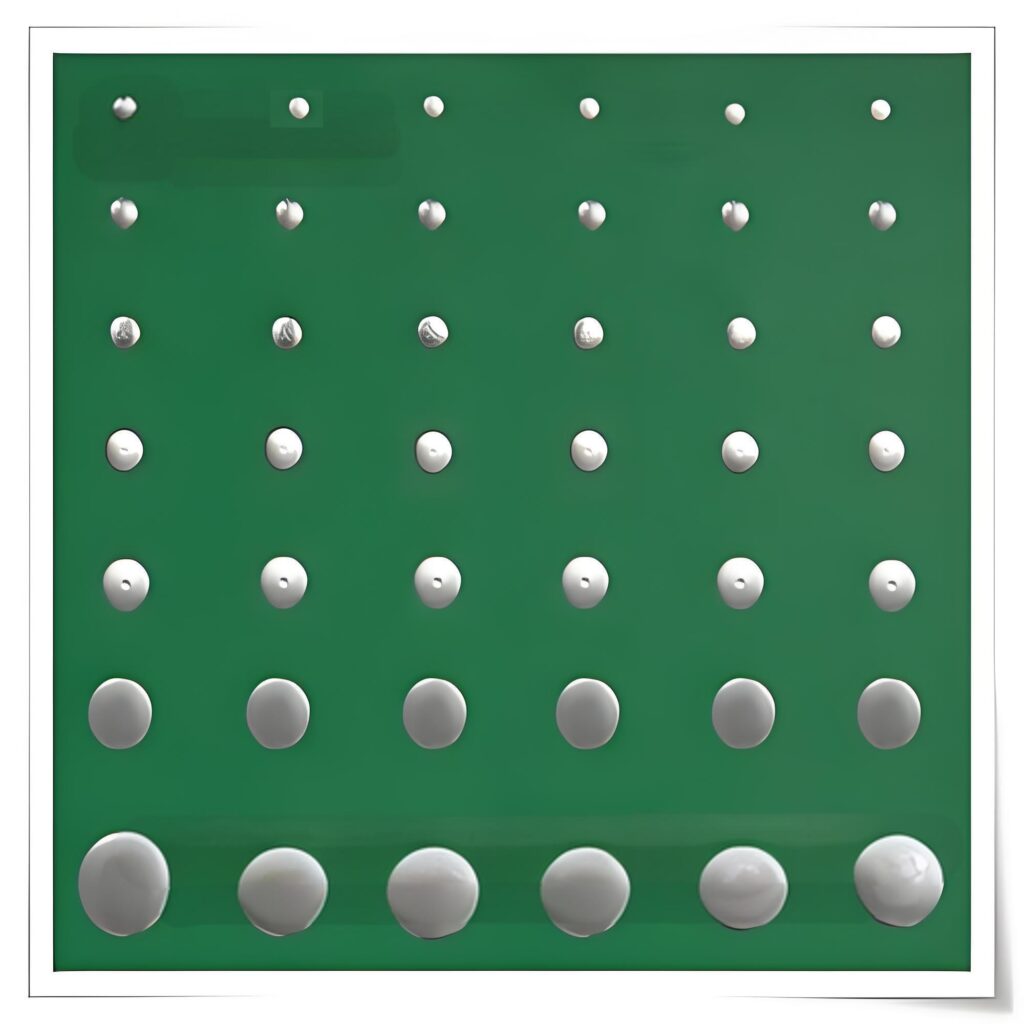

Adhesive sheet metal is to bond two or more layers of metal sheets together with a specific adhesive. Metal dome can be manufactured through precision machining processes with high-precision size and shape. This enables the metal dome to be accurately positioned and installed in the adhesive metal sheet, ensuring the stable performance of the adhesive metal sheet.

BEST Technology supports different numbers of metal dome to bond them to different materials, has multiple mounting lines, and supports small batch proofing design.

How to adhesive metals?

There are mainly the following methods of metal bonding:

- Welding: Welding is one of the most common methods of metal bonding. Commonly used welding methods include arc welding, TIG welding, etc. Welding can make metals tightly adhesive together.

- Glue: Different types of glue can be used for different types of metals. When using glue, it is necessary to remove oil and oxides on the metal surface to ensure the bonding effect.

- Screws: Screws are a common method for fixing metals. Screws are used to fix different parts together instead of tightly bonding metals.

- Rivets: Using rivets to fix two pieces of metal together requires the use of special rivet tools, which can provide a reliable connection.

- Bolts and nuts: Clamp two pieces of metal together with bolts and nuts. You need to drill holes in the metal and make sure the bolts and nuts are firmly tightened.

