metal domes are also used in industrial environments, where they can withstand harsh conditions while providing tactile feedback for control systems.

- Gaming: In gaming controllers, metal domes are used to give players the responsive feedback they expect, helping to enhance the user experience.

- Appliances: Everyday appliances, such as washing machines and microwaves, also use metal domes to provide reliable button presses and tactile feedback.

Leading Dome Series Manufacturer – Best Technology

Best Technology is at the forefront of manufacturing high-quality metal domes and dome arrays. With years of experience, we specialize in offering a wide range of dome series designed to meet the needs of various industries. Whether you need durable metal domes for rugged industrial applications or precise feedback for high-end electronics, we provide tailored solutions to meet your specifications.

Our commitment to quality ensures that every product we manufacture goes through rigorous testing and quality control processes. We work closely with our clients to ensure the final product meets or exceeds their expectations. With Best Technology, you can trust that you are getting the best in terms of durability, performance, and customer satisfaction.

For more information on how we can help with your dome component needs, feel free to reach out to us at sales@metal-domes.com.