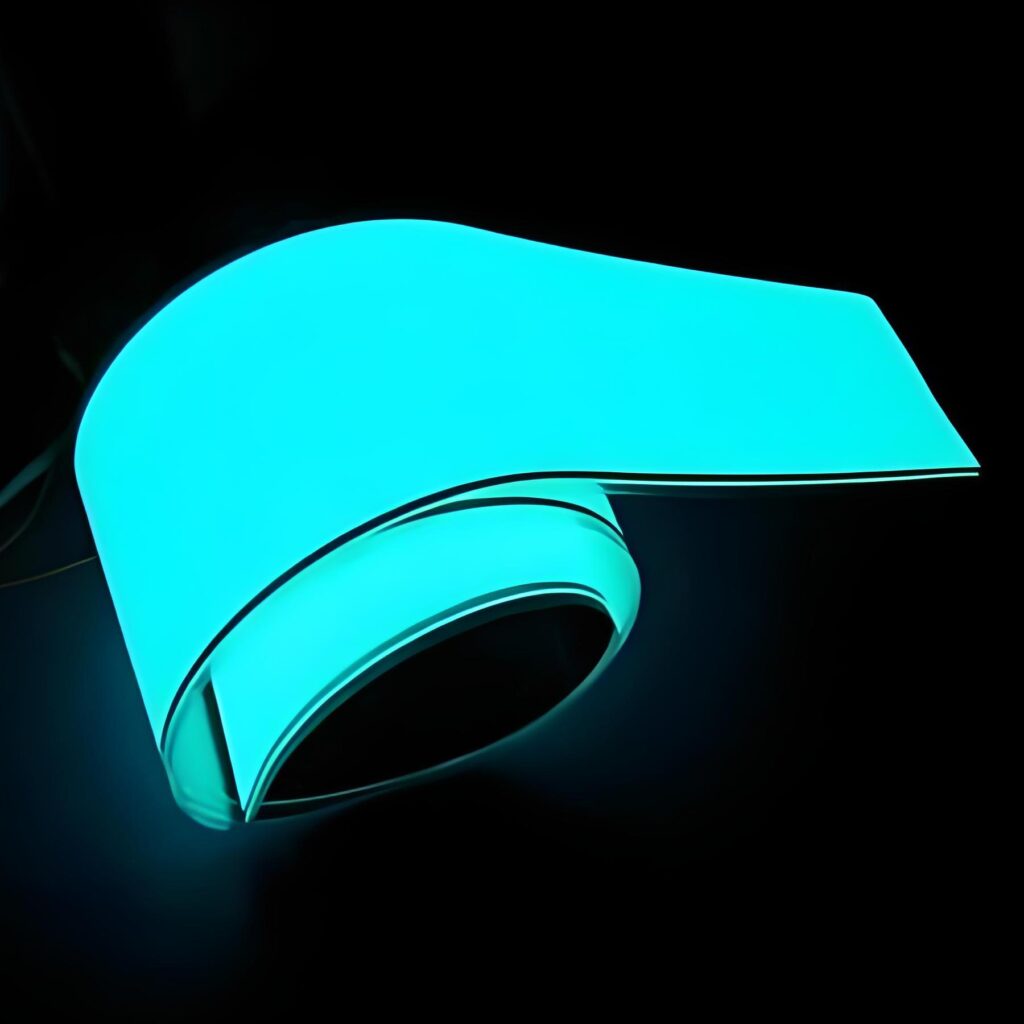

Electroluminescent panels are display devices that emit light through electric field stimulation. Electroluminescent panels are usually manufactured using thin film technology, and the thickness can be very thin, generally less than a few millimeters. At the same time, due to its light material, it is relatively light in weight, easy to install and carry.

BEST Technology is a company that has been focusing on the manufacture and assembly of membrane switches for many years. It can manufacture three types of backlight switches, electroluminescent (EL) backlight, fiber optic lighting and light guide film (LFG) lighting.

What is an Electroluminescent backlight?

Electroluminescent backlight (EL backlight) is a phenomenon in which electrons are excited by an electric field to hit the luminescent center, causing the electrons to jump, change, and recombine between energy levels to emit light. This backlight technology uses the voltage applied to the two electrodes to generate an electric field, and the electrons excited by the electric field bombard the luminescent center, thereby generating light.

