Polyester dome is a dome mainly made of polyester material. Polyester dome has excellent elastic recovery ability. Compared with metal dome, polyester dome is relatively soft and will not produce too strong rebound force, thus providing users with a more comfortable operation experience.

What material is a dome made of?

Phosphor bronze, tin bronze: have good conductivity and wear resistance, suitable for application scenarios requiring high conductivity and wear resistance.

Stainless steel: have high elasticity, corrosion resistance and wear resistance, suitable for use in harsh environments. Stainless steel domes are usually nickel-plated or silver-plated to improve their conductivity and appearance.

Beryllium copper: have high elasticity, high strength and good conductivity, suitable for application scenarios requiring high precision and stability.

Spring steel: have high elasticity and fatigue resistance, suitable for occasions requiring frequent deformation.

Brass: have good conductivity and corrosion resistance, suitable for application scenarios requiring good conductivity and corrosion resistance.

Domes are widely used in many fields such as industry, military, electronics and daily life. Its ingenious design and diverse functions make it an ideal choice for mechanical transmission, electrical connection or disconnection, pressure sensing and other functions.

What is a dome array?

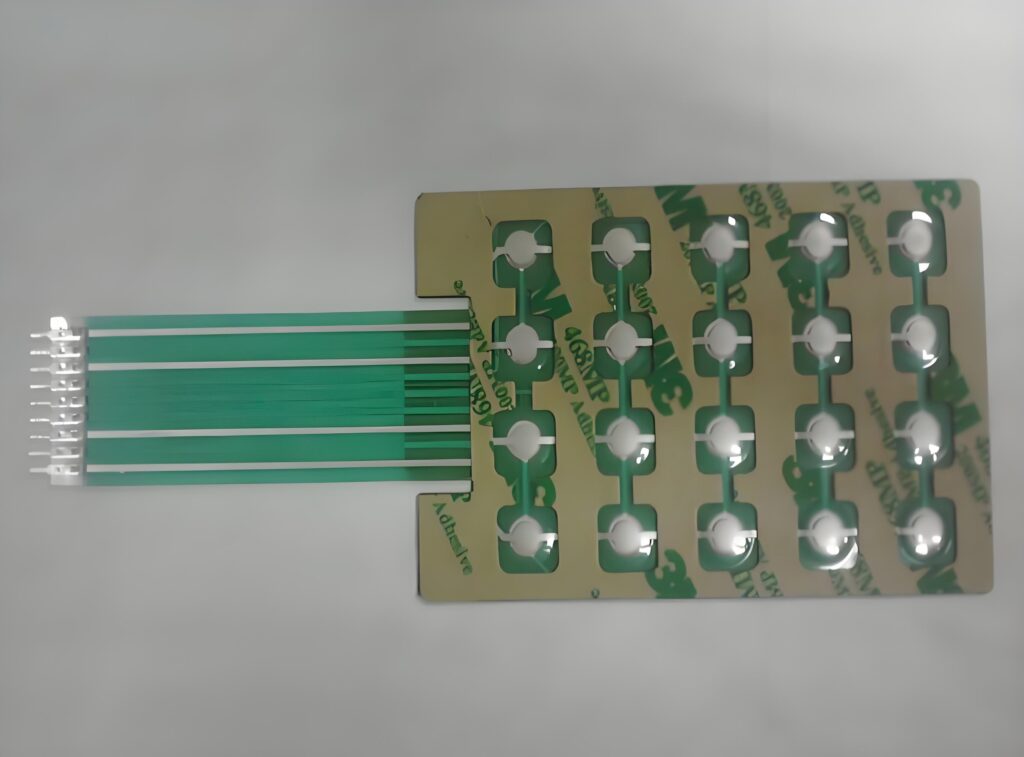

A dome array is a component structure formed by arranging multiple domes together according to certain rules and layouts. The position, spacing and arrangement of these domes in the array are usually designed according to specific application requirements.

The spacing between domes is an important parameter of the dome array. The size of the spacing depends on the size of the dome, the elastic range and the requirements of the application scenario. If the spacing is too small, the domes may interfere with each other during operation, affecting their normal elastic deformation and function; if the spacing is too large, it will waste space and increase the size of the device.

The domes in the dome array can be of exactly the same specifications or a combination of multiple specifications according to different functional requirements. When all domes have the same specifications, the manufacturing and installation are relatively simple, and they are mainly used to realize multiple contact points with unified functions, such as membrane switches with multiple buttons of the same function.

