What Is a Surface Mount Switch?

A surface mount switch is a type of switch that is designed to be mounted directly onto the surface of a printed circuit board (PCB). Unlike through-hole switches, which have leads that pass through holes in the PCB and are soldered on the other side, surface mount switches are soldered directly to the surface of the board. The surface mount switches are always used in applications where space is limited and high-density circuit board designs are required. Surface mount switches come in various shapes and sizes, and they can be used for a multitude of functions such as turning on and off power, selecting different modes or functions, and controlling the flow of signals in an electronic circuit.

Types of Surface Mount Switch

Surface mount switches come in various types to suit different applications.

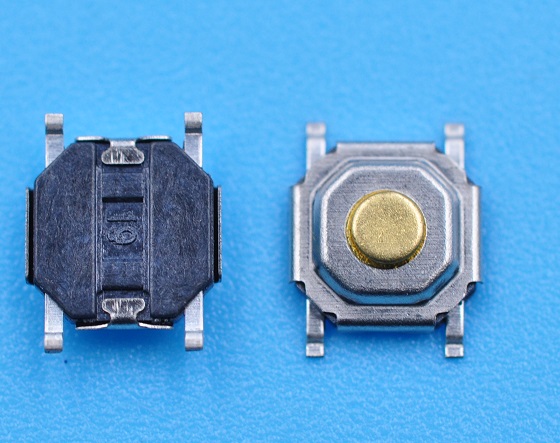

Tactile Switches

These switches provide a physical response or “click” when pressed, ensuring precise user feedback. They are common in consumer electronics such as remote controls and keyboards.

Slide Switches

Slide switches allow users to toggle between two or more settings by moving a small lever. Their low profile makes them suitable for slim devices.

Push Button Switches

These switches are activated by pressing and releasing a button. They are often found in handheld gadgets and appliances.

Rotary Switches

Rotary surface mount switches offer multiple positions, allowing users to select various options by turning a knob. They are used in equipment requiring adjustable settings.

Toggle Switches

Toggle switches are compact and durable, making them ideal for industrial and automotive applications.

Surface Mount Switch Voltage

Surface mount switches are available in a range of voltages to suit different applications. The voltage rating of a switch determines the maximum voltage that it can safely handle without breaking down or causing a malfunction. For example, a surface mount switch 12V rating is suitable for use in circuits where the voltage does not exceed 12 volts. It’s crucial to select a switch with the appropriate voltage rating to ensure the safety and proper operation of the circuit. In some low-power applications, such as in small battery-powered devices, switches with lower voltage ratings like 3V or 5V may be used. In contrast, in industrial or power electronics applications, higher voltage-rated switches, sometimes up to hundreds of volts, may be required.

Benefits of Surface Mount Switch

- Miniaturization and space saving: Because there are no exposed pins, the surface mount switch can be more compact mounted on the circuit board, thereby achieving product miniaturization and efficient use of space.

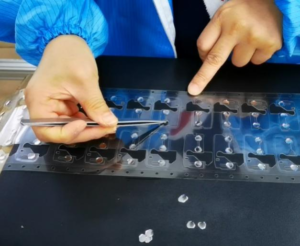

- Easy installation and maintenance: Surface mount switches can be automatically installed by attaching machine, while traditional pin switches need to be manually welded. In addition, service personnel can easily replace surface mount switches with soldering irons, which makes installation and maintenance much easier.

- Improved reliability: The SMD switch is connected to the printed circuit board through the solder joint. This connection method improves the reliability and anti-vibration capability.

- Environmental protection and safety: In line with global safety standards, such as ROHS and REACH certification, to ensure product environmental protection and safety.

- Low power: The maximum current of the SMD switch is 0.1A and the maximum voltage is 12V, which is suitable for low power application and reduces the energy consumption

Applications of Surface Mount Switch

Surface mount switches are used in a vast array of applications, they exist in everywhere we can see.

- In consumer electronics, they can be found in smartphones, tablets, wearable devices, and audio equipment. For example, the power button on a smartphone is often a surface mount tactile switch.

- In the automotive industry, they are used in dashboard controls, lighting systems, and various sensors and actuators.

- In industrial automation, surface mount switches are used in control panels for machinery, process control systems, and robotics.

- In medical devices, such as patient monitors and diagnostic equipment, where reliable switching and compact size are essential.

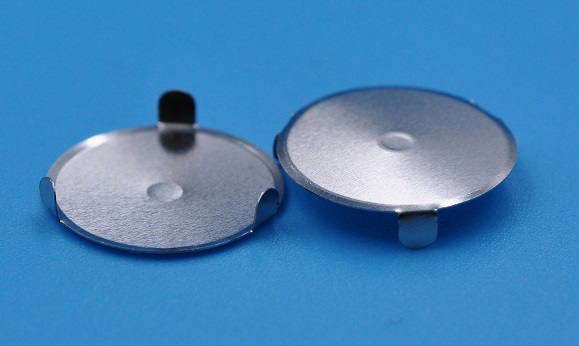

Surface Mount Switch vs. SMD Dome Switch

While surface mount switches are a broad category, SMD dome switches are a specific type within it. SMD dome switches are known for their small size and thin profile. They are often used in applications where space is extremely limited and a low-profile design is required.

SMD dome switches typically use a metal dome as a key component for electrical contact and tactile feedback. In contrast, other surface mount switches may use different mechanisms for switching and contact. For example, a rocker surface mount switch has a rocker arm mechanism, while an SMD dome switch relies on the deformation of the metal dome. SMD dome switches are commonly used in keypads of small electronic devices like calculators and smartwatches.

The Role of Metal Dome in a Surface Mount Switch

The metal dome is an essential component in many surface mount switches, particularly tactile ones. Its primary function is to provide tactile feedback, ensuring a clear and responsive operation when the switch is pressed. The dome is positioned over the contact area, where it bridges the circuit when depressed, allowing current to flow and completing the electrical connection.

- Enhanced User Feedback

The distinctive “click” generated by the metal dome is not just for user satisfaction—it serves a functional purpose. This feedback ensures that the user knows the input has been registered without needing to check a visual or audible confirmation. In applications like keyboards or control panels, this feature is invaluable for fast and accurate operation.

- Reliable Electrical Conductivity

Metal domes are made from highly conductive materials such as stainless steel or plated alloys. This conductivity ensures efficient signal transmission with minimal resistance. The dome’s precise placement and rapid actuation contribute to the switch’s reliability, reducing the risk of miscommunication or missed signals.

- Durability and Longevity

Durability is another key role of the metal dome. Its resilient construction allows it to endure repeated actuations over long periods. High-quality domes are tested to withstand millions of cycles, making them ideal for applications requiring high reliability. Their resistance to wear and tear reduces the need for frequent replacements, saving costs in the long term.

- Customizable Performance

The versatility of metal domes allows them to be tailored to meet specific application requirements. Variables such as actuation force, travel distance, and shape can be adjusted to suit different devices. For instance, a lighter actuation force is preferred for touch-sensitive devices, while a higher force might be chosen for industrial switches to ensure robustness.

- Sealing and Environmental Resistance

In some designs, metal domes contribute to sealing mechanisms, helping protect the internal components from dust, moisture, or contaminants.

How to Choose Suitable Metal Domes for Your Surface Mount Switch?

Selecting the right metal domes involves considering several factors:

- Size and Shape

Choose a size that fits the switch design without compromising performance. Common shapes include round metal dome, triangular, and oval.

- Force Requirement

Determine the actuation force needed for the application. Lower force suits light-touch operations, while higher force adds durability.

- Material Quality

Use high-grade materials like stainless steel for longevity and resistance to corrosion.

- Tactile Feedback

Ensure the dome provides clear feedback suitable for the application.

- Customization

Work with manufacturers to tailor domes to specific needs, ensuring optimal performance.

FAQs

- What is the lifespan of a surface mount switch?

The lifespan depends on the switch type and usage but typically ranges from 100,000 to 10 million cycles.

- Can surface mount switches handle high current?

They are designed for low to moderate current. High-current applications may require specialized switches.

- Are surface mount switches waterproof?

Some designs include seals or coatings to resist moisture, but not all are waterproof.

- What industries commonly use surface mount switches?

Consumer electronics, automotive, medical devices, and industrial equipment are primary users.

- How do I solder a surface mount switch?

Use reflow soldering for precise and efficient assembly. Manual soldering is possible but requires care.