Electroluminescent backlights are widely used in various fields, including electronic watches, car dashboards, etc. Due to its thin, flexible and strong characteristics, EL lamps have become an ideal choice for nighttime backlighting of vehicle dashboards. In addition, EL backlight is also used in LCD screens to provide a uniform backlight effect.

How do electroluminescent panels work?

The basic working principle of electroluminescent panels:

Electric field excitation: When the current passes through the electroluminescent material under the action of a DC or AC electric field, the electrons are excited and collide with the luminescent center, causing the electrons to jump, change, and recombine between energy levels, and finally release light energy.

Luminescence process: When electrons jump from a high energy level to a low energy level, photons are released, which are captured and imaged to form visible light.

Electroluminescence is an optical and electrical phenomenon, which is different from incandescent luminescence, chemiluminescence, sonoluminescence, etc. Electroluminescence is not accompanied by a violent heating process, but is directly converted into light energy through electrical energy, so it is called “cold light”.

What is the difference between LED and electroluminescent wire?

LED (light emitting diode) and electroluminescent wire are two different luminescent technologies, which differ in many aspects:

1. Light emitting principle

LED: LED is a semiconductor device, and its light emitting principle is based on the release of energy when electrons and holes in semiconductor materials recombine. Different semiconductor materials and doping components can produce light of different colors.

Electroluminescent wire: The light emitting principle of electroluminescent wire is the electroluminescent (EL) effect. It is mainly composed of a multi-layer structure such as a light-emitting layer, a conductive layer, and an insulating layer.

2. Appearance and structural characteristics

LED: LED is usually a small, independent light-emitting device with various packaging forms. The plug-in LED has two pins and looks like a small light bulb. There is a transparent or colored packaging shell on the outside, which can protect the internal chip and change the light-emitting angle.

Electroluminescent wire: The electroluminescent wire is a linear structure as a whole, which is usually soft and can be bent into various shapes. Its outer layer is generally a transparent plastic or rubber insulating layer, and the inner layer is a light-emitting layer and a conductive layer.

3. Luminous characteristics

LED: The brightness of LED can be adjusted by changing the current. Within the appropriate current range, the brightness is roughly linear with the current.

Electroluminescent wire: The light emission of electroluminescent wire is relatively uniform, and a relatively consistent luminous effect can be produced along the length of the wire. Its luminous intensity is relatively weak, and it is generally used to provide soft background light or decorative lighting, rather than for strong lighting purposes.

4. Energy consumption and efficiency

LED: LED is an efficient light-emitting device with high luminous efficiency, which can convert most of the electrical energy into light energy. Under the same brightness requirements, LED has lower energy consumption than traditional incandescent lamps and fluorescent lamps, and can effectively save energy.

Electroluminescent wire: The luminous efficiency of electroluminescent wire is relatively low, generally between a few lumens/watt and tens of lumens/watt. This means that when producing light of the same brightness, electroluminescent wire consumes more electricity than LED.

5. Application scenarios

LED: Due to its high brightness, adjustability and wide color range, LED is widely used in the field of lighting, such as indoor and outdoor lighting fixtures, car headlights, display screens, etc.

Electroluminescent wire: Electroluminescent wire is mainly used for decorative lighting and indication purposes. It can be used to decorate the outlines of cars, ships, and buildings to create a unique nighttime visual effect.

What are the disadvantages of electroluminescent lighting?

Electroluminescent lighting has the following disadvantages:

Limited luminous brightness: Compared with some common high-intensity lighting sources such as LED, the brightness of electroluminescent lighting is relatively low. It is not suitable as the main large-area high-intensity lighting equipment.

Limited color performance: Although electroluminescence can achieve luminescence of multiple colors, it can present relatively few colors in terms of color purity, saturation and color gamut range, which may not meet the needs of some application scenarios with extremely high color requirements.

Lifespan is affected by many factors: The luminous performance of electroluminescent materials will gradually decay with the increase of usage time, resulting in problems such as reduced brightness and color change, thus affecting its service life.

Susceptible to environmental influences: Electroluminescent materials are sensitive to factors such as humidity, oxygen, and ultraviolet rays in the environment. In a humid environment, the performance of electroluminescent materials may be degraded or even damaged.

What is the lifespan of the electroluminescent panel?

The service life of an electroluminescent panel is generally between 25,000 hours and 50,000 hours. The specific service life will be affected by many factors.

Factors affecting the service life of electroluminescent panels:

Ambient temperature: High temperature will accelerate the aging of electroluminescent panels and reduce their service life.

