What is a marine switch panel? A marine switch panel is an operating interface installed on a ship to control various equipment and systems. It usually consists of a series of switches, buttons, indicator lights, etc., which can realize the operation of equipment operation, internal lighting and environmental control. When the marine switch panel adopts membrane switch technology, it brings many advantages to the operation and control of the ship.

BEST Technology specializes in the production of various types of membrane switch panels, supports the design and development of different types of membrane panel switches, and has rich design and manufacturing experience.

What is a marine membrane switch panel?

A marine membrane switch panel is a membrane switch panel designed and used for ships, with specific characteristics and application scenarios.

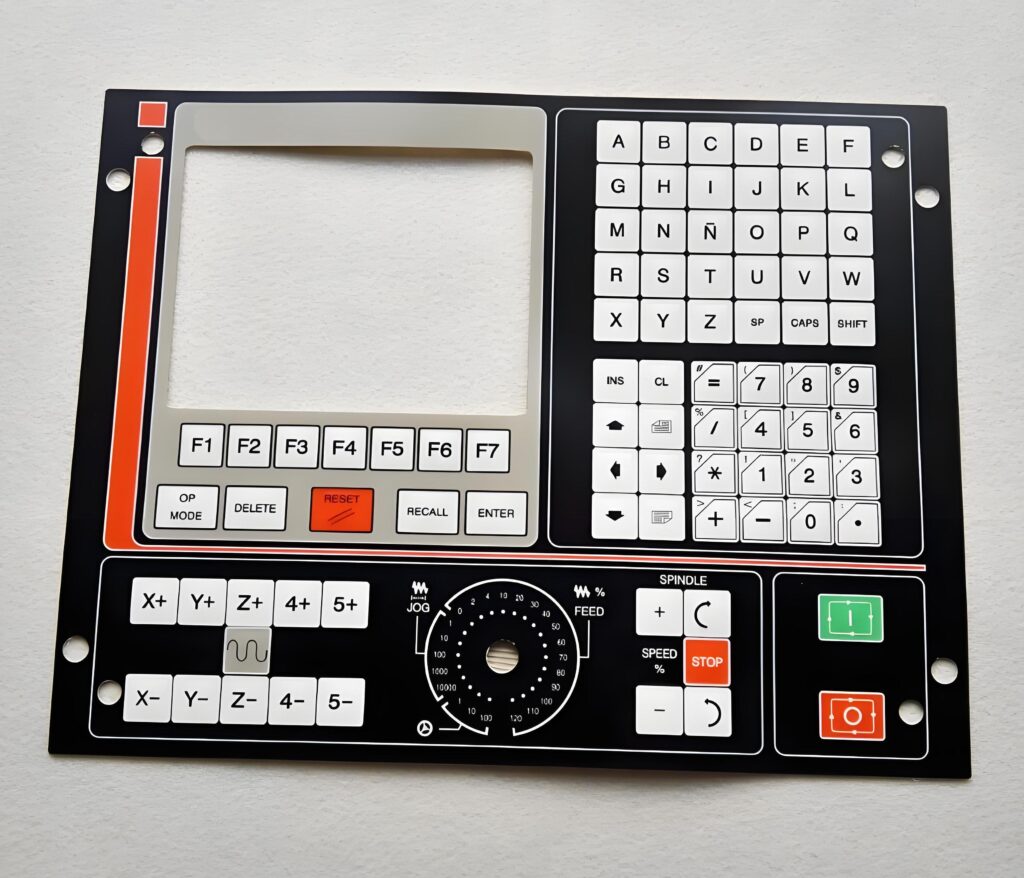

A marine membrane switch panel is an operating system that integrates key functions, indicator elements, and instrument panels. It consists of four parts: panel, upper circuit, isolation layer, and lower circuit.

When the panel is not pressed, the membrane switch is in a normal state, its upper and lower contacts are disconnected, and the isolation layer isolates the upper and lower circuits.

When the panel is pressed, the contact of the upper circuit deforms downward, overlaps with the lower circuit and makes the circuit conductive. The conductive circuit gives a signal to realize its corresponding function. When the finger is released, the contact of the upper circuit rebounds, the circuit is disconnected, and the loop triggers a signal.

Marine membrane switch panels are widely used in various control systems and instrument panels of ships. They are moisture-proof, corrosion-resistant, shock-resistant and highly sealed, and can work stably in harsh marine environments. They are small in size, comfortable to press, easy to replace and low in cost, and are suitable for the automation and intelligent control needs of various ships.

What types of marine switch panels are there?

The types of marine switch panels mainly include the following:

Ordinary push-button switch: suitable for simple power on and off control.

Ignition key switch: used to start the engine or motor operation.

Multi-function combination switch panel: contains multiple independent small switches, which can operate multiple devices at the same time.

LED indicator switch: It has an indication function and can also be used as a small contactor to drive the work of electrical equipment.

Automatic water level switch: used in monitoring and controlling water level and water flow.

