What is an EL Panel?

An Electroluminescent (EL) panel is a cutting-edge lighting technology that combines thinness, flexibility, and vibrant illumination. It is a sheet-like structure that emits light evenly across its surface when an electric current excites its phosphor coating. EL panels are made up of several layers, including a phosphor layer sandwiched between two electrodes, one of which is transparent. When powered, the electric field causes the phosphor to emit light.

They are lightweight and can be customized to fit different shapes and sizes, which makes them versatile for creative, industrial, and practical uses. Available in various colors, sizes, and designs, EL panels are frequently used in environments where traditional lighting options may fall short.

Are EL Panels AC or DC?

EL panels operate exclusively on alternating current (AC). This is because the phosphor materials inside the panel require high-frequency AC to produce light. Attempting to use direct current (DC) directly would render the panel ineffective. To address this, an inverter is typically used to convert a DC power source, such as a battery, into the required high-frequency AC.

The role of the inverter is crucial. It not only changes the power type but also regulates the voltage and frequency required for the EL panel. The brightness of an EL panel is often proportional to the voltage and frequency of the AC supply. However, operating the panel at excessively high voltages can reduce its lifespan. Therefore, using an appropriate inverter is essential for both optimal performance and longevity of the panel.

What Are the Uses of EL Panels?

The versatility of EL panels makes them popular across a wide range of industries. Below are some notable applications:

- Automotive Industry

EL panels are widely used in vehicle dashboards, where they provide backlighting for gauges and indicators. Their soft, uniform light enhances visibility without causing glare, making them ideal for night driving. These panels are also used in interior lighting to create a modern, aesthetic ambiance.

- Advertising and Signage

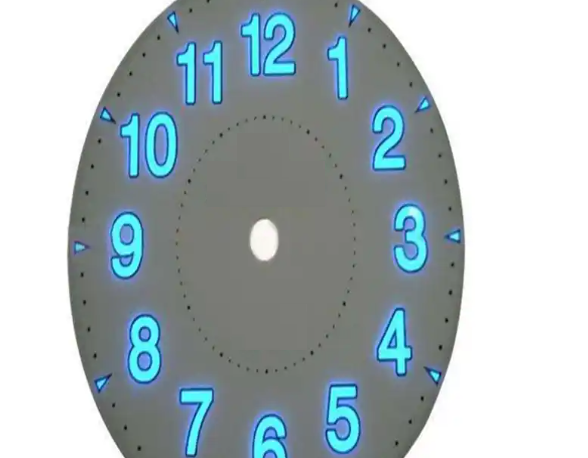

In advertising, EL panels are favored for creating eye-catching signs and displays. Their ability to produce bright, vibrant colors helps businesses attract attention to their products or services. EL panels are also used in animated signage, where different sections of the panel light up sequentially to create movement.

- Wearable Technology

In the fashion and wearable technology sectors, EL panels are used to create illuminated clothing and accessories. Their thin and flexible nature allows them to be integrated into fabric without compromising comfort or functionality.

- Architectural Lighting

EL panels are used to create sleek, modern lighting solutions in architecture. They can be installed in ceilings, walls, or furniture to provide ambient or accent lighting. Their slim profile and even illumination make them an excellent choice for spaces where traditional lighting fixtures would be intrusive.

- Art and Creative Projects

Artists and designers use EL panels for installations and creative projects, leveraging their ability to produce consistent, diffused light. These panels enable the creation of dynamic and interactive light displays that captivate audiences.

What Is the Difference Between LED and EL Panels?

While both LEDs and EL panels serve as lighting solutions, they have distinct differences in their structure, function, and applications:

Light Quality

EL panels emit a soft, uniform light that is ideal for backlighting and ambient lighting. In contrast, LEDs produce a more focused and intense light, which is better suited for directional lighting needs.

Energy Efficiency

LEDs are generally more energy-efficient than EL panels. They consume less power and have a longer lifespan, making them a cost-effective choice for continuous use. However, EL panels are preferred in scenarios where thinness and flexibility are more important than energy savings.

Size and Flexibility

EL panels are extremely thin and flexible, allowing them to be used in applications where space is limited or where the light source needs to conform to non-flat surfaces. LEDs, while available in small sizes, are typically rigid and require additional components like heat sinks.

Applications

EL panels excel in areas requiring even light distribution over a large surface, such as backlighting for displays or illuminated signage. LEDs, on the other hand, are often used in applications requiring high brightness, such as spotlights and flashlights.

Can I Cut an EL Panel?

Yes, most EL panels can be cut to specific sizes or shapes, making them highly customizable. However, this should be done carefully to maintain the panel’s functionality. EL panels have a layered structure, and cutting through the wrong section can sever the conductive layers, rendering the panel unusable.

Here are some tips for cutting EL panels:

- Only cut along marked guidelines or grid lines provided by the manufacturer.

- Use sharp scissors or a utility knife for clean cuts.

- After cutting, seal the edges using a protective coating or tape to prevent moisture from damaging the panel.

It’s important to note that some sections of the panel may become inactive after cutting. Always consult the manufacturer’s instructions before making any modifications.

How to Power an EL Panel?

Powering an EL panel involves using an inverter to convert DC from a power source into the high-frequency AC needed for the panel to function. The setup is relatively simple:

1. Connect the Power Source

Attach a DC power source, such as a battery or a DC adapter, to the inverter.

2. Connect the Panel

Connect the output terminals of the inverter to the EL panel using the provided connectors or soldered wires.

