What is a pressure switch tester? A pressure switch tester is a device specifically used to detect and calibrate the performance of a pressure switch. It can simulate various pressure environments and accurately measure parameters such as the operating pressure, return pressure, and switching difference of a pressure switch.

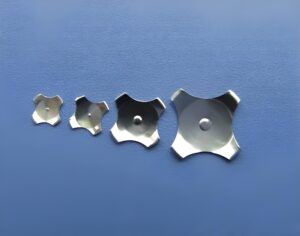

In a pressure switch, a metal dome is usually a part of a micro switch and plays a key role. When the deformation of the pressure-sensitive element is transmitted to the micro switch through a conversion mechanism, the metal dome will undergo elastic deformation according to the change in pressure. This deformation will cause the contact state of the micro switch to change, thereby achieving on-off control of the circuit.

The performance of the metal dome directly affects the accuracy and reliability of the pressure switch. If the metal dome is not elastic enough or the deformation is uneven, it may cause the operating pressure of the pressure switch to be inaccurate, or even cause misoperation or non-operation. Therefore, in a pressure switch tester, it is also very important to detect and evaluate the performance of the metal dome.

What is a pressure switch?

A pressure switch is an automatic control element that is mainly used to monitor and control pressure. When the pressure of the measured medium exceeds or falls below the preset value, the pressure switch opens or closes the contact through the deformation of the elastic element, thereby achieving control or protection of the measured pressure.

The working principle of the pressure switch is based on the elastic mechanical effect. When the medium pressure is applied to the elastic element, it will produce corresponding bending strain. By adjusting the stiffness of the elastic element and the preset trigger value, accurate control and detection can be achieved within different pressure ranges.

In the micro switch of the pressure switch, the metal dome is a common component. It mainly plays the role of assisting the on-off control of the circuit. When the conversion mechanism transmits the deformation of the pressure sensing element, the metal dome will undergo elastic deformation.

The elasticity of the metal dome can ensure that the contact state is accurately changed under appropriate pressure, and after the pressure disappears or returns to normal, it can rebound quickly to restore the micro switch to its original state.

Pressure switches are widely used in various automatic control systems, including home appliances such as air conditioners, refrigerators, and washing machines, as well as mobile equipment such as cars, ships, and airplanes. Its main function is to control or protect the corresponding system or equipment when the measured medium reaches a certain pressure.

In order to ensure the normal operation of the pressure switch and extend its service life, it is recommended to check and maintain it regularly:

Regularly check whether the contacts are in good contact: Make sure that the contacts are not oxidized or corroded, and clean or replace them if necessary.

Check the sealing performance: Make sure that the sealing ring of the switch is not aged or damaged to prevent medium leakage.

Calibrate the pressure setting value: Regularly calibrate the preset value of the pressure switch to ensure that it works within the correct pressure range.

Prevent overload: Avoid exceeding the rated working pressure of the pressure switch to prevent damage.

What is a pressure switch tester?

A pressure switch tester is a device specifically used to test the performance of a pressure switch. It simulates various pressure conditions and detects the working state of the pressure switch under different pressures to ensure that its performance meets the design requirements and usage standards.

The working principle of the pressure switch tester is based on the changes in the pressure sensor. When the pressure in the system is higher or lower than the set safety pressure, the disc in the sensor will move instantly, pushing open or close the switch connector through the connecting guide rod. When the pressure returns to the rated recovery value, the disc is immediately reset and the switch is automatically reset, thereby achieving the purpose of controlling the measured pressure.

Pressure switch testers are widely used in various industrial and automation systems to detect and control pressure. Such as:

Industrial automation: In industrial automation systems, pressure switches are used to control the flow of fluids and gases, and the tester ensures its stability and reliability under different working pressures.

Automobile manufacturing: In automobile manufacturing, pressure switches are used to control the cooling system and braking system of the engine, and the tester ensures its performance under extreme working conditions.

Aerospace: In the aerospace field, pressure switches are used to control the pressure and temperature in the cabin, and the tester ensures its reliability at high altitudes and extreme temperatures.

How do you check if a pressure switch is bad?

Turn on the pressure switch and observe whether the metal dome has signs of breakage, deformation or wear. The breakage of the metal dome is a more obvious damage. Once broken, it will definitely cause the pressure switch to not work properly. Slight deformation may affect the elasticity of the dome and the contact of the contacts, resulting in inaccurate action pressure or poor circuit contact.

Check the part where the metal dome contacts the micro switch contacts. If the contacts have obvious signs of wear, oxidation or ablation, it will affect the conductivity between the dome and the contacts. The oxide layer will increase the contact resistance, and ablation may cause the contact surface to be uneven, so that the dome and the contact cannot fit well, thus affecting the normal conduction and disconnection of the circuit.

You can use a small tool to gently press the metal dome to feel its elasticity. A normal metal dome should have obvious elastic recovery force and can quickly return to its original shape after pressing. If the elasticity of the dome is too weak, it may not provide enough force to make the contacts of the micro switch close or disconnect normally.

If there is a normal pressure switch of the same model, the elasticity of the suspected problematic metal dome can be compared with the normal metal dome. Under the same pressing force, observe whether their deformation degree and recovery speed are consistent.

What is the best way to test a pressure switch?

You can use a professional pressure calibrator, connect it to the pressure interface of the pressure switch, accurately apply pressure and compare the set value, detect the action, with high accuracy, suitable for high-precision control fields, but you need to pay attention to the interface sealing and correct operation. You can also use a simple pressure test device, which is low-cost and easy to operate, and is suitable for preliminary testing in general scenarios.

You can also use the resistance range of the multimeter to measure the normally closed and normally open contact resistances in different operating states of the pressure switch to determine the circuit connection and on-off. The operation is convenient, but before testing, make sure that the multimeter is normal and the right gear is selected, and pay attention to the electrical parameters of the pressure switch to prevent damage.

In short, the pressure switch tester is a very important testing and calibration equipment, which can ensure the accuracy and reliability of the pressure switch and ensure the safe operation of industrial production and equipment. When selecting and using the pressure switch tester, it is necessary to fully consider its function, accuracy, pressure range and other factors, and pay attention to the detection and evaluation of key components such as metal dome.