Pressure sensor controlled electric valve switch: mainly used for regulating and managing liquid pressure.

Double-pole double-throw switch: or relay coil control circuit board small toggle switch, etc.

What is the manufacturing process for marine switch panels?

The manufacturing process of marine membrane switch panels mainly includes the following steps:

Cutting: separating raw materials from larger area and volume raw materials.

Film production: This is an important link, involving the setting of the screen printer and the selection of the screen to ensure the quality and efficiency of the screen printing.

Plate making: by coating the photosensitive paste on the screen printing screen, and then using the film to complete the plate making work on the platemaking machine.

Silk screen printing: This is the core process of thin film panel manufacturing, involving printing the design pattern on the panel.

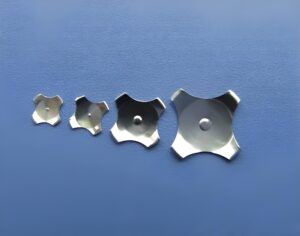

Mold production: using tools such as engraving machines, milling machines or laser cutting machines to make molds.

Cutting: using special tools and equipment to cut the shape of the thin film panel.

Assembly: Assemble the panel, surface glue, upper and lower lines, key glue and back glue into a whole.

Quality inspection: Perform quality inspection on the finished film panel to ensure that the product is qualified.

Material selection and characteristic requirements for marine membrane switch panel:

Panel layer: Usually use colorless and light-transmitting sheets such as PET or PC below 0.25MM, with high transparency, high ink adhesion, high elasticity, anti-folding and other characteristics.

Pad glue layer: used to closely connect the panel layer with the circuit layer, the thickness is generally between 0.02-0.05MM, with high adhesion and anti-aging properties.

Control circuit upper and lower layers: Use polyester film (PET), the thickness is generally within 0.05-0.175MM, and the most common is 0.125MM PET, and use a special process to screen print silver paste, carbon paste or gold paste to make it conductive.

Glue layer: PET double-sided adhesive is used, with a thickness of 0.05-0.2MM. When selecting materials, the overall thickness, insulation, feel of the circuit buttons and sealing of the product should be considered.

Back adhesive layer: Depending on the material to which the membrane switch is attached, ordinary double-sided adhesive, 3M adhesive, waterproof adhesive, etc. are often used.

These steps and material selections jointly ensure the manufacturing quality and performance of marine membrane switch panels.

What are the characteristics of marine switch panels?

The characteristics of marine membrane switch panels mainly include the following aspects:

Excellent sealing performance: The membrane switch is an integrally sealed part, and the contacts are not affected by the external environment. It can effectively prevent corrosion and oxidation, and at the same time prevent dust pollution, and is suitable for various harsh environments.

Small size and light weight: The weight of a general membrane switch ranges from a few grams to dozens of grams, and the thickness is generally about 1mm, which is very easy to carry and disassemble.

Beautiful: Modern silk screen printing technology allows membrane switches to be designed with various patterns and texts, and the appearance is beautiful and generous.

Strong durability: The membrane switch has a long service life, can withstand millions of press operations, and is not easy to wear.

Excellent conductivity: The circuit of the switch can be printed with carbon paste, silver paste, copper platinum, etc. The conductive layer can be folded at will and can withstand high-voltage electric shock without damaging its function.

Low cost: The price of the membrane switch is low and has a high cost performance.

Waterproof, oil-proof, anti-pollution, anti-static interference: Using special materials and technologies, the membrane switch has these protective functions and is suitable for various complex environments.

Good weather resistance and chemical resistance: It can maintain good performance within a certain temperature range and has good resistance to most chemicals.

These characteristics make the membrane switch perform well in the marine environment, can adapt to the complex environmental conditions at sea, and ensure the stable operation of the equipment.

Why Use a marine switch panel?

The main reasons for the use of marine membrane switch panels on ships include its simple structure, beautiful appearance, good environmental resistance and long service life.

First of all, the marine membrane switch panel has a simple structure and beautiful appearance, which can well adapt to the decorative style of the interior of the ship and enhance the overall aesthetics.

In addition, the membrane switch panel has good environmental resistance and can work stably in harsh environments such as humidity and vibration to ensure the normal operation of electrical equipment.

Secondly, the marine membrane switch panel has a long service life, which can reduce the frequency of maintenance and replacement and reduce the operating cost of the ship. Regular inspection and maintenance of the membrane switch panel, such as checking the appearance and wiring, cleaning the surface and interior, checking electrical equipment, fuses and protection devices, and grounding devices, can ensure its normal operation and service life.

Finally, the marine membrane switch panel has a wide range of applications on ships, which can control electrical equipment such as lights, motors, fans, etc., and improve the efficiency and safety of the ship.

In short, as an important part of ship control and operation, the performance and quality of the marine switch panel are directly related to the safety and operation efficiency of the ship. The marine switch panel using membrane switch technology has many advantages such as waterproof and moisture-proof, durable and reliable, beautiful plane, and convenient operation, and has been widely used in the field of ships.