3. Turn on the Power

Switch on the power source to light up the panel.

When choosing an inverter, ensure it matches the specifications of the EL panel. Using an incompatible inverter can result in insufficient brightness or damage to the panel. For portable setups, battery-operated inverters are ideal. For stationary applications, AC-powered inverters provide a reliable solution.

What Is the Voltage of Electroluminescent Panels?

The operating voltage of EL panels typically ranges between 60V and 120V AC, depending on the size and design of the panel. Smaller panels often operate at the lower end of this range, while larger panels may require higher voltages to maintain consistent brightness across their surface.

The inverter used with the EL panel determines the exact voltage and frequency. Higher voltage and frequency generally result in brighter light output but may also reduce the panel’s lifespan. Therefore, it’s important to strike a balance between brightness and durability when choosing an inverter.

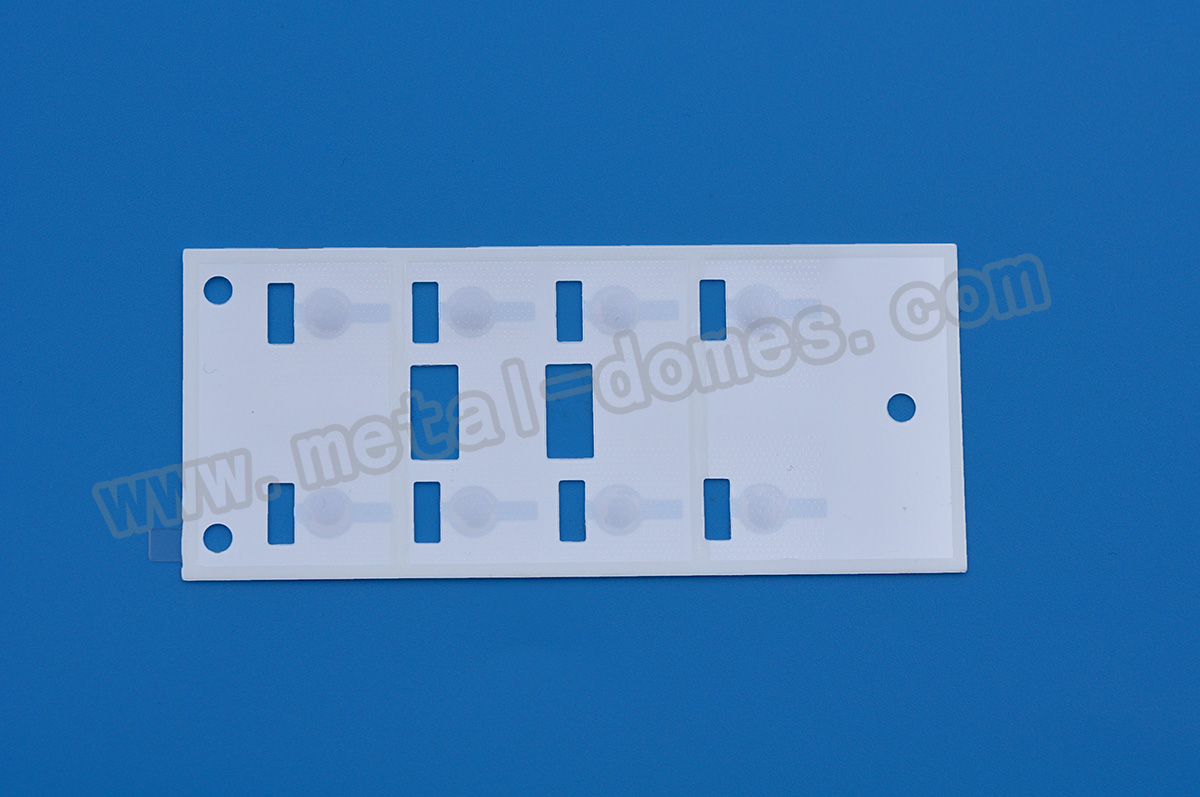

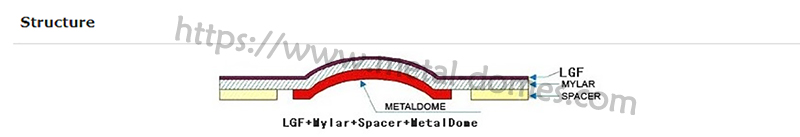

EL Panels vs. Light Guide Film

EL panels and light guide films serve similar purposes but differ significantly in their design and operation. Here’s how they compare:

Light Source

EL panels produce their own light using phosphors excited by an electric current. Light guide films, on the other hand, rely on an external light source, such as LEDs, to distribute light across their surface.

Uniformity

EL panels excel in providing even, consistent illumination across the entire surface. Light guide films achieve a similar effect by channeling and diffusing light from external sources, but the uniformity may depend on the quality of the film and the placement of the light source.

Flexibility

EL panels are thin and flexible, allowing them to be applied to curved or irregular surfaces. Light guide films are also flexible but are usually paired with rigid external lighting setups, which can limit their adaptability.

Power Requirements

EL panels need an inverter to convert DC into the high-frequency AC required for operation. Light guide films depend on the power requirements of their external light sources, which are often simpler and more energy-efficient.

If you’re looking for high-quality light guide film tailored to your needs, our company offers a wide range of options to meet your requirements. With our expertise and commitment to quality, we ensure that your lighting solutions are not only effective but also visually stunning. Contact us today to learn more about how light guide film can transform your projects.