In the connection between circuit boards or the electrical connection inside electronic equipment, dome arrays can be used as a reliable connection method. Through the elastic contact between the dome and the contact point, good electrical conduction is ensured, and it can adapt to a certain degree of vibration, displacement, etc., to ensure the stability of the connection.

What is a Polyester Dome?

Polyester metal dome is a composite elastic element. Its structure is layered. The outer polyester layer protects, insulates and assists deformation, and the inner metal core provides elasticity. The two are closely connected by a special process. Polyester has excellent insulation, corrosion resistance and flexibility, while metal has good elasticity and (partially) high conductivity.

During operation, the external force first causes the polyester to deform and buffer, and then the metal leads the elastic deformation. After the external force is removed, the metal drives it to restore its original state. It is commonly used in electronic equipment buttons, electrical connection components and automotive electronic equipment. It provides reliable elastic feedback, stable electrical connection and other functions, adapts to complex working conditions and prolongs service life.

What does Polydôme consist of?

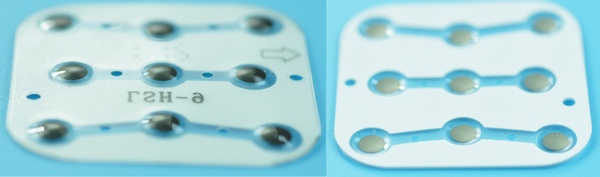

Similar to metal dome, polyester dome (Polydome) is also composed of three parts:

Mylar: Made of PET (polyester), located on the top of Polydome, the normal color is transparent, and conductive ink and gaskets can be seen. Normal thickness is 0.10mm and 0.125mm.

Conductive ink: Located under the raised semicircular area of ??Mylar, it is made of silver and carbon ink. The lower the resistance value of the conductive ink, the higher the percentage of silver, and vice versa. Silver thickness: 0.004-0.006mm; carbon: 0.005-0.006mm.

Spacer: Also made of PET (polyester), located at the bottom of Polydome, normal color is white or transparent. Regular thickness is 0.15mm, 0.20mm.

Rubber glue: Located on the top of Mylar, normal color is green, thickness is 0.125mm, can be firmly attached to silicone/rubber keys, membrane switch panels.

Bottom glue: In fact, if the customer wants to stick Polydome to the circuit board, the additional glue is already together with the Spacer, so that the glue cannot be separated from the Spacer.

Why use Polyester Dome?

Advantages of polyester film buttons (compared with conductive silicon buttons):

1. High reliability

2. Longer service life

3. Better click feeling

4. Design flexibility

5. Easier to assemble

Advantages of polyester film dome (compared with metal dome array):

1. Easy to recover after bending without affecting function

2. Lower material cost than metal dome

3. The same diameter dome has a larger adjustment range of force and stroke

4. Suitable for products that require smaller buttons and less pressure

5. PAD that does not damage the circuit can better protect the onboard circuit and extend the service life of the product

6. Easier to assemble

7. Excellent pressure stability

Disadvantages of polyester dome (compared with metal dome array):

1. Poor fatigue resistance and easy to damage after repeated operation.

2. Small stroke/stroke range

3. Low operating voltage/current

4. Large contact resistance

5. Small size

6. Short service life: metal dome >= 1 million times

7. Fixing performance: needs to be fixed to the product with screws.

8. The click feeling is not very good

9. The installation cost is high, and even the sample production requires tools

How Polyester Dome (Polydôme) works?

The polyester film dome will be placed above the PAD of the PCB, FPC or other circuit board. When the polyester film dome is pressed, the center point of the dome switch will be pressed down in the direction of the PAD of the circuit board, and the silver ink under the dome will be connected with the circuit on the circuit board, thus forming an electronic circuit, so that the circuit is closed and the entire product can work normally.

If you use Polydome with rubber glue, or glue on the bottom, the assembly method is roughly the same as that of the metal dome array.

Instructions for using Polyester Dome (Polydome)

1. Do not use it in a high temperature environment (>40?) for a long time, otherwise the polyester dome will lose its elasticity.

2. Do not use it in an extremely low temperature environment (<-25?) for a long time, otherwise it will affect the service life of the dome.

3. Do not use it outdoors for a long time.

4. Do not press the dome with sharp or hard objects.

As a new type of elastic element, polyester dome has good elasticity, corrosion resistance, insulation performance, light weight and high strength. The combination with metal dome has expanded its application field and improved its performance advantages.