- Solder: Use solder to bond two pieces of metal together. It is suitable for some light applications, but the connection strength may not be as good as electric welding.

- Mechanical connection: Use mechanical methods such as threaded connection and slot connection to connect metals together, such as nuts and bolts, circlips, etc.

- Cold solder: Cold solder, also known as metal adhesive, is a special material that can bond different metals together. When used, just apply it to the metal surface and then connect the two metals together in a short time.

What is dome metal?

Dome metal, also known as metal dome, is a thin sheet of metal material (such as beryllium copper, stainless steel, spring steel, brass, etc.).

It has a specific shape and size, can be deformed when subjected to external force, and quickly return to its original shape after the external force is removed. This property makes metal dome perform well in achieving mechanical transmission, electrical connection or disconnection.

- High elasticity: metal dome can maintain stable rebound ability after repeated deformation.

- Excellent conductivity: metal itself has good conductivity, which can quickly conduct the circuit when the key is pressed to realize signal transmission.

- Low contact resistance: the contact resistance between the metal dome and the conductive contact is low, ensuring good circuit conduction effect and reducing signal loss and energy loss.

- Corrosion resistance: by selecting suitable metal materials (such as stainless steel), the metal dome can be used for a long time in harsh environments without corrosion.

- Strong wear resistance: metal dome has high hardness and strong wear resistance, can withstand long-term use without wear and tear, and extend service life.

- High precision: modern manufacturing technology enables metal dome to achieve extremely high size and shape accuracy to meet the needs of precision equipment.

- Good stability: after rigorous design and testing, metal dome can maintain stable performance under various working conditions.

- Strong customizability: metal dome of different shapes, sizes and elasticity can be designed according to specific application scenarios.

What is the best adhesive for metal to metal construction?

The adhesives commonly used for metal and metal structures have their own advantages and disadvantages, and there is no absolute best.

1. Epoxy adhesive

- Principle: It is like mixing two special things together. They will react and finally become a very strong, net-like thing that sticks the metal tightly.

- Advantages: It can stick the metal very firmly, not afraid of the erosion of various chemicals, and can also change some of its characteristics according to needs, such as making it softer or harder, and drying faster or slower.

- Disadvantages: It dries too slowly, sometimes it takes several hours or even several days to dry completely. Another thing is that it is brittle after drying, and it may crack if it encounters impact or vibration.

2. Acrylate adhesive

- Principle: Rely on something that can make it change quickly, so that it can quickly change from liquid to solid and stick the metal together.

- Advantages: It also has a certain resistance to changes in temperature and humidity, and it is not easy to fail due to environmental changes. It is also elastic and not easy to be pulled apart.

- Disadvantages: There will be a very pungent smell when sticking, which is not very comfortable to smell. When it encounters some organic solvents, it may not work well, and the viscosity will decrease.

3. Polyurethane adhesive

- Principle: The two main components interact to generate an elastic polymer to stick to metal.

- Advantages: It is very elastic and tough, can adapt to the deformation and vibration of metal, and will not break easily. Even if you apply force repeatedly, it can last for a long time. It can also be used normally in cold places without becoming hard and brittle.

- Disadvantages: It is very afraid of moisture. When the humidity is too high, it may not stick well or stick firmly. When it first sticks, the force is not very strong, and it takes a long time to achieve the best effect.

When actually using it, you should think carefully about what the metal is like, what kind of environment it will be used in, how strong it should be stuck, and how fast it can be done, and then choose the right adhesive. Moreover, before sticking, be sure to clean the metal surface, grind it, and remove all oil and dirt, so that it can stick well.