Voltage stability: Voltage fluctuations will damage electroluminescent panels.

Quality: Choosing high-quality electroluminescent panels can significantly increase their service life.

Ways to extend the service life of electroluminescent panels:

Maintain a stable ambient temperature: Control the ambient temperature through air conditioning or heat dissipation equipment to avoid high temperature damage to the electroluminescent panel.

Ensure voltage stability: Use a voltage stabilizer or voltage regulator to ensure voltage stability.

Choose high-quality products: Buy well-known brands and high-quality electroluminescent panels to reduce early damage caused by quality problems.

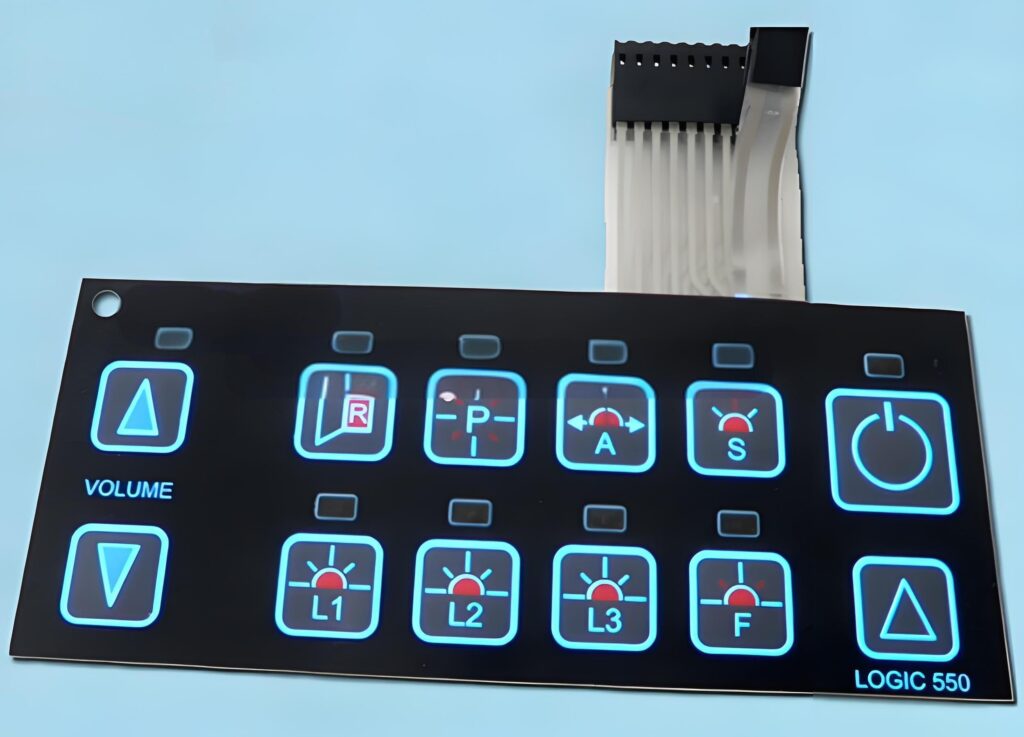

How to backlight a membrane or touch switch?

1. Preparation of materials and tools

Electroluminescent (EL) sheet: Choose the appropriate EL sheet according to the shape and size of the membrane or touch switch. It can also be cut as needed, but be careful to avoid damaging its internal structure.

Driving circuit: The EL sheet requires a special AC driving circuit, and its input is connected to a suitable power supply.

Glue: Such as transparent glue or double-sided tape, used to fix the EL sheet.

2. Setting steps

Connect the driving circuit: Connect the EL sheet electrode to the output end of the driving circuit to ensure a firm connection.

Fix the EL sheet: Use glue to fix the EL sheet tightly on the back or inside of the membrane or touch switch to avoid bubbles or wrinkles affecting the luminous effect.

Test and adjustment: Turn on the power to test the luminous effect. If it is uneven or the brightness is insufficient, check the output voltage of the driving circuit, or adjust the position and fixing method of the EL sheet, and pay attention to the influence of ambient temperature and humidity on its luminous performance.

As a new type of luminescent material with unique properties and broad application prospects, the combination of electroluminescent panels and membrane switches can provide membrane switches with richer functions and more beautiful appearance, bringing more innovations and possibilities to the development of the electronics field.