How to make a metal dome? The first step in making a metal dome is to choose the right material. After determining the material, the next step is to design and plan the metal dome. During the design process, factors such as the shape, size, elastic coefficient, and installation method of the dome need to be considered to ensure that the dome can meet the needs of actual applications. Next, the metal dome can be processed and manufactured. Finally, the metal dome needs to be quality tested to ensure that the quality and performance of the metal dome meet the design requirements and usage standards.

What is metal dome?

A metal dome is a thin sheet-like component made of a metal material (such as stainless steel 301 or 304). It usually has a specific shape and size, can be deformed when subjected to external force, and quickly returns to its original shape after the external force is removed.

Metal domes are mainly used in membrane switches of rigid boards such as printed circuit boards, and are also widely used in membrane switches, contact switches, PCB boards, FPC boards, medical devices and other products.

Characteristics of metal dome:

High elasticity: metal dome can maintain stable rebound ability after repeated deformation.

Excellent conductivity: metal dome can quickly conduct the circuit when the key is pressed to realize signal transmission.

Low contact resistance: ensure good conduction effect of the circuit, reduce signal loss and energy loss.

Corrosion resistance: choose suitable metal materials (such as stainless steel), which can be used for a long time in harsh environment without corrosion.

Strong wear resistance: high hardness, strong wear resistance, can withstand long-term use without wear.

High precision: modern manufacturing technology enables metal dome to achieve extremely high size and shape accuracy.

Good stability: after rigorous design and testing, it can maintain stable performance under various working conditions.

Strong customizability: metal dome of different shapes, sizes and elasticity can be designed according to specific application scenarios.

How do you dome a piece of metal?

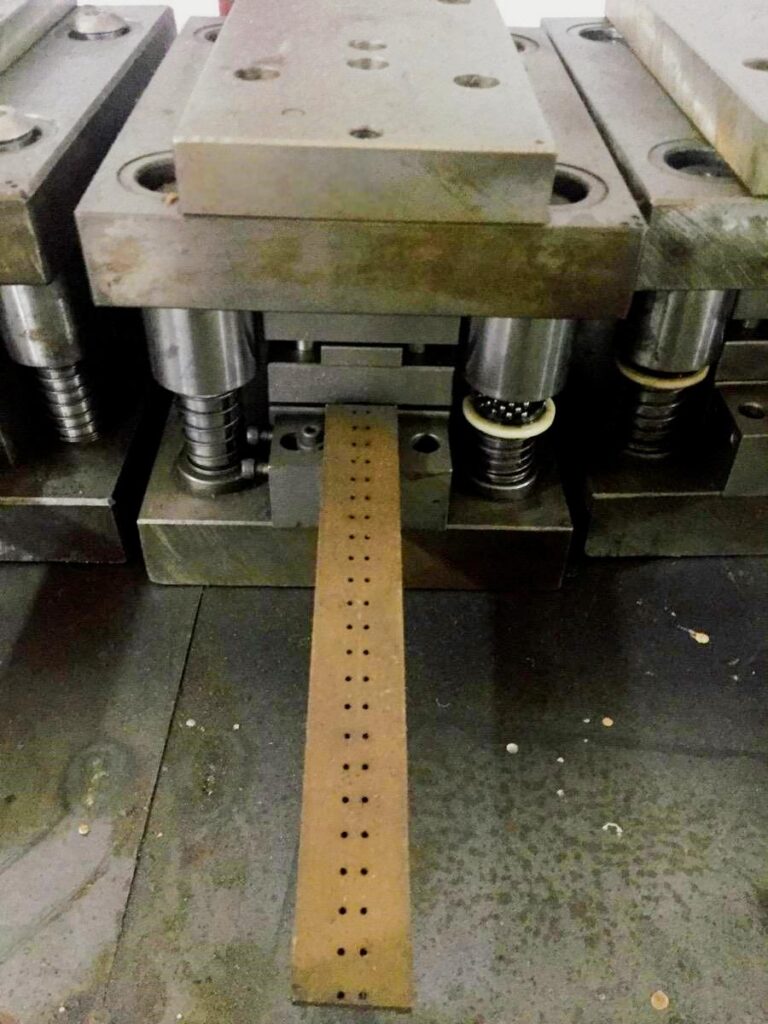

The main method of making a piece of metal into a dome is cold stamping through a stamping die. This method uses a die installed on a press to apply pressure to the metal material at room temperature, causing it to separate or plastically deform, thereby obtaining the required dome parts.