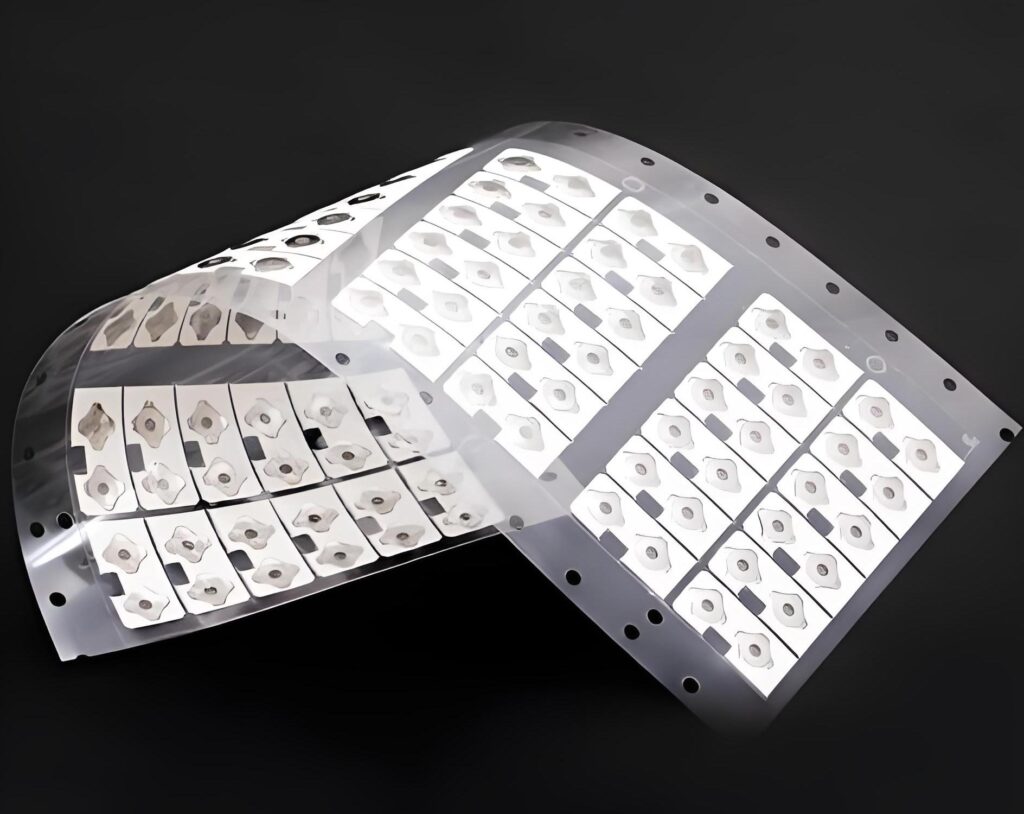

How to assemble metal dome on PET adhesive sheet?

To assemble metal domes on PET adhesive sheets, the following methods are usually used:

1. Manual assembly:

- Prepare tools and materials: PET adhesive sheets, metal domes, tweezers, glue, etc.

- Clean the surface: Make sure the surfaces of the PET adhesive sheets and metal domes are clean, free of oil and dust.

- Apply glue: Apply an appropriate amount of glue to the location where the metal dome needs to be installed on the PET adhesive sheet.

- Place the metal dome: Use tweezers to carefully place the metal dome on the location coated with glue, making sure that the dome is aligned with the adhesive sheet.

- Press and fix: Gently press the metal dome to make it fully contact with the PET adhesive sheet and ensure that the glue is evenly distributed.

- Wait for drying: According to the instructions of the glue, wait enough time for the glue to dry and cure to ensure that the metal dome is firmly fixed on the PET adhesive sheet.

- Use automated equipment: If large-scale production or improved assembly efficiency is required, consider using automated equipment, such as an automatic dome press. This machine can realize automatic feeding, positioning and pressing of dome, improving production efficiency and quality.

How to make a metal dome array?

The process of making a metal dome array can be divided into the following steps:

- Design: Use software tools to design according to the specifications, shape and size of the required metal dome array. Consider factors such as the material, thickness, elasticity, etc. of the dome.

- Material preparation: Select suitable metal materials, such as stainless steel, copper, etc. Ensure that the material has good elasticity and conductivity.

- Make molds: Make molds for metal dome arrays according to design requirements. The molds can be made using metal processing techniques such as milling and electrospark machining.

- Stamping or cutting: Put the metal material into the mold, and use equipment such as a stamping machine or laser cutting machine to stamp or cut to make a single metal dome.

- Surface treatment: Perform surface treatment on the metal dome, such as polishing, electroplating, etc., to improve its appearance and corrosion resistance.

- Assembly: Assemble the prepared metal domes according to the design requirements to form a metal dome array. Welding, bonding or other connection methods can be used.

- Testing: Test the prepared metal dome array, including elasticity test, conductivity test, etc., to ensure that its performance meets the requirements.

- Packaging: Pack the qualified metal dome array for transportation and storage.

It should be noted that the specific steps for making metal dome arrays may vary due to different design requirements and production processes. During the production process, operations should be strictly carried out in accordance with relevant standards and specifications to ensure product quality and safety.

Adhesive metal plates can combine the advantages of different metals. Different metal combinations and adhesives can be selected according to different application requirements to achieve customized performance. In adhesive metal plates, metal dome can provide additional strength and reliability to the material and increase the service life of the material.