Steps and principles of cold stamping processing of stamping dies

Prepare materials: Select suitable metal materials, such as stainless steel or manganese materials, which have good processing properties after heat treatment.

Die design: Design the die according to the required dome shape and size to ensure that the die can accurately stamp out the required parts.

Stamping: Place the metal material on the press, and the die applies pressure to the material to cause plastic deformation or separation to form the required dome shape.

Subsequent processing: As needed, the stamped dome can be surface treated, such as nickel plating, silver plating, gold plating, etc., to improve its conductivity and corrosion resistance.

What is the strongest dome design?

The strongest dome design usually uses high-strength metal materials such as beryllium bronze, stainless steel, and spring steel.

- Beryllium bronze: Beryllium bronze has extremely high strength and elasticity and is one of the preferred materials for making dome. It not only has good mechanical properties, but also has excellent corrosion resistance and wear resistance, and is suitable for various harsh environments.

- Stainless steel: Stainless steel domes are usually made of high-strength stainless steel materials, such as 301 or 304 stainless steel. These materials have good corrosion resistance and high strength, and are suitable for application scenarios that require high strength and corrosion resistance.

- Spring steel: Spring steel is also commonly used to make domes. These materials have excellent elasticity and strength, and are suitable for occasions that require high elasticity.

How does metal dome work?

The working principle of metal domes mainly depends on their elasticity and conductivity. Metal domes are usually located in the conductive part of the PCB board. When pressed, the center point of the dome is concave and contacts the circuit on the PCB, thus forming a loop, and the current passes, allowing the entire product to work normally.

What is an ellipse shape dome?

An ellipse shape dome is an elastic metal sheet with an elliptical outline. Its major axis and minor axis are different in size, and the edge can be smooth and curved or have chamfers, small holes, slots, etc., which are designed for easy installation and use. It is often made of elastic metals such as stainless steel, phosphor bronze, beryllium bronze, etc., and is made by stamping or CNC processing, and may be subjected to surface treatment such as electroplating.

Elliptical dome has a variety of specifications and sizes, and common sizes include 7.6*8.9mm. These dome are usually used to connect circuits, switch operations, etc. to ensure the normal operation of electronic equipment.

Based on the principle of elastic deformation during operation, it deforms along the pressure direction when subjected to force, and the deformation characteristics in the long axis and short axis directions are different, which can store and release elastic potential energy. It can provide tactile feedback and trigger circuits in electronic device buttons, and can achieve elastic contact in electrical connections to ensure circuit conduction.

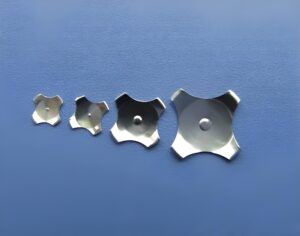

What are the different metal dome shapes?

- Round: The overall shape is round, with a center and annular parts, which can be evenly stressed and can be used for small pressure sensors.

- Square: The outline is a quadrilateral, which can be divided into square and rectangular, and the four corners can be processed. It is used for equipment that requires precise linear deformation.

- Triangle: It has three sides and three corners, with various types, and the top corner can be stressed. It is used for structures that are subjected to unidirectional force or angle guidance.

- Oval: Similar to an ellipse, it has a long axis and a short axis, and the elastic properties of the two axes are different. It is suitable for equipment that requires different elasticity in different directions.

- Cross: The shape is like a “cross”, consisting of two vertical long strips crossing each other, with four branches, and the end points can be stressed or fixed. It is used for equipment that contacts in multiple directions or provides elastic support.

In short, the production of metal dome requires multiple links such as material preparation, design and planning, processing and manufacturing, quality inspection, packaging and storage. Each link requires strict control of quality and process to ensure that the quality and performance of the metal dome meet the design requirements